304 Cold Rolled Stainless Steel for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:304/304L/316/316L/321/409/409L/410/410S/430

Type:Stainless Steel Strips

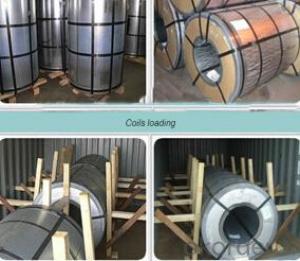

Shape:Coil

Grade:300 Series

Certification:ISO, SGS

Perforated:Not Perforated

Standard:ASTM, AISI, GB, JIS, DIN, EN

Technique:Cold Rolled

Surface Treatment:Bright

Surface:2D,2e,2b,2bb,Sb,No.4,Ba,Hl,6k,7k,8k

Width:1000mm/1219mm/1250mm/1500mm/1524mm/1829mm/2000mm

Thinckness:0.3mm to 6mm

Edge:Silt/Mill Edge

Export Markets:Global

Product Description

The detail specification of cold rolled stainless steel coils are as below:

| Grade: | 201/202/301/304/304L/316/316L/317L/321/409/409L/410/410S/430/439 |

| Standard: | ASTM,AISI,JIS,EN,DIN,GB |

| Surface: | 2D,2E,2B,2BB,SB,NO.4,BA,HL,6K,7K,8K |

| Width: | 1000mm/1219mm/1250mm/1500mm/1524mm/1829mm/2000mm |

| Thickness: | 0.3mm to 6mm |

| Edge: | Slit/Mill Edge |

| Origin: | TISCO,POSCO,LISCO,JISCO,BAOSTEEL,Baoxin,Eastern Special Steel and so on |

| Productivity: | 10000MT/Mont |

| MOQ: | 30mont |

| Payment Term: | TT,L/C at sight/, L/C 30,60,90,180 days,WEST UNION |

| Price Term: | FOB/CFR/CIF Ningbo,Shanghai,Tianjin,Shenzhen Port |

| Delivery: | 7-10 days after receive buyer's advance deposit or LC copy |

| Packaging: | Seaworthy Export Standard Package.Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might otherwise be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information. |

| Detail Application: | construction field;ship building industry;petroleum and chemical industries;war and electricity industries;food processing and medical industry; boiler heat exchanger; machinery and hardware industry |

Technical notes:

| Surface Finish | Definition | Application |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

| 2D | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment. | Construction Material, heat exchanger,exhaust pipe |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| No.8 | A highly reflective finish obtained by polishing with successively finer abrasive and buffing extensively free of grit lines | Indoor decoration & Reflector, Hospital Equipment |

Our Advantages

All products are made of high-quality imported raw materials.

Excellent shipment after-sales service & Prompt

The Authorized agent of TISCO,JIISCO,the stainless steel distributor of BOSTEEL,ZPSS,LISCO and also can get the resources from all the stainless steel mills in China.

Have own processing and distribution center & can take the orders according to customers' requirements.

The transport in Hangzhou is very convenient & nearby Shanghai and Ningbo Port.

Our products are certified by ISO9001:2008 authentication quality systems.

Quick Response to Your Enquiry.

- Q: which one(glass or steel)has more power and velocity? im planning on using my slingshot for hunting.

- definitely steel. i used to hit bullseyes with a good slingshot, and you need heavy, perfectly spherical small steel shot. smaller than a marble, bigger than a bb.

- Q: I've heard on some 1911 forums that the slides of Armscor guns are now extruded. What is extruded steel? How is it made? Are they strong (4140carbon steel was used in the process).

- Extruded steel is only the steel being run through a die when it is heated, it usually reduces the size of the grain of the steel itself, enhancing toughness. Realistically though, in a handgun, it doesn't matter if the frame is cast or forged, both types will hold up to any amount of abuse, unless you use it as a sledgehammer, and are splitting stones with it, then the forged frame would win. 4140 is more than adequate for a slide/frame. Hell, even mild steel would be adequate as long as you don't mind some dings and scratches, and again, don't use it as a sledgehammer...

- Q: I'm trying to buy a Survival,tactical knife but don't know what steel is better

- Vanadium Steel Knives

- Q: Can steel coils be coated with tin?

- Yes, steel coils can be coated with tin through a process called tinplating. Tinplating provides corrosion resistance and enhances the appearance of the steel surface.

- Q: and is that different from the components of steel

- Making steel is very energy intensive. Mining the raw ore requires a lot of machinery that uses fuel or electricity . Transporting the ore requires a lot of fuel. Refining not only uses a lot of electricity but coal is added to change the iron ore into steel.

- Q: I feel really stupid asking this question but i feel like a put metal/steel strings on my classical guitar how do you tell the difference?

- you do NOT want to put steel strings on a nylon string guitar, it will ruin it. It does get a little confusing. With steel strings, all 6 strings are metal. (usually steel, but not always, nickel, copper may be used too) And they use a steel core. with nylon strings, the high 3 strings, are obviously nylon/plastic. the 3 bass strings look metal, but they have a silk type core, with metal wrapped around it. The steel strings have a LOT more tension,, they can break the plastic tuners, beak the nut, pull the top up, and pull the bridge off, If you're not sure yet, have a real music store explain it, not a toy store, or costco or walmart.

- Q: Can steel coils be coated with anti-tampering materials?

- Yes, steel coils can be coated with anti-tampering materials. These materials are commonly applied to steel coils to prevent unauthorized access or tampering, ensuring the integrity and security of the contents within the coils.

- Q: Hello. right now i have been playing electric and acoustic guitar for 6 years. I currently became very interested in learning the pedal steel guitar. I will be teaching myself so is it really hard to learn? Are there a lot of songs online that could give me tabs? Basically im asking if it is worthwhile to spend a lot of money. I dont want it if there are only 3 songs im gona learn. im up for the challenge im just curious how hard it was to learn. thanks for your help.

- The okorder /... Beware of eBay deals unless you know what you're buying. To start, you should get a 10-string single neck with 3 pedals and 4 levers. Some of the student models don't have as many levers and aren't capable of all the changes you need. Stay away from the ShoBud Maverick...you'll outgrow it in a couple of months. Often it makes more sense to buy a used professional model...you'll eventually need one, and they hold their value better than a student model. You'll also need a volume pedal, bar, thumb and finger picks. For now, your guitar amp will be ok. Playing the guitar: There are several tunings and lots of different combinations of levers, but the basic guitar is a 10 string E9 tuning. It's almost an open E but with a few extra notes. The pedals and levers raise and lower the pitch of selected strings. Chord changes are made by moving the bar and pressing pedals and levers. The volume pedal helps you swell and sustain notes. Steel has it's own unique tablature which reflects all these changes. If you have any other questions, feel free to email me or just join the PSG forum and ask there.

- Q: What are the typical lead times for steel coil orders?

- The typical lead times for steel coil orders can vary depending on various factors such as the quantity and specifications of the coils, current market conditions, and the supplier's production capacity. However, lead times commonly range from a few weeks to a couple of months. It is always best to confirm with the specific supplier for accurate and up-to-date lead time information.

- Q: I need new sprockets on my GSX-R1, I've heard that alumnium sprockets wear out twice as fast as steel and the difference is not noticable

- i also have a gsx-r1000 06.. always change the sprockets and chain at the same time if you don't it will just wear out the chain faster. all you really need is to go down 1 on the front sprocket and 2 up on the back. stick with the steel sprockets they will save you money in the long run. if you like to wheelie all the time stay away from the aluminum it will wear out quicker.. they also make sprockets that are aluminum on the inside and steel on the outside.

Send your message to us

304 Cold Rolled Stainless Steel for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords