4130 30CrMo SCM430 Alloy Structure Steel Round Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

4130 30CrMo SCM430 Alloy Structure Steel Round Bar

Product Description of 4130 30CrMo SCM430 Alloy Structure Steel Round Bar

1. Steel grade: ASTM4140, SCM440, 42CrMo, DIN1.7225

2. Length: 6M-12M

3. Diameter: 16mm-300mm

4. Product range: round bar, flat bar, square bar

5. Technique: Hot rolled, forged, cold drawn

Specification of 4130 30CrMo SCM430 Alloy Structure Steel Round Bar

Material | SCM4140 | Round bar | Dia(mm) | 16-300mm |

Process | EAF + LF + VD + Forged + Heat Treatment (optional) | Length (mm) | Max 12m | |

Heat treatment | Normalized / Annealed / Quenched / tempered | Flat bar | Thickness(mm) | 8-500mm |

Delivery condition | Hot forged +Rough machined (black surface after Q/T)+ Turned (optional) | Width(mm) | 70-200mm | |

Test | Ultrasonic test according to SEP 1921-84 D/d | Length (mm) | Max 12m |

Chemical Composition of 4130 30CrMo SCM430 Alloy Structure Steel Round Bar

C | Si | Mn | Cr | Mo | P | S |

0.38~0.43 | 0.15~0.35 | 0.75~1.00 | 0.8~1.1 | 0.15~0.25 | ≤0.035 | <0.04< td=""> |

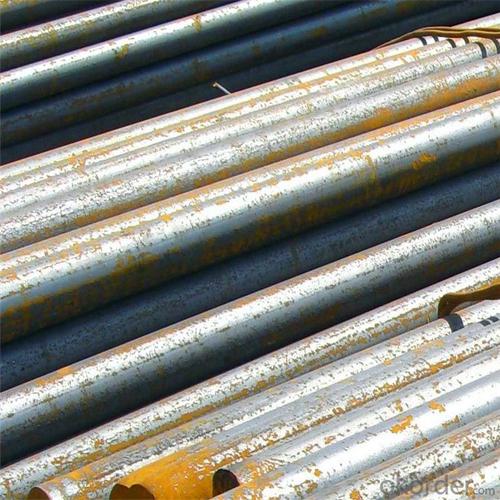

Photo Show of 4130 30CrMo SCM430 Alloy Structure Steel Round Bar

Packing and Delivery:

Packing in bundle package, or as customer's requirements.

Delivery Detail: 45 days after receiving the deposit.

Usage and Applications of 4130 30CrMo SCM430 Alloy Structure Steel Round Bar

1. Steel round bar is used in a large number of architectural and engineering structures. Or it can be used in construction of plants for the production of steel house frames, high-voltage transmission towers, bridges, vehicles, boilers, containers, ships, etc.

2. And we can use this kind of product on the performance of the mechanical parts if the demand is not very high.

3. Some special material steel round bar can be used for main shaft of steamer, hummer shank, with big section and supper force.

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the advantages of using nickel-manganese alloy steel round bars?

- Nickel-manganese alloy steel round bars provide numerous benefits in various applications. To begin with, these round bars exhibit exceptional strength and toughness. The incorporation of nickel and manganese significantly enhances the overall strength and durability of the steel, rendering it suitable for heavy-duty applications that demand high strength and resistance to wear and tear. As a result, industries such as construction, automotive, and manufacturing find these alloy steel round bars highly advantageous. Additionally, nickel-manganese alloy steel round bars possess outstanding corrosion resistance properties. The nickel content in the alloy imparts remarkable resistance to corrosion, making it ideal for use in harsh environments or situations where exposure to corrosive substances is common. Consequently, the lifespan of these round bars is extended, reducing the need for frequent maintenance or replacement. Moreover, these round bars demonstrate excellent heat resistance. They can withstand elevated temperatures without compromising their structural integrity, making them suitable for applications involving extreme heat or thermal cycles. Industries like aerospace, power generation, and oil and gas greatly benefit from this heat resistance property. Furthermore, nickel-manganese alloy steel round bars offer favorable weldability and machinability. The composition of the alloy facilitates easy welding and machining, allowing manufacturers to fabricate components or structures with ease. This versatility in processing makes the round bars highly adaptable to varying manufacturing processes and requirements. Moreover, these round bars exhibit good ductility and formability. The alloy's composition permits easy shaping or forming into various configurations without sacrificing its structural integrity. Consequently, they are suitable for applications that necessitate complex shapes or intricate designs. In conclusion, the advantages of utilizing nickel-manganese alloy steel round bars encompass exceptional strength, corrosion resistance, heat resistance, weldability, machinability, and formability. These properties make these round bars a dependable and versatile choice for a broad range of applications across different industries.

- Q: Can steel round bars be used in the manufacturing of consumer goods?

- Consumer goods manufacturing can make use of steel round bars. Steel is a durable and versatile material that finds wide application across industries, including the production of consumer goods. Steel round bars can be molded, cut, and shaped into various components or parts that are required for items like furniture, appliances, tools, and machinery. The strength and resilience of steel make it a perfect choice for consumer goods that demand robust and long-lasting materials. Moreover, steel can be easily customized and finished with coatings or treatments to enhance its appearance or protect it from corrosion, thereby making it even more suitable for use in consumer goods. In summary, the usage of steel round bars is common in consumer goods manufacturing due to their dependable nature, versatility, and ability to provide the desired quality and functionality.

- Q: Can steel round bars be used in the hydraulic industry?

- Yes, steel round bars can be used in the hydraulic industry. Steel round bars are known for their strength, durability, and resistance to corrosion, making them suitable for various applications in the hydraulic industry. They can be used to manufacture hydraulic cylinders, pistons, and other components that require high tensile strength and reliability. Additionally, steel round bars can be machined and shaped into various sizes and specifications to meet the specific needs of hydraulic systems. Overall, steel round bars are a popular choice for the hydraulic industry due to their excellent mechanical properties and versatility.

- Q: What is the difference between a turned and a polished steel round bar?

- A turned steel round bar and a polished steel round bar both undergo separate processes that result in different surface finishes and properties. A turned steel round bar is typically created by using a lathe machine to remove material from the surface of a steel bar. This process involves rotating the bar against a cutting tool, which cuts away the outer layer and leaves behind a smooth and cylindrical surface. The turned bar may have visible machining marks due to the cutting process, although it is generally considered to have a more precise and uniform diameter compared to other types of steel bars. Turned bars are often used in applications where dimensional accuracy is crucial, such as in machinery or tooling. On the other hand, a polished steel round bar undergoes a different process that involves grinding or buffing the surface to achieve a smooth and reflective finish. Polishing removes any imperfections or roughness from the surface of the steel bar, resulting in a highly lustrous appearance. Polished bars are often used in decorative applications or where visual aesthetics are important, such as in architectural designs or high-end consumer products. In summary, the main difference between a turned and a polished steel round bar lies in their respective manufacturing processes and resulting surface finishes. A turned bar is machined to achieve precise dimensions, while a polished bar is subjected to a polishing process to obtain a smooth and reflective surface. The choice between the two depends on the specific requirements of the application, with turned bars being preferred for dimensional accuracy and polished bars for aesthetic appeal.

- Q: How are steel round bars used in the automotive industry?

- Steel round bars are commonly used in the automotive industry for various applications such as manufacturing of axles, drive shafts, suspension components, and steering systems. These bars provide high strength and durability, allowing them to withstand the heavy loads and harsh operating conditions of vehicles. Additionally, steel round bars can be machined and formed into desired shapes, making them versatile and suitable for different automotive parts.

- Q: Can steel round bars be used for valve stem applications?

- Steel round bars can indeed be utilized for valve stem applications. Their exceptional strength and durability make them a popular choice in numerous industrial settings. In valve stem applications, steel round bars are frequently employed to offer stability and structural support to the valve stem, thus guaranteeing seamless operation and enduring performance. Moreover, steel round bars can be effortlessly machined and fabricated to meet precise specifications, rendering them an adaptable option for valve stem applications.

- Q: Can steel round bars be welded to other materials?

- Other materials can indeed be joined with steel round bars through welding. Welding is a widely used technique for merging various materials, including steel round bars, aluminum, stainless steel, and even non-metallic substances like plastics. However, it is vital to emphasize that successful welding depends on the compatibility of the materials being joined. To ensure a robust and long-lasting bond between the steel round bar and the other material, the welding process necessitates the use of appropriate techniques, filler metals, and sometimes pre-heating or post-weld heat treatment. Moreover, it is important to consider the specific application and the desired properties of the joint in order to determine the most suitable welding method and materials.

- Q: How are steel round bars used in the construction of bridges and buildings?

- Steel round bars are widely used in the construction of bridges and buildings due to their strength, durability, and versatility. These bars are typically made of carbon steel and have a circular cross-section, making them perfect for structural applications. In bridge construction, steel round bars are commonly used for reinforcing concrete structures. They are often embedded within concrete beams, columns, and slabs to enhance their load-bearing capacity and resist bending and shearing forces. The bars are placed strategically in the concrete to provide tensile strength, which complements the compressive strength of the concrete. This reinforcement ensures that the bridge can withstand heavy loads and traffic while maintaining its structural integrity. Similarly, in building construction, steel round bars play a crucial role in reinforcing concrete structures. They are commonly used in the construction of columns, beams, and foundations to increase their load-carrying capacity and prevent structural failure. The bars are typically added to the concrete during the pouring process, forming a sturdy framework that enhances the building's strength and stability. Moreover, steel round bars are also used to create steel frames in the construction of buildings. These frames provide the skeletal structure of the building and support the weight of the floors, walls, and roofs. Steel round bars, due to their high strength-to-weight ratio, are ideal for creating lightweight yet robust frames that can withstand various loads, including wind and seismic forces. Additionally, steel round bars are used for other purposes in construction, such as the fabrication of steel reinforcements, connectors, and fasteners. They can be welded, bolted, or threaded to join different structural elements together, ensuring a secure and sturdy construction. Overall, steel round bars are an essential component in the construction of bridges and buildings. They provide the necessary strength, durability, and flexibility required to create structurally sound and long-lasting structures.

- Q: What are the standard sizes of steel round bars?

- The sizes of steel round bars can vary depending on the country and specific industry standards. Typically, these bars come in a wide range of diameters, starting from 6mm (0.24 inches) and going up to 400mm (15.75 inches) or even larger. For commercial purposes, commonly used sizes include 10mm (0.39 inches), 12mm (0.47 inches), 16mm (0.63 inches), 20mm (0.79 inches), 25mm (0.98 inches), and 32mm (1.26 inches). However, it's important to note that these sizes may differ in various regions and industries. Additionally, specialized applications may require unique dimensions. Therefore, it's always advisable to refer to the relevant industry standards or consult with suppliers to determine the specific standard sizes for steel round bars in a particular context.

- Q: What are the advantages of using structural steel round bars?

- There are several advantages of using structural steel round bars. Firstly, they provide excellent strength and durability, making them suitable for various structural applications. Additionally, their round shape allows for easy fabrication and installation, reducing construction time and costs. Steel round bars also have a high resistance to corrosion and can withstand extreme weather conditions. Moreover, they offer versatility in design as they can be easily bent, shaped, and welded to meet specific project requirements. Lastly, steel round bars are widely available and can be recycled, making them a sustainable choice for construction projects.

Send your message to us

4130 30CrMo SCM430 Alloy Structure Steel Round Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords