32 Plastic Nursery Tray&Lids Plastic Nursery Seed Plug Trays for Propagation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

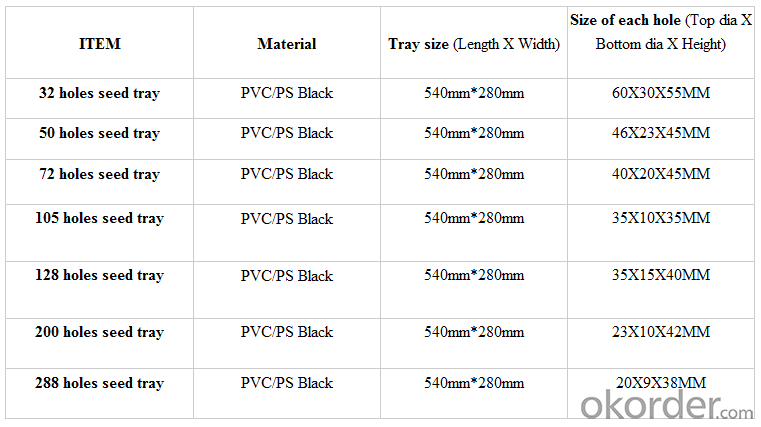

Specification of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

Features of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

· Material: HIPS

· Thickness: 0.5mm-1.5mm, Standard:1mm

· Weight: 80g(±5)g-230g(±5)g, Standard weight:155g(±5)g

· Size: length:490mm-540mm, width:190mm-345mm,depth:25mm-150mm

· Standard:540mmX280mm

· Cell count: 18-512

· Package: In Carton

· Warrenty: 8-10 times

Packaging & Delivery

Packing Detail: export standard carton or large bags

Delivery time: 4 million per momth after receipt of deposit

Advantage:

Waterproof, UV-resistant, extrusion-resistant

Easy carry for young seeding plant and grow

Service:

1. Quick, efficient and professional response within 24 hours, 14 hours online services

2. 10 years manufacturing and exporting experience in agriculture field.

3. Technical support and solution by chief engineer.

4. Strict quality control system & team, high reputation in the market.

5. Full range of irrigation products for choice

6. OEM/ODM services

7. Accept sample order before Mass Order

Picture of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

FAQ of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

Q: 1.How long is the production time?

A: Usually one to two weeks.

Q: 2.How is the seed tray being packaged?

A: They can be packaged in carton or pallets. Carton size is 1375px*725px*1250px.

Q:3.How many times can the seed tray be used?

A: Under the same environment, it is decided by the thickness. Usually 0.6mm thickness can be used for 1 or 2 times.

1.0 thickness can be used for 3-4 times. 1.5 thickness can be used for 8-10 times.

- Q: What are the different types of silage covers available?

- There are several different types of silage covers available, including oxygen barrier films, multi-layered plastic covers, tarpaulins, and oxygen-limiting bags.

- Q: what are the advantages of paper against plastic.

- Plastics are produced from the waste products of oil refining. There are environmental impacts associated with the extraction of oil, the separation of products in the refining process, and the manufacturing of plastics. Paper is produced from trees; environmental impacts include those associated with extracting timber and processing it for paper products. Again, the environmental impacts depend on whether the timber was obtained from a sustainably managed forest -- most industrial timber products in the U.S. come from plantations -- and the environmental management of the paper processing plant. Comparatively, plastic bags require less energy to produce. The disposal of bags entails additional environmental impacts. If landfilled, plastic bags are more environmentally benign than paper, as they require less space; paper occupies approximately half of overall landfill volume. Plastics do not biodegrade. Stray plastic bags, which have been estimated at one to three percent of the hundreds of billions that are produced each year, are now found almost everywhere on the planet. Plastic bags pose a threat to marine life, because, if ingested, the bags can block the stomach and cause starvation. Sea turtles, for example, mistake plastic bags for jellyfish. In 2002 a minke whale that washed up on a beach at Normandy was found to have 800 grams of plastic and other packaging in its stomach. Stray plastic bags can also clog sewer pipes, leading to stagnant, standing water and associated health hazards. In 2002, Bangladesh banned plastic bags after drains blocked by bags contributed to widespread monsoon flooding in 1988 and 1998. Ireland has decreased plastic bag consumption by placing a consumer tax on plastic bags. Perhaps the most strict plastic bag regulations are found in the Indian province of Himachal Pradesh, where people caught with plastic bags are fined $2000.

- Q: Can ground cover be used to create a water-wise garden?

- Yes, ground cover can be used to create a water-wise garden. Ground cover plants help to reduce water evaporation, suppress weed growth, and retain moisture in the soil, thereby minimizing the need for frequent watering. Additionally, ground cover plants often have deep root systems that can access water deeper in the soil, making them more drought-tolerant. Choosing water-efficient ground cover species, such as succulents or native plants, can further enhance the water-wise nature of the garden.

- Q: Can ground cover plants help improve soil quality?

- Yes, ground cover plants can help improve soil quality. They play a crucial role in preventing soil erosion, conserving moisture, and suppressing weed growth. Additionally, their root systems help aerate the soil, enhancing its structure and nutrient availability. As ground cover plants decompose, they contribute organic matter to the soil, improving its fertility and overall quality.

- Q: Can nursery trays be used for starting annual vegetable transplants?

- Yes, nursery trays can be used for starting annual vegetable transplants.

- Q: How do you fix a crack in a plastic bumper cover?

- you can also purchase the plastic welder and materials at any harbour freight tool store inexpensively.

- Q: Can ground cover be used to create a natural-looking rock garden?

- Yes, ground cover can be effectively used to create a natural-looking rock garden. Ground cover plants such as creeping thyme, mosses, sedums, or creeping phlox can be interspersed between the rocks, softening the edges and providing a lush and natural appearance. These plants also help suppress weeds, retain moisture, and create a harmonious blend between the rocks and surrounding landscape.

- Q: What is the best ground cover for a desert garden?

- The best ground cover for a desert garden would be drought-tolerant plants such as succulents, cacti, or native desert grasses. These plants require minimal water and can withstand the harsh conditions of a desert environment.

- Q: How do nursery trays assist in maintaining proper soil moisture levels?

- Nursery trays assist in maintaining proper soil moisture levels by providing a controlled environment for plants to grow. These trays are designed with drainage holes that allow excess water to escape, preventing waterlogging and ensuring adequate drainage. Additionally, the trays help retain moisture in the soil by reducing evaporation, thus keeping the soil consistently moist for optimal plant growth.

- Q: what is forex plastic i have searched the internet thnks

- It looks like it is a brandname for a specific signage material - FOREX classic is an expanded rigid plastic sheet with a particularly fine and homogenous cell structure and silky matt surfaces. FOREX°classic is lightweight ?FOREX°classic has silky mat surfaces ?FOREX°classic has a closed homogeneous cell structure ?FOREX°classic is difficult to ignite and self-extinguishing (B1, M1, Cl.1)

Send your message to us

32 Plastic Nursery Tray&Lids Plastic Nursery Seed Plug Trays for Propagation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords