5182 Aluminum Coils - Big Rolls of Aluminum Coil Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

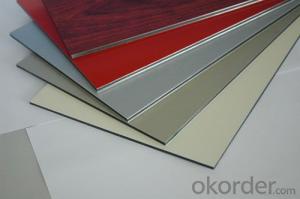

PEAluminum Coating Coils for ACP

Features of PE Aluminum Sheet:

1. Adopting precision rolling coatingtechnology, our PVDF and PE coated coil can ensure excellent adhesive withoutcoating omission.

2. For the PE coated aluminum coil weproduced, there are various colors for your choice.

3. Using infrared heating technology toprotect environment from pollution.

4. Our coated aluminum coil has four-rollercoating line, uniform coating thickness and good features.

RawMaterial of the PE Aluminum Coating Coils:

1.Aluminum Coil: high strength aluminum with alloy of AA1100 (aluminum alloy isavailable with AA3003, AA3005, AA5005 according to customer)

2. SurfacePaint: PE, PVDF and special paints.

Specificationof PE Aluminum Coating Coil

Width:20mm~1590mm

Thickness:0.06mm~1.0mm

ExternalDiameter: ≤ 1500mm

InternalDiameter: 405mm, 505mm, 150mm, 75mm

Coilweight: ≤ 4000kg

PE coatedaluminum coil is processed through the technics of roller coating and bakingwith precise polyester paints. Its color is glossy and with variety of colorsenabling you to choose easily. Chromatic aberration is small, impact resistanceis strong and easy to be processed, and all its performance has reached orsurpassed the national criteria. The products are widely used in indoor anddoor decoration, ceilings, room surface tiles, corrugated boards, wall panels, advertisement boards, counters,home appliances, decoration in and out of autos and boats.

Performanceof the coating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Colorof Card

PE (polyester)

PE

ColorMatch

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q: Which is better composite or aluminum, and what are some main differences between the two?

- I used the Easton Stealth Composite a few years back and it had the most pop of any bat I have ever used. I never seemed to miss the sweet spot, and I don't think it was necessarily because of MY skill.

- Q: What advantages does 0.1*100cm aluminum coil have? Is it suitable for the roof tiling? How is the anti-oxidation and anti-corrosion performance?

- It is seldom used as roof tiling because its performance is not as good as color steel panel and its cost is not cheaper than others.

- Q: What are the different coil transportation options for aluminum coils?

- There are several different coil transportation options available for aluminum coils. 1. Flatbed Trucks: Flatbed trucks are commonly used for transporting aluminum coils. These trucks have an open top and are equipped with a flat, open trailer bed. The coils are securely strapped or banded onto the bed to prevent any movement during transportation. 2. Coil Racks: Coil racks are specialized transportation equipment designed specifically for carrying aluminum coils. These racks are usually made of steel and are placed inside a truck or trailer. The coils are stacked on the racks, which have dividers to keep them in place and prevent any shifting or damage. 3. Coil Trailers: Coil trailers are trailers that are specifically designed for transporting aluminum coils. These trailers have a unique coil cradle system that securely holds the coils in place during transportation. The cradles are adjustable to accommodate different coil sizes and prevent any movement or damage. 4. Container Shipping: Aluminum coils can also be transported using shipping containers. The coils are loaded into the containers and secured using straps or bracing. This option is commonly used for international transportation, as containers can be easily loaded onto ships or trains. 5. Rail Transport: Rail transport is another option for transporting aluminum coils. Specialized rail cars, known as coil cars, are used for this purpose. These cars have cradles or racks built into them to securely hold the coils during transit. Rail transport is often used for long-distance transportation, as it is a cost-effective and efficient method. Overall, the choice of coil transportation option depends on factors such as distance, cost, and the specific requirements of the coils being transported.

- Q: Dongying power plant with 0.6mm thick insulation aluminum coil, manufacturers can be divided into small volumes?

- Tolerable。 The price depends mainly on what you need to split into.

- Q: What are the maintenance requirements for aluminum coils?

- To ensure optimal performance and longevity, aluminum coils require regular cleaning and inspection. It is recommended to clean the coils at least once a year, or more frequently in areas with high pollution or corrosive environments. Use a mild detergent or coil cleaner along with a soft brush or cloth to remove any accumulated dirt, dust, or debris from the coils' surface. Regular inspection is also crucial to identify any signs of damage, corrosion, or leakage. Bent fins, dents, or corrosion should be promptly addressed to prevent further harm and maintain coil efficiency. If there are any indications of leakage, it is essential to have a professional technician inspect and repair the coils to prevent potential refrigerant leaks. Additionally, it is advisable to keep the area around the coils clean and free from obstructions that may hinder airflow, such as leaves, plants, or debris. This will ensure proper airflow and prevent the coils from overworking, which can result in inefficiency and possible damage. In conclusion, maintaining aluminum coils involves regular cleaning, inspection for damage, corrosion, or leakage, and keeping the surrounding area clear for optimal performance and longevity. By following these maintenance practices, you can ensure the efficient functioning of the aluminum coils and extend their lifespan.

- Q: What are the common surface finishes for aluminum coils in the electrical industry?

- In the electrical industry, aluminum coils are commonly used for various applications such as transformers, motors, and electrical enclosures. These coils are often subjected to different surface finishing processes to enhance their performance and longevity. One of the most common surface finishes for aluminum coils in the electrical industry is anodizing. Anodizing involves creating a protective oxide layer on the surface of the aluminum through an electrochemical process. This layer not only provides excellent corrosion resistance but also improves the coil's durability and electrical insulation properties. Another popular surface finish is chemical conversion coating, also known as chromate conversion coating. This process involves treating the aluminum surface with a chemical solution to create a thin layer of protective coating. The coating not only provides corrosion resistance but also improves the adhesion of subsequent coatings or paints applied to the coil. Powder coating is another common surface finish used in the electrical industry for aluminum coils. It involves applying a dry powder onto the coil's surface and then curing it under heat to create a durable and attractive finish. Powder coating provides excellent resistance to chipping, scratching, and fading, making it ideal for applications where aesthetics and durability are important. In addition to these surface finishes, aluminum coils in the electrical industry may also undergo other treatments such as lacquering or painting. Lacquering involves applying a clear protective coating to the coil's surface, providing a glossy and protective finish. Painting, on the other hand, involves applying a colored coating to the surface for aesthetic purposes while also providing protection against corrosion. Overall, the choice of surface finish for aluminum coils in the electrical industry depends on the specific requirements of the application. Factors such as corrosion resistance, electrical insulation, durability, and aesthetics play a significant role in determining the most suitable surface finish for a given application.

- Q: Besides replacing all the aluminum wiring.

- Aluminum wire, in and of itself, is not the hazard. You can buy receptacles that are rated for AL/CU Aluminum and copper. If the wire is intact, replace the receptacle with an AL/CU rated receptacle, and be extra careful how much torque you put on the screws that hold the wire down. AN AL/CU rated receptacle costs around $3.50 compares to the cheap $0.59 copper only rated junkers at Home Depot? You do NOT have to replace all the aluminum wiring. In other cases, you can couple AL to CU wire with approved Wire Nuts that are rated for AL/CU. BE EXTRA CAREFUL ABOUT BEND RADIUS AND TORQUE SPECS!

- Q: Can aluminum coils be used in the production of railway tracks?

- The usage of aluminum coils in the production of railway tracks is not possible. Typically, railway tracks are manufactured using steel due to multiple reasons. Steel is renowned for its strength and durability, enabling it to endure the heavy loads and constant wear and tear caused by train traffic. Additionally, it exhibits exceptional heat resistance and can maintain its structural integrity even when exposed to high temperatures. This attribute holds significant importance for tracks that encounter friction and heat generated by moving trains. Conversely, aluminum possesses a lighter weight and lower strength compared to steel, along with inferior heat resistance. While aluminum may find application in other elements of railway infrastructure, such as electrical wires or specific train components, it is unsuitable for the actual production of railway tracks.

- Q: what is the final temperature of 250g of water whose initial Temperature is 25 C if 80-g of aluminum initially at 70 C is dropped into the water? The specific heat of aluminum is 0.215 cal/C g how do you do it? our teacher did not show us how and it is not in the book

- Given Data :-- Mass : Aluminium m(a) = 80 g, Water m(w) = 250 g Initial Temperature : Aluminium t? = 70 C and Water t?' = 25 C Final Temperature of both ( aluminium and water ) = T C (assume) Since Aluminium is initially at a temperature higher than that of water, it (aluminium) will lose heat to water . Heat lost by Al = Q = mass of Aluminium x sp.heat capacity of Aluminium x Temp. change = Q = 80 x 0.215 x ( 70 - T ) cal Heat gained by water = Q' = mass of water x sp.heat capacity of water x Temp. change = Q' = 250 x 1 x ( T - 25 ) According to principle of calorimetery . = Heat lost by aluminium = heat gained by water. = 250 x 1 x ( T - 25 ) = 80 x 0.215 x ( 70 - T ) = T = 27.9 C .... ( Rounded to one decimal place )...... Answer Answer .

- Q: How are aluminum coils used in the production of gutters and downspouts?

- Aluminum coils are used in the production of gutters and downspouts by being formed and shaped into the desired gutter or downspout profile. The coils are typically fed through a roll-forming machine that bends and molds the aluminum into the specific shape and size required. This process allows for the production of seamless gutters and downspouts, providing a more efficient and aesthetically pleasing solution for drainage systems.

Send your message to us

5182 Aluminum Coils - Big Rolls of Aluminum Coil Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords