3.2m Fiberglass FRP gel coat flat panel special for truck body making machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

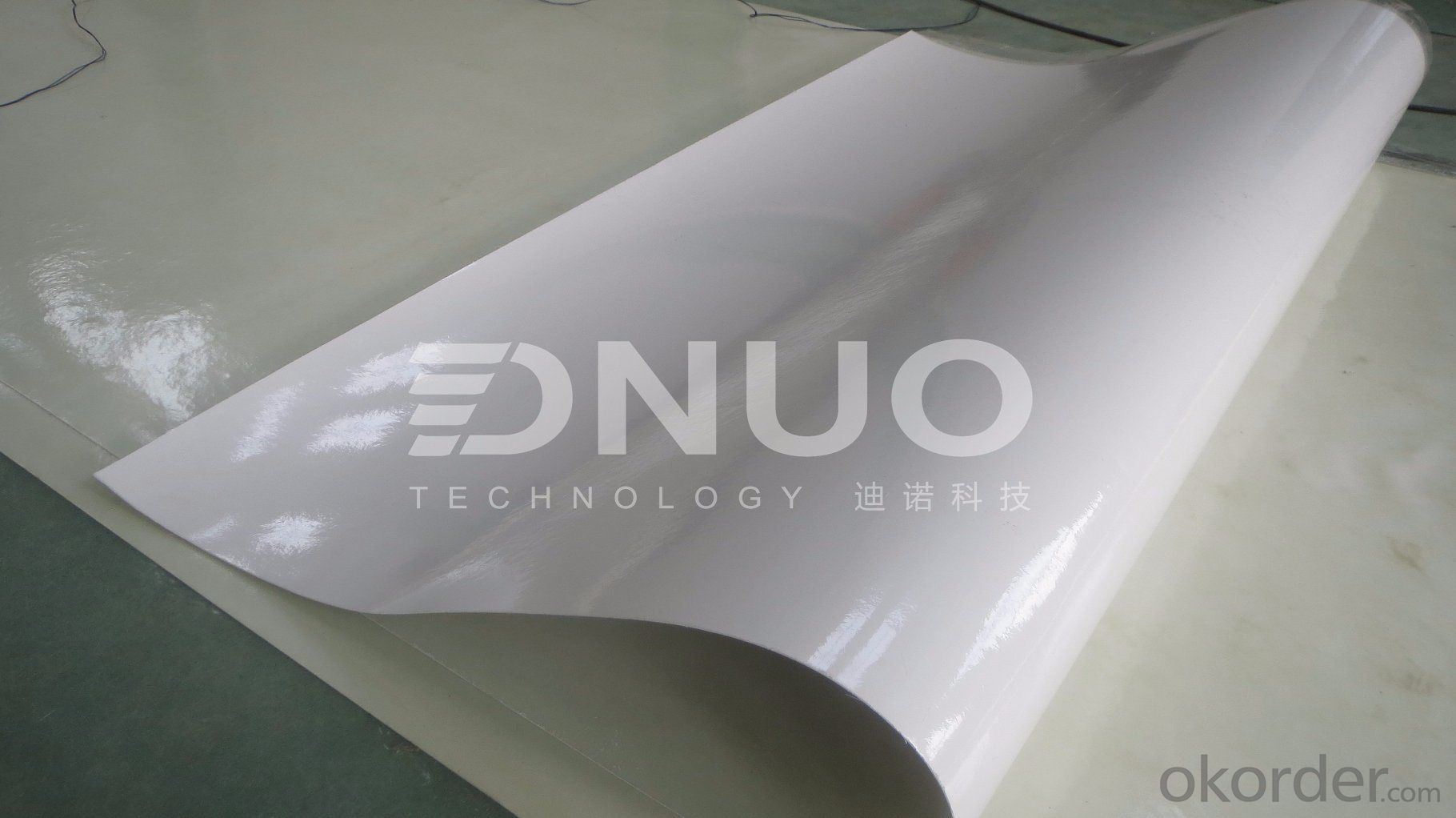

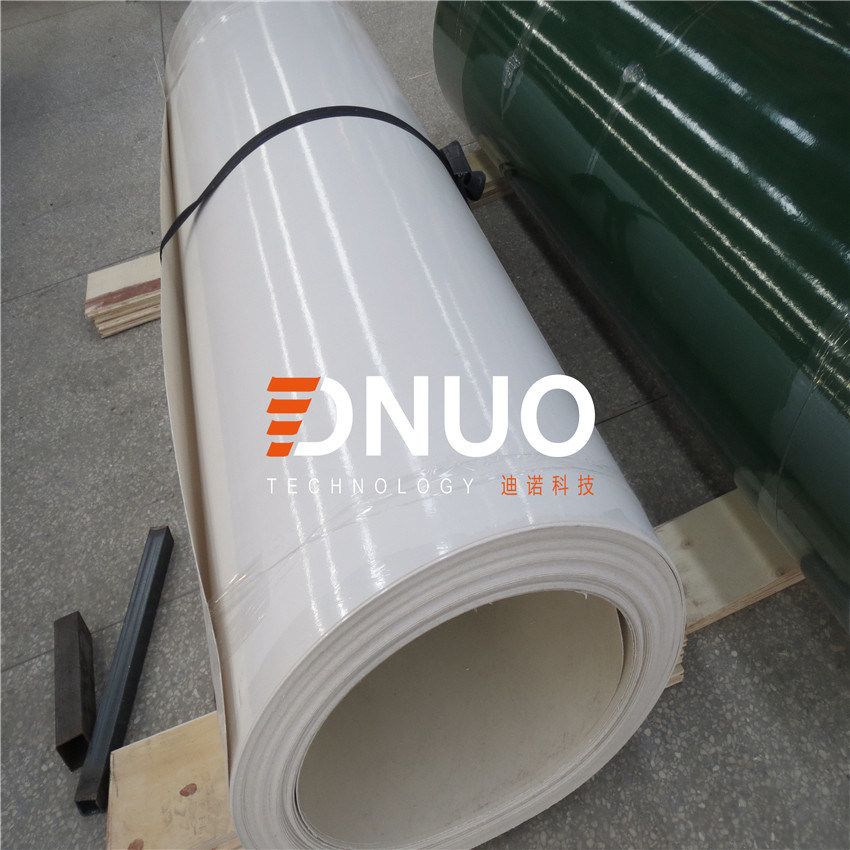

This production line can produce lighting sheet, color sheet, common flat sheet, gel coat sheet.

Products Show

Process production

Machine character

1、 Apply high precision import forging doctor blade, smaller error, Thin & even gel coat coating.

2、 Gel coat curing area apply clip flatten roller designed by Dnuo technology company, easy operation & good tensioning effect.

3、 The impregnation table can control temperature independently & accurately. It can adapt to the outside temperature fast, impregnation fast and improve the production speed effectively.

4、 Pulse free metering system, accurate metering, and wide flow rate adjustment range. It can add powder filler.

5、 Easy operation based on PLC intellectual control system. Operate by two computers, the production task and equipment operating data is faster and intuitional. Only short-term training can make operators complete production independently.

6、 Three separate ovens for temperature control, Unique temperature control arithmetic makes oven heating fast, temperature control precise. Which improve quality of products, reduce energy consumption and shorten the preparing time effectively. This way makes sheets curing better.

7、 Metering control system and Roving chopper speed can be synchronous with the production line.

8、 Special cross cutting machine and good synchronization performance make cutting accurately..

9、 All the machine parts adopt international standard steel make machine with high stability.

10、System failure can be automatically alarmed and show fault point. Make maintenance easily.

11、Particular parts adopt special purpose wire, durable in use.

12、Size and layout of machine can be made according to customer requirements

13、Electric system adopt siemens brand.

Our Factory

We are professional manufacturer of FRP sheet production line. We are the first domestic production of FRP sheet making machine and biggest-selling company. We can provide many types of FRP sheet forming production lines, like FRP lighting sheet production line, FRP gel coat sheet production line, FRP embossed sheet production line and FRP decorative sheet production line etc. Dnuo has occupied more than 60%-70% domestic market with obvious advantage. The product has been exported to the USA, Saudi Arabia, Jordan, India, Indonesia, Malaysia, Vietnam and Azerbaijan etc.

Over the years we have been focusing on the FRP sheet continuous forming techniques. We have successfully provided the professional FRP sheet continuous shape forming equipment to several well-known enterprises domestic and abroad. We provide a perfect solution to enterprises who aim at high efficiency production of high quality FRP sheet.

Exhibition

After sale service

Package

For the large-sized parts, we take some measures to fix them.

For the other parts,we pack them with polywood.

we declare that we will try our best to pack

our goods well make them arrive in destination safely.

Guarantee and After-sale Service

1. Guarantee for 1 year excluding wear and electrical parts. Extra fee is paid if out of date. Any damage to the machine caused by improper use will be charged.

2. The equipment is fully test before delivery

3. Free installation, training and commissioning on site to help the operators operate as soon as possible

4. We will provide wear and electrical parts at an agency price when you need replacement.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory. Certainly if you need other special product, we will do our bestto help you, so we can build a long-term business relationship.

Q: Can I order the product with special size?

A: Of course you can, also we will produce the products according to your detail requests.

Q: Why we are your best choice?

A: We have direct factory and many years of export experience, and offer the best price withhigh quality product, timely delivery, also have good after-sales service, therefore with goodreputation on boards and with many clients have good long-term business relationship.

Q: How many years experience do you have in this industry ?

A: Our factory was established in 1999, thanks for 17 years old development, our design and production team became stronger and stronger.By now we have became the fist large scale enterprise on this field.

- Q: What are the features of plastic injection gears and machined plastic gears?

- Injection of better, smooth finish, smoothness can be done on the mold, the strength is also good. When machining, some of the transmission, the edge may be very difficult to process, very beautiful

- Q: The main plastic of plastic products

- Polyethylene plastics (Polyethylene) are polymers of ethylene monomers. The raw material for production is oil, coke oven gas or alcohol. Industrial production of polyethylene usually by ethanol dehydration, acetylene catalytic hydrogenation or high temperature cracking. Its commodity name is abbreviated as "B plastic"; the English abbreviation is "PE". Because the density of polyethylene is different, it is divided into low-density polyethylene.[PE (L)], medium density polyethylene [PE (M)] and high density polyethylene [PE (H)].The molecular formula of polyethylene is: (- CH2, CH2 -) n. It is linear in geometry and theoretically has no branched chain and is prone to crystallization. Usually the polyethylene molecule is composed of crystalline and amorphous state in high elastic interlaced region; crystalline polyethylene plastic gives high hardness, strength, chemical stability; amorphous region with polyethylene plastic higher flexibility, toughness, transparency etc.. In fact, polyethylene macromolecules are not absolutely free of branched chains. Its crystallinity is different, density is different, physical and mechanical properties are also different.

- Q: I am going to work as a worker in a plastics factory. I wonder if the work inside it is very polluting. Is there any harm to the health?

- If you go to a general plastic factory, there will be no pollution. The recycling factory will be a little bigger. It will be very hot in the hot weather, but it will be better in winter

- Q: Which kind of engineering plastics has good processability?

- Organic glass rods and plates, PTFE rod material, nylon rod, PVC sheet and other mechanical processing performance is good.

- Q: now have no market quite suck me how to go find the market ask predecessors and friends hope that they can point out a way to thank you

- I'm from Guilin, Guangxi.I'm a commodity trading company. How many styles do you have?

- Q: What kind of machinery does a plastic product factory need?

- Processing from waste to products: plastic cleaning machine, plastic crusher and granulator, these three machines processed waste plastics into plastic particles.Then the plastic particles processed into plastic products: mixing machine, film blowing machine, and then add to bag printing film printing machine, the printed plastic bags made in different types of bag making machine, bag making machine, plastic bags of different cold cutbag machine with flat pocket and vest bag, bag making machine only do vest bag. Then, if the garbage bag is a garbage bag with a roll, you must use a winding bag machine, not even roll, one by one according to the maximum width of the bag size cold cutting bag machine.Note: film blowing machine, bag machine, press machine according to the maximum width of your bag to match. The general standard size is: 600mm, 800mm, 1000mm, 1200mm and other models. The bigger the size, the higher the price

- Q: Every time I look for work on the Internet, I am confused. What kind of industry does the plastic belong to?..

- According to the latest "national economic industry classification (GB/T 4754-2011)", the plastic products industry belongs to the C category manufacturing industry, the 29 major categories of rubber and plastic products industry, and the 292 category of plastic products industry.First, manufacturing is interpreted as "this category comprises 13 to 43 categories, refers to the physical or chemical change after a new product, whether it is power machinery manufacturing, or Handmade; and whether the product is sold wholesale or retail, are regarded as a variety of manufactured goods and parts in building production should be as for manufacturing, but in the pre construction site are the main components of products, assembly, warehouse equipment, railway bridges and highway, elevator and elevator, pipeline equipment, water equipment, heating equipment, ventilation equipment and air conditioning equipment, lighting and wiring assembly activities, and building the device are listed for the construction and manufacturing the categories include mechanical and electrical products, the scrap auto parts, engineering machinery, machine tools and other batch production process of professional repair, remanufacturing production Products to achieve the same quality and performance as the new products".

- Q: How much do you need for it? How about the raw material?

- Good investment in fixed assets and capital flow of fixed assets including site fees, workshop and warehouse and other construction costs, equipment investment (the inquiry to equipment manufacturers), capital flows to see your production scale and product sales capital recovery ability. Specific investment, you can find an expert consulting, I do not understand this line.

- Q: tooling mold design, processing, whether the need for quality certification system?

- Management system certification is basically looking at the enterprise's own needs, nor is it mandatory, but if you are here, if useful in the car, you have to do TS certification

- Q: How do we calculate the cost?

- So many people bought equipment and started, most of the friends have just started, mainly chemical fiber bags (PP woven bags) granulation, plastic film granulation, plastic bottles, broken materials, and so on.2, followed by the main problem is the use of equipment:1). Performance of the equipment are not familiar with the problems of using too much, such as temperature control is not good (low price devices do not have automatic temperature control system, through experience), products can not achieve the desired requirements, the color is not good, drawing off a serious, low yield, often blocking filter, cutting unevenness, severe adhesion.2) raw materials sorting is not clear, cleaning is not in place, impurities, broken bar serious, bad color. The same raw materials, the same approach, the product is not as good as others, the price is far from.3), procurement of raw materials, usually all recycled plastic, when you formed a batch production, to ensure the supply of raw materials can not be too much, impurities in raw materials procurement, and even pit you encounter people, buy a home is water, stone bag.4) sales problems: I don't know who sells the products. I don't know what the price is, or even say you have such and such problems.Moreover, the beginning of production, it is impossible to form mass production, small amount of bad sales, because customers need to be generally enough to a car to load, 2T-3T is not good, and more afraid of production, fear of backlog.

Send your message to us

3.2m Fiberglass FRP gel coat flat panel special for truck body making machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches