5083 Aluminum Coils for Sale - High Quality AA1100/AA1070 Aluminum Coils

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Thickness | 0.1mm-8mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm |

Width | 20mm-2500mm |

inner diameter | 76mm / 152mm |

Material | AA1050, AA1060, AA1070, AA1100, AA1235, AA3003, AA3004, AA3005, AA5052, AA5005, AA5754, AA5083, AA8011, AA8079, etc |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38, |

Surface | Mill finish / Coated |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 30-35 days after the receiving L/C or deposit |

2. Application of

(1) Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors, windows,

(2) Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations.

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS (if clients request, paid by client), MTC (plant provided), Certificate of Origin (FORM A, FORM E, CO), Bureau Veritas (if client request, paid by client), CIQS certificate and so on.

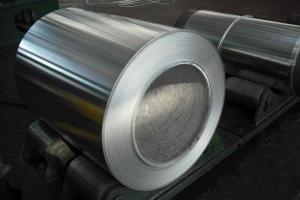

5. Image of

6. Package and shipping of

Eye to wall

Eye to the wall

With wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Depends on actual order, around 30 to 35 days

2) What is the QC system?

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the common surface repair methods for aluminum coils?

- There are several common surface repair methods for aluminum coils. One of the most common methods is mechanical repair, which involves sanding or grinding the damaged area to remove any corrosion or imperfections. This is typically followed by using a filler or putty to smooth out the surface and create a seamless repair. Once the filler has dried, the repaired area can be sanded again to ensure a smooth finish. Another common method is chemical repair, which involves using specialized chemicals to remove oxidation or corrosion from the surface of the aluminum coil. This can be done by applying the chemical directly to the damaged area and allowing it to react with the surface, breaking down any corrosion or oxidation. Once the chemical has done its job, the coil can be rinsed and dried, and any remaining imperfections can be addressed with mechanical repair methods. In some cases, heat repair methods can be used to repair aluminum coils. This involves using a heat gun or torch to heat the damaged area, allowing the aluminum to become soft and pliable. Once the metal is heated, it can be reshaped or manipulated to remove any dents or deformations. This method requires careful control of the heat to avoid damaging the coil further. Lastly, anodizing is a common surface repair method for aluminum coils. Anodizing involves applying a protective coating to the surface of the coil, which not only repairs any damage but also provides added protection against future corrosion or oxidation. This method is often used for more extensive repairs or when the coil is exposed to harsh environments. Overall, the choice of surface repair method for aluminum coils depends on the extent of the damage and the desired outcome. It is always recommended to consult with a professional or follow manufacturer's guidelines to ensure the best results and prolong the lifespan of the coil.

- Q: Aluminum inventory of the company, placed for a little longer, there will be surface oxidation, white spot shape, after cleaning into black spots, affecting the use of. Is there a better and convenient way to save it?

- Aluminum coil formation prevents oxidation of aluminum coils.In the aluminum coil chemical treatment to prevent oxidation of the surface of the aluminum layer to prevent corrosion, and increase after coating adhesion and corrosion resistance of the coating, conversion layer appearance color, golden yellow or green blue, the main function in ensuring the consistency of coating and film combination.

- Q: Describe the various uses of aluminum coils in the manufacturing industry.

- <p>Aluminum coils are widely used in manufacturing due to their lightweight, corrosion resistance, and strength. They are utilized in the production of various products such as automotive parts, aerospace components, and construction materials. Aluminum coils are also employed in the manufacturing of electrical wiring, heat exchangers, and packaging materials. Additionally, they are used in the production of cans and foils for food and beverage industries. Their versatility makes aluminum coils an essential material in many manufacturing processes.</p>

- Q: This question asks about the environmental impact of aluminum coils, which are commonly used in various industries.

- <p>Aluminum coils have both positive and negative environmental impacts. On the positive side, aluminum is highly recyclable, and its use in coils reduces the need for raw material extraction, thus conserving natural resources. The recycling process also consumes less energy compared to primary aluminum production, reducing greenhouse gas emissions. However, the production of aluminum coils involves energy-intensive processes that can contribute to carbon emissions. Additionally, if not properly managed, the waste from aluminum production can pollute water bodies and soil. Overall, the environmental impact depends on the balance between recycling and production practices, as well as waste management.</p>

- Q: Are aluminum coils suitable for marine applications?

- Indeed, aluminum coils prove to be fitting for marine applications. As a material resistant to corrosion, aluminum becomes an ideal option for deployment in marine settings that often encounter saltwater and other forms of corrosive elements. Lightweight, long-lasting, and boasting a high strength-to-weight ratio, aluminum coils hold significance in marine applications where weight reduction is sought after. Moreover, aluminum coils exhibit resilience in the face of extreme temperatures and possess commendable thermal conductivity, rendering them suitable for diverse marine heating and cooling systems. In summary, aluminum coils enjoy popularity in marine applications owing to their corrosion resistance, durability, and lightweight attributes.

- Q: Is it easy to bend aluminum coils and what factors affect their flexibility?

- <p>Aluminum coils are relatively easy to bend due to their malleability and flexibility. However, the ease of bending can vary depending on the alloy type, thickness, and temper of the aluminum. Thinner gauges and softer tempers are generally easier to bend. The process can be done manually or with machinery, and it's important to consider the coil's width and the radius of the bend to avoid cracking or other damage.</p>

- Q: What is the tensile strength of an average aluminum coil?

- The tensile strength of an average aluminum coil can vary depending on the specific alloy and manufacturing process used. However, commonly used aluminum alloys typically have a tensile strength ranging from 100 to 300 megapascals (MPa).

- Q: Is it possible to utilize aluminum coil as a conductor for speaker wires?

- <p>While it is technically possible to use aluminum coil as speaker wire, it is not recommended. Aluminum has higher resistance and lower conductivity compared to copper, which is the standard material for speaker wires. This can result in signal loss and reduced sound quality. Copper is preferred due to its superior electrical conductivity, ensuring minimal signal degradation over distance. For optimal audio performance, it's best to use speaker wire made from high-quality copper or copper-clad aluminum.</p>

- Q: Can aluminum coils be used for automotive body panels?

- Yes, aluminum coils can be used for automotive body panels. In fact, aluminum is a popular choice for car manufacturers due to its lightweight and corrosion-resistant properties, leading to improved fuel efficiency and longevity of the vehicle.

- Q: Can aluminum coils be used for magnetic purposes?

- No, aluminum coils cannot be used for magnetic purposes as aluminum is not a magnetic material.

Send your message to us

5083 Aluminum Coils for Sale - High Quality AA1100/AA1070 Aluminum Coils

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords