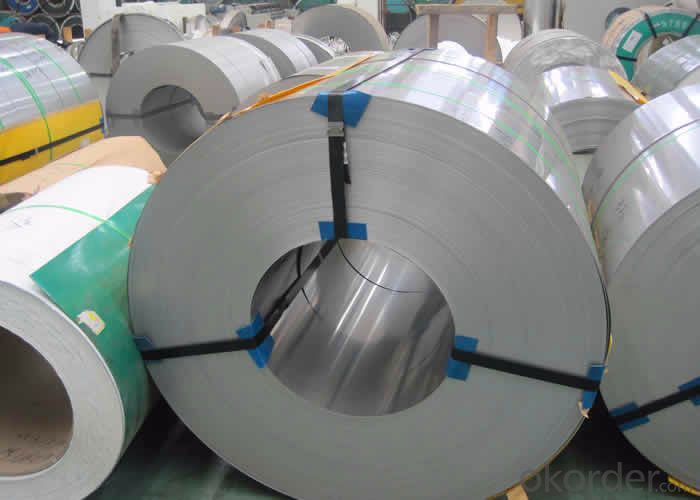

430 SERIOUS COLD ROLLED STAINLESS STEEL COIL

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,DIN,GB,JIS | Grade: | 400 series | Thickness: | 0.25-2.0mm |

| Place of Origin: | Guangdong China (Mainland) | Brand Name: | CMAX | Model Number: | SUS430 |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | 2B, BA, HL, NO.4 |

| Application: | Utensils, kitchenware, cutlery, pots & bowls, sinks, gas stove etc. | Width: | 800-1300mm | Length: | As requested |

| Market: | Asia, Mid East, South America etc. | Form available: | coil/ panel/ strip/ sheet | Sample: | Available |

| Packing: | PVC film with wooden pallet | Hardness: | From full hard to DDQ | Edge: | Mill edge/ Slitting edge |

| Feature: | Clean & corrosion resistance | Cr content: | 16%-18% | Steel type: | Ferrite stainless steel |

| Product name: | Cheap Cold Rolled Stainless Steel Coil 430 |

Packaging & Delivery

| Packaging Detail: | Standard export package, pvc film with wooden pallet. |

| Delivery Detail: | 15-30 days after receiving deposit |

Specifications

Cheap cold rolled stainless steel coil 430

Manufacturer

Origin: Baosteel, Tisco, Jisco

High technology & advanced equipment

Product Description

Cheap Cold Rolled Stainless Steel Coil 430 / ss430

| Item name | Cheap Cold Rolled Stainless Steel Coil 430 |

| Grade | 400 series |

| Type | Steel coil |

| Origin | CHINA |

| Standard | AISI,ASTM,DIN,GB,JIS |

| Thickness | 0.25mm-2.0mm |

| Width | 800-1300mm |

| Length | As requested |

| Surface treatment | BA, 2B, HL, No.4 |

| Edge | Mill edge/ slitting edge |

| Hardness | Full hardness to DDQ |

| Application | Utensils, kitchenware, cutlery, pots & bowls, sinks, food industry, construction decorations etc. |

| Package | Standard export package, PVC film with wooden pallet |

| Payment terms | T/T, 20% deposit in advance, balance against copy of B/L |

| Delivery time | 15-30 days after receiving the deposit |

- Q: Are stainless steel strips suitable for medical applications?

- Yes, stainless steel strips are suitable for medical applications. Stainless steel is known for its corrosion resistance, durability, and hygienic properties, making it ideal for medical instruments, implants, and surgical equipment. It can withstand high temperatures, is easy to clean, and can be sterilized, ensuring a safe and reliable option for medical use.

- Q: Are stainless steel strips magnetic?

- Yes, stainless steel strips can be magnetic or non-magnetic, depending on the specific type of stainless steel used. Stainless steel is an alloy that contains iron, which is inherently magnetic. However, the addition of certain elements such as nickel or manganese can alter the magnetic properties of stainless steel. Stainless steel strips that have a higher nickel content, such as the popular 304 or 316 grades, are generally non-magnetic. On the other hand, stainless steel strips with lower nickel content, such as the 400 series, can be magnetic. Therefore, it is important to consider the specific grade and composition of the stainless steel strip when determining its magnetic properties.

- Q: What are the common chemical compositions of stainless steel strips?

- Typically, stainless steel strips consist of iron, chromium, and nickel. The most common chemical makeup of these strips is 18% chromium and 8% nickel, which is known as 18/8 stainless steel. This particular composition offers excellent resistance to corrosion, making stainless steel strips suitable for a range of applications including kitchen utensils, automotive parts, and construction materials. Additionally, smaller amounts of other elements like carbon, manganese, and molybdenum may be present to enhance specific properties such as strength, formability, and weldability. The chemical compositions of stainless steel strips can vary depending on the specific grade and intended use, but the presence of chromium and nickel remains consistent across most stainless steel alloys.

- Q: How do stainless steel strips resist heat?

- Stainless steel strips resist heat due to the presence of chromium in their composition, which forms a protective oxide layer on the surface. This oxide layer acts as a barrier, preventing heat from penetrating the metal and providing excellent resistance to high temperatures.

- Q: What is the fracture toughness of stainless steel strips?

- The fracture toughness of stainless steel strips can vary depending on the specific grade and composition of the stainless steel. Generally, stainless steel has high fracture toughness due to its excellent resistance to cracking and ability to absorb energy before fracturing.

- Q: Can stainless steel strips be used in the production of marine equipment?

- Yes, stainless steel strips can indeed be used in the production of marine equipment. Stainless steel is a highly versatile and corrosion-resistant material, making it an excellent choice for marine applications. It offers excellent strength, durability, and resistance to saltwater, making it suitable for use in various marine equipment such as shipbuilding, offshore platforms, marine engines, and propellers. Stainless steel strips can be shaped, welded, and formed into different components and structures required for marine equipment, ensuring a long-lasting and reliable performance in the harsh marine environment.

- Q: Can stainless steel strips be used in the production of architectural fittings?

- Yes, stainless steel strips can be used in the production of architectural fittings. Stainless steel is a popular material in the architectural industry due to its durability, corrosion resistance, and aesthetic appeal. Stainless steel strips can be easily formed, welded, and fabricated to create a wide range of architectural fittings, including handrails, door handles, balustrades, and decorative elements. The versatility of stainless steel allows for the creation of both modern and traditional architectural designs. Additionally, stainless steel is low maintenance, making it ideal for architectural fittings that require long-lasting durability in various environments.

- Q: Can 111 stainless steel strips be etched or engraved for customization?

- Indeed, customization is possible for 111 stainless steel strips through etching or engraving. Stainless steel, being a versatile material, lends itself well to these processes, which can be achieved using different techniques like chemical etching, laser engraving, or mechanical engraving. By employing these methods, the stainless steel strips can be customized with utmost precision and intricate details, thereby offering limitless options for personalization or branding objectives. To achieve the desired outcome and identify the most appropriate technique for the specific customization requirements, it is advisable to seek guidance from a professional engraver or etcher.

- Q: Are 111 stainless steel strips susceptible to stress corrosion cracking?

- Stress corrosion cracking (SCC) can affect stainless steel strips with the crystallographic orientation of 111. However, it is crucial to consider that SCC is influenced by various factors, including the specific environment, applied stress levels, and the microstructure and composition of the material. Although 111-oriented stainless steel strips may display a higher resistance to SCC compared to other crystallographic orientations, they are not entirely immune to this form of corrosion. SCC occurs when a combination of tensile stress and a corrosive environment is present, resulting in material cracking. The susceptibility of 111 stainless steel strips to SCC can be affected by the presence of certain corrosive agents, such as chloride ions or hydrogen sulfide. These agents have the ability to infiltrate the passive oxide layer on the stainless steel surface, initiating and propagating cracks under applied stress. To minimize the risk of stress corrosion cracking in stainless steel strips, several precautions can be taken. These include selecting a stainless steel grade with enhanced resistance to SCC, avoiding exposure to corrosive environments, controlling applied stress levels, and implementing appropriate surface treatments or coatings. Additionally, regular inspection and maintenance procedures can aid in the detection of potential SCC signs and prevent further damage. In conclusion, the resistance of 111 stainless steel strips to stress corrosion cracking is not absolute and depends on multiple factors. Employing appropriate preventive measures and understanding the specific environment in which the material is utilized are crucial for reducing the risk of SCC.

- Q: Can stainless steel strips be used in power generation plants?

- Yes, stainless steel strips can be used in power generation plants. Stainless steel is a versatile and highly durable material that is resistant to corrosion, heat, and pressure, making it ideal for various applications in power generation plants. One common use of stainless steel strips in power plants is for the fabrication of heat exchangers. These devices are crucial for transferring heat from one medium to another, such as converting steam into electricity. Stainless steel's resistance to corrosion and high-temperature environments makes it an excellent choice for heat exchanger tubes, ensuring their longevity and efficiency. Stainless steel strips are also utilized in the construction of various components in power plants, including valves, pumps, and piping systems. The material's strength, resistance to corrosion, and ability to withstand high-pressure environments make it suitable for these critical applications. Furthermore, stainless steel strips are often used in the manufacturing of turbine blades and other parts in steam and gas turbines. These components are exposed to extreme temperatures and high mechanical stresses, and stainless steel's ability to retain its strength and shape under such conditions makes it a reliable choice. In addition to its physical properties, stainless steel is also favored in power generation plants due to its hygienic properties. It is easy to clean and maintain, ensuring that the equipment remains free from contaminants and does not compromise the plant's operations. In conclusion, stainless steel strips are commonly used in power generation plants due to their corrosion resistance, high-temperature tolerance, strength, and hygienic properties. From heat exchangers to turbine components, stainless steel is a versatile material that contributes to the efficiency and reliability of power generation processes.

Send your message to us

430 SERIOUS COLD ROLLED STAINLESS STEEL COIL

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords