400mm HP Grade Graphite Electrode for Sale for Foundry Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Graphite Electrode Description

We has complete production lines, which include raw material mixing, forming line, baking line, impregnation equipment, graphitization line and machining and shaping line. Our annual capacity is 60,0000tons.

2.Main Features of the Graphite Electrode

(1) Direct manufacturer, office based on Beijing.

(2) Competitive price with prior quality

(3) High density with low resistivity

(4) High carbon content

(5) RP HD HP UHP Grade for your reference

3.Graphite Electrode Images

Packaging: Wooden Pallets, well packaged.

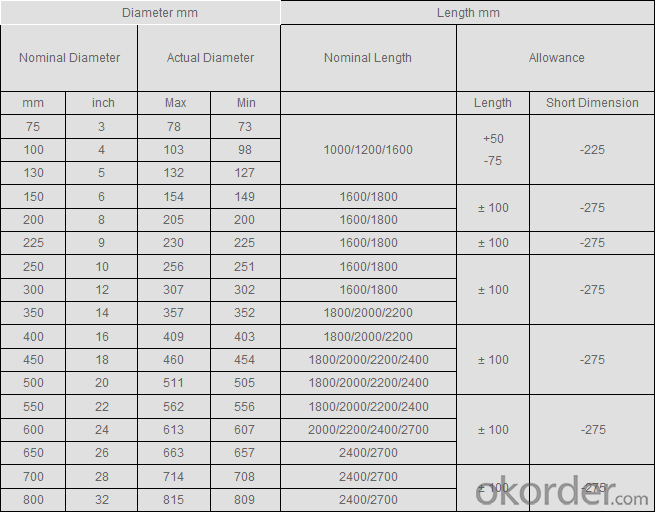

4.Graphite Electrode Specification

5.FAQ

(1) How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; we resolutely put an end to unqualified products material flowing into the market. At the same time, we will provide necessary follow-up service assurance. We welcome you to visit our mill.

(2) MOQ

For trial order, we accept 20 MT.

(3) Payment term

20% deposit, balance against the BL copy。

(4) How long can we receive the product after purchase?

We have large quantity in stock, and we could machine it to the size you need, so the delivery time is around 25 days after receiving your deposit.

- Q: Will the brush grease not short-circuit the commutator?

- The brush of motor is usually made of pure graphite electrode, electrochemical graphite electrode and metal fossil ink electrode material. Because it contains graphite, it has conductive effect on the one hand

- Q: What is the role of the Pt electrode? What is the difference between the graphite electrode and the graphite electrode?

- Carbon electrodes, however, are less likely to be less controllable because of their microstructure, or have some effect on the electric field, if they are sensitive signals

- Q: What are the structures of pyrolytic graphite electrodes? What are their properties and applications? We hope that some details will not be found

- The high purity graphite component is put into the furnace, and nitrogen and methane are produced under vacuum high temperature. Then graphite is shown to produce 10% coating.

- Q: The original battery is not necessary to form the electrode potential? Why can we use graphite as electrode only? No potential difference.

- A galvanic cell is a device that converts chemical energy into electrical energy. Electron transfer not by oxidizing and reducing agents to complete the effective collision between, but the reducing agent loss electron oxidation reaction occurs in the anode, the electron transport to the anode through the external circuit, the oxidant to the anode electron reduction reaction, so as to complete the transfer of reductant and oxidant electrons.

- Q: Which department in the steel plant needs graphite in large quantities?

- The variety and specifications of graphite electrodes used in modern EAF steelmaking are mainly determined by the technical parameters of the steelmaking furnace. With the development of EAF steelmaking technology, the steel-making technology is developing towards large scale and ultra high power. The graphite electrode is mainly made of large size graphite electrode and ultra high power graphite electrode.

- Q: What are the losses in graphite electrode?

- In what environment is the loss, friction, or in the case of high temperature, high temperature will be oxidized, and if in the case of friction, you can first use more wear-resistant graphite material. So please ask this question clearly, and then answer you, thank you.

- Q: Do electroplating experiments, graphite as an electrode, graphite how to pre process to ensure that the coating will not fall, resulting in increased color of the solution

- Graphite as anode, generally do not need special treatment, but to choose high purity, high density, high strength (so-called "three high" graphite) graphite on the line, this graphite in brush plating operations are often used as anode material.

- Q: Graphite electrode press device

- High power graphite electrodes. Graphite electrodes with a current density of 18 ~ 25A / cm 2 are allowed. They are mainly used in high power arc furnaces for steelmaking

- Q: What kinds of carbon are there?

- Graphite electrode class can be divided into ordinary power graphite electrode according to the allowable current density. High power electrode and ultra high power electrode.

- Q: I used 12V direct current, graphite electrode electrolysis sodium sulfide solution, the anode produced a large number of black material, this is why ah?

- Is this principle. Graphite is a layer, each layer, each carbon is SP2 hybrid, and around three carbon connected, finally, between layer and layer formed delocalized covalent bond, making layer and layer can be connected. However, the delocalized covalent bond is not very stable, in attracting Yang Jizheng charge, delocalized covalent bond will certain destruction, the force between the graphite layer and the layer becomes small or not, so as to open.The black stuff is graphite

Send your message to us

400mm HP Grade Graphite Electrode for Sale for Foundry Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches