32 Plastic Nursery Tray & Lids Plastic Nursery Seed Plug Trays for Propagation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

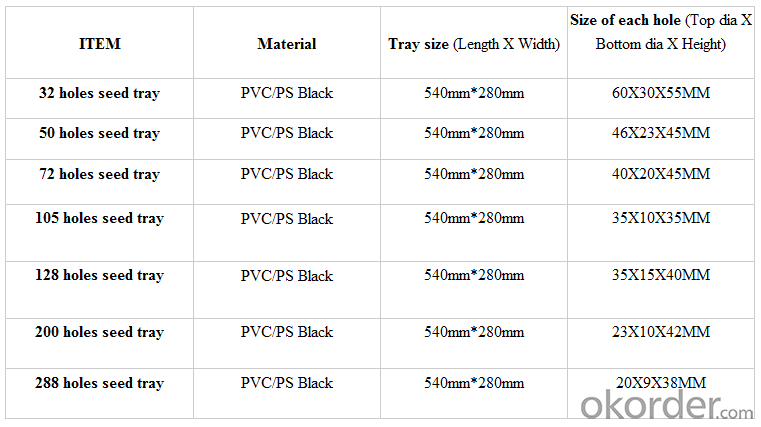

Specification of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

Features of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

· Material: HIPS

· Thickness: 0.5mm-1.5mm, Standard:1mm

· Weight: 80g(±5)g-230g(±5)g, Standard weight:155g(±5)g

· Size: length:490mm-540mm, width:190mm-345mm,depth:25mm-150mm

· Standard:540mmX280mm

· Cell count: 18-512

· Package: In Carton

· Warrenty: 8-10 times

Packaging & Delivery

Packing Detail: export standard carton or large bags

Delivery time: 4 million per momth after receipt of deposit

Advantage:

Waterproof, UV-resistant, extrusion-resistant

Easy carry for young seeding plant and grow

Service:

1. Quick, efficient and professional response within 24 hours, 14 hours online services

2. 10 years manufacturing and exporting experience in agriculture field.

3. Technical support and solution by chief engineer.

4. Strict quality control system & team, high reputation in the market.

5. Full range of irrigation products for choice

6. OEM/ODM services

7. Accept sample order before Mass Order

Picture of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

FAQ of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

Q: 1.How long is the production time?

A: Usually one to two weeks.

Q: 2.How is the seed tray being packaged?

A: They can be packaged in carton or pallets. Carton size is 1375px*725px*1250px.

Q:3.How many times can the seed tray be used?

A: Under the same environment, it is decided by the thickness. Usually 0.6mm thickness can be used for 1 or 2 times.

1.0 thickness can be used for 3-4 times. 1.5 thickness can be used for 8-10 times.

- Q: How does ground cover affect the overall microclimate of a garden?

- Ground cover plays a crucial role in shaping the microclimate of a garden. It helps regulate temperature by reducing heat absorption from the sun, preventing excessive evaporation, and providing insulation during colder periods. Ground cover also retains moisture in the soil, reducing water loss through evaporation and creating a more humid microclimate. Additionally, it acts as a barrier against wind, reducing wind speeds and creating a more sheltered environment. Overall, the right choice of ground cover can significantly impact the microclimate of a garden, influencing temperature, moisture levels, and wind conditions.

- Q: i live in Las Vegas and i cracked my plastics on my Kawasaki kfx700 anybody have some cheap ones for sale

- Dont okorder There is a used parts section in it for every atv imaginable. Someone may have something for you. Also, if it isnt a bad crack, I always drilled small holes on each side of the crack, and zip tied it together pretty tight. I raced some races with it like that, and never had one problem.

- Q: What is the cost of agricultural plastic products?

- The cost of agricultural plastic products can vary depending on factors such as the type of product, quantity needed, and the supplier. It is best to contact specific suppliers or check online platforms to get accurate and up-to-date pricing information.

- Q: How do agricultural plastic products assist in controlled release of fertilizers?

- Agricultural plastic products, such as mulch films and nutrient delivery systems, play a crucial role in the controlled release of fertilizers. These plastic materials are designed to slowly release the fertilizers into the soil over an extended period. The mulch films create a barrier between the soil and the atmosphere, preventing the rapid evaporation of water and the escape of nutrients. This allows for more efficient utilization of fertilizers by the plants as they can absorb them gradually, reducing the risk of leaching or nutrient loss. Additionally, nutrient delivery systems, such as plastic-coated fertilizers or slow-release capsules, provide a controlled and sustained release of nutrients, ensuring that plants receive a continuous supply of essential elements for their growth and development. Overall, agricultural plastic products assist in maintaining a balanced nutrient supply, improving crop yield, and reducing environmental impacts.

- Q: Can ground cover plants be used to cover bare patches in gravel driveways?

- Yes, ground cover plants can be used to cover bare patches in gravel driveways. They not only enhance the aesthetics of the driveway but also help prevent erosion and control weed growth. Additionally, ground cover plants can improve soil stability and reduce dust. It's important to choose low-growing and hardy varieties that can tolerate the conditions of a gravel driveway, such as drought tolerance and being able to withstand vehicle traffic.

- Q: How do agricultural plastic products aid in soil erosion prevention?

- Agricultural plastic products aid in soil erosion prevention by acting as a protective barrier on the soil surface. They help to reduce the impact of rainwater, wind, and other natural forces that can dislodge the topsoil and cause erosion. The plastic products, such as mulch films or geotextiles, effectively control water runoff, retain moisture, and stabilize the soil, thus minimizing erosion and promoting healthier crop growth.

- Q: What are the advantages of using plastic compost bins for organic waste management?

- There are several advantages of using plastic compost bins for organic waste management. Firstly, plastic compost bins are lightweight and portable, making them easy to move around and position in a convenient location. Additionally, plastic bins are durable and weather-resistant, ensuring they can withstand various environmental conditions. Moreover, plastic does not absorb moisture, preventing any potential leakage or odors. Plastic compost bins also have good insulation properties, helping to maintain optimal temperatures for decomposition. Lastly, plastic bins are easy to clean and maintain, allowing for efficient and hassle-free composting.

- Q: This question seeks to understand the positive economic impacts of utilizing biodegradable plastic products in agriculture.

- <p>The economic benefits of using biodegradable agricultural plastic products include reduced environmental cleanup costs, as these products break down naturally, avoiding the expenses associated with removing traditional plastics. They can also lead to cost savings in the long run by improving soil health, which enhances crop yields and reduces the need for chemical fertilizers. Additionally, biodegradable plastics can lower energy consumption and greenhouse gas emissions in the production process, which may result in financial incentives or subsidies in regions with environmental policies. Furthermore, they can create new market opportunities for agricultural businesses that adopt sustainable practices, potentially increasing their competitiveness and profitability.</p>

- Q: How long does it take for ground cover plants to establish and spread?

- The time it takes for ground cover plants to establish and spread can vary depending on a variety of factors such as the specific type of plant, environmental conditions, and maintenance practices. However, on average, ground cover plants typically take around 1 to 3 growing seasons to establish and spread adequately.

- Q: Are nursery trays suitable for growing aquatic shrubs?

- No, nursery trays are not suitable for growing aquatic shrubs as they are designed for terrestrial plants and lack the necessary features for water retention and drainage needed by aquatic shrubs.

Send your message to us

32 Plastic Nursery Tray & Lids Plastic Nursery Seed Plug Trays for Propagation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords