2mm Cold Rolled Steel Sheet Iron Steel China Suppliers

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

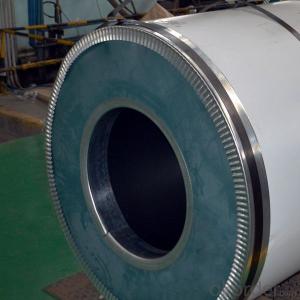

2mm Cold Rolled Steel Sheet Iron Steel China Suppliers

Quick Information

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DC01,SPCC,ST12

Thickness: 0.13~4.00mm

Model Number: DC01,SPCC,ST12

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Oiled, Oiled

Application: Normal Formed Steel for Refrigerator Casing, Oil Drum, Steel Furniture, Refrigerator Casing, Oil Drum, Steel Furniture

Width: 600~1250mm

Length: Any Length Based on Coil Weight or by Required

Product Name: 2mm Cold Rolled Steel Sheet Iron Steel China Suppliers

Key Word: Cold Rolled Steel Sheet

Surface: Bright, Matt

Coil Inner Diameter: 508/610mm

Coil Weight: 3--10MT

Steel Grade: DC01,SPCC,ST12

MOQ: 25MT

Supply Ability: 550,000 MT per year

Specification

Commodity | 2mm Cold Rolled Steel Sheet Iron Steel China Suppliers | |||

Standard | AISI, ASTM, BS, DIN, GB, JIS,etc. | |||

Nominal Thickness | 0.13~4.00mm | |||

Nominal Width | 600~1250mm | |||

Length | Any length based on coil weight or by required | |||

Coil Inner Diameter | 508/610mm | |||

Surface | Bright, Matt | |||

Grade | DC01,SPCC,ST12 | |||

Delivery lead time | 15~30 Days after Receiving T/T Prepayment or LC Date | |||

Price term | FOB,CIF,CFR,EX Works,FCA | |||

Port of Loading | China Port | |||

Payment | L/C at Sight | |||

T/T 30% in Advance,70% Balance against B/L copy | ||||

Supply ability | 550,000 metric tons per year | |||

MOQ | 25 metric tons | |||

Packing | Mill's standard export sea-worthy packing | |||

Application | Normal Formed Steel for Refrigerator Casing, Oil Drum, Steel Furniture etc | |||

Packing and Package

Packing: Mill's standard export sea-worthy packing

MOQ: 25 MT( in one 20ft FCL)

Delivery time: 15-30 days after prepayment or L/C date

Remark: The third party inspection is accepted

Supply Ability

Product category | CR | GI/GL | PPGI/PPGL | Corrugated Steel Sheet | CRNGO |

Production lines | 4 | 4 | 3 | 2 | 1 |

Production capacity(MT/year) | 550000 | 700000 | 450000 | 28000 | 200000 |

Picture

- Q: I'm talking about the sort of carbon fiber that's used in the auto industry (mostly in supercars).If an object made of steel were to be copied by an exact same object, but made of carbon fiber - how lighter would the carbon fiber object be?For example, if a table is made of steel and it weighs X, how much will it weigh if it were made of carbon fiber?Thanks.

- In most applications, you do not want to make the graphite fiber composite object the same size as the steel object. You want it to have the same strength. So... the benefit of using the composite is not just the difference in density. What you really want to compare is the specific strength and you can define this slightly differently depending on your application. As a simple example, suppose you need to hang a weight of 100 pounds from a beam with a bar (so the load is pure tension) and not have the weight permanently stretch the bar (so stress in the bar is less than the yield stress). You can calculate the cross sectional area of steel and compare that to the cross sectional area of the graphite fiber composite required. If your application is more complicated, say it has to support the load and flex up to 10 degrees and survive some impact loading and operate at a max temperature of 200C, then you have more homework to do to select the best material. And... if you are not rich enough so that money is no object, you also need to consider the cost.

- Q: How are steel coils used in the production of steel doors?

- Steel coils are used in the production of steel doors as the primary raw material. These coils are unwound and fed into a roll forming machine, where they are shaped into the desired door profile. The steel coils provide the necessary strength, durability, and rigidity to the doors, ensuring they can withstand various external forces and provide security.

- Q: What are the common methods of joining steel coils together?

- The common methods of joining steel coils together include welding, mechanical fastening (such as using bolts or screws), and adhesive bonding.

- Q: How are steel coils used in the production of automobile frames?

- Steel coils are an essential component in the production of automobile frames. These coils, made from high-quality steel, are first uncoiled and then fed into a stamping press where they are shaped into various parts of the frame. The steel coils provide the necessary strength and rigidity required to support the weight of the vehicle and ensure its structural integrity. Once the coils are stamped into the desired shape, they are often welded together to form the frame structure. This welding process helps to join the individual components securely, ensuring that the frame can withstand the forces and stresses encountered during the vehicle's operation. The use of steel coils in automobile frame production also allows for flexibility in design, as they can be easily shaped and manipulated to meet specific requirements. Furthermore, steel coils offer excellent durability and resistance to corrosion, making them ideal for automotive applications. The frames produced using these coils are strong, reliable, and able to withstand harsh conditions and road vibrations. This not only enhances the safety of the vehicle but also contributes to its longevity and overall performance. In addition to automobile frames, steel coils are also used in other critical components of the vehicle, such as suspension systems, chassis, and body panels. Their versatility, strength, and cost-effectiveness make them a preferred choice in the automotive industry. Overall, the utilization of steel coils in automobile frame production plays a significant role in ensuring the safety, durability, and performance of modern vehicles.

- Q: How are steel coils used in the production of electrical equipment?

- Steel coils are used in the production of electrical equipment as they serve as the core material for various components, such as transformers and inductors. The magnetic properties of steel make it ideal for creating a magnetic field, allowing for efficient energy transfer and voltage regulation. By winding the electrical wires around the steel coils, the magnetic field can be generated, enabling the proper functioning of electrical devices and equipment.

- Q: What are the applications of stainless steel coils?

- Stainless steel coils have a wide range of applications across various industries due to their unique properties and characteristics. Some of the key applications of stainless steel coils include: 1. Manufacturing industry: Stainless steel coils are extensively used in the manufacturing sector for the production of various products such as automotive parts, kitchen appliances, machinery components, and construction materials. The high corrosion resistance and durability of stainless steel make it an ideal choice for these applications. 2. Construction industry: Stainless steel coils are widely used in the construction industry for applications such as roofing, cladding, structural supports, and reinforcement. The strength, resistance to harsh weather conditions, and aesthetic appeal of stainless steel make it a popular choice in architectural designs. 3. Food processing industry: Stainless steel coils are commonly utilized in the food processing industry for equipment such as food storage tanks, conveyors, and processing machinery. Stainless steel's hygienic properties, resistance to corrosion, and ease of cleaning make it suitable for maintaining the purity and safety of food products. 4. Chemical industry: Stainless steel coils find extensive usage in the chemical industry due to their excellent resistance to corrosion from chemicals and harsh environments. They are used in the production of storage tanks, pipelines, and reactors that handle various chemicals and corrosive substances. 5. Energy industry: Stainless steel coils are widely employed in the energy sector for applications such as power generation, oil and gas exploration, and renewable energy systems. They are used in heat exchangers, turbine components, pipelines, and offshore structures due to their high resistance to corrosion, strength, and longevity. 6. Medical and pharmaceutical industry: Stainless steel coils are commonly used in medical and pharmaceutical applications due to their biocompatibility and resistance to corrosion. They are used in the production of surgical instruments, medical implants, and medical equipment that require sterilization and durability. 7. Automotive industry: Stainless steel coils are utilized in the automotive sector for various components like exhaust systems, fuel tanks, catalytic converters, and structural parts. Stainless steel's high heat resistance, strength, and resistance to corrosion and oxidation make it suitable for these applications. These are just a few examples of the wide range of applications of stainless steel coils. Their versatility, durability, and resistance to corrosion make them indispensable in numerous industries where reliability and longevity are crucial factors.

- Q: How do steel coils contribute to the oil and gas industry?

- Steel coils are an essential component in the oil and gas industry as they are used to manufacture various equipment and structures like pipelines, storage tanks, and drilling rigs. These coils provide the necessary strength, durability, and resistance to corrosion required for the harsh operating conditions in the industry. Additionally, steel coils are crucial in the transportation of oil and gas as they are used in the construction of tankers and pipelines, ensuring the safe and efficient movement of these valuable resources.

- Q: What are the different types of steel coil surface treatments for durability?

- The durability of the material can be enhanced through various types of steel coil surface treatments. 1. To achieve a protective zinc coating on the surface, the steel coil is immersed in a bath of molten zinc in the process of hot-dip galvanizing. This method not only provides excellent corrosion resistance but also extends the lifespan of the steel coil. 2. For indoor applications or when a thinner coating is desired, electro-galvanizing is preferred. This method involves electrodeposition of a thin layer of zinc onto the surface of the steel coil, offering good corrosion resistance. 3. By applying a dry powder paint to the steel coil's surface and curing it under heat, powder coating creates a durable and attractive finish. This finish is resistant to chipping, scratching, and fading, ensuring a uniform appearance. 4. To protect against corrosion, UV rays, and other environmental factors, organic coatings like acrylics, polyesters, or fluoropolymers are commonly applied to steel coils. These coatings not only enhance durability but also improve the aesthetics of the steel coil. 5. Chromate conversion coating involves applying a thin layer of chromate onto the steel coil's surface. This treatment provides corrosion resistance and improves the adhesion of subsequent paint or powder coating layers. Each of these surface treatments offers unique benefits in terms of corrosion resistance, durability, and appearance. The choice of treatment depends on the specific application requirements and the level of protection needed for the steel coil.

- Q: How are steel coils inspected for weldability?

- A series of comprehensive tests and examinations are carried out to inspect the weldability of steel coils. The main objective of this inspection is to assess the quality and suitability of the steel coils for welding purposes. To begin with, a visual inspection is conducted to identify any visual defects or irregularities present on the surface of the coils. This includes checking for factors such as surface roughness, cracks, scratches, or any other imperfections that might affect the weldability. Following this, destructive testing methods, such as tensile testing and impact testing, are performed. Tensile testing measures the strength and ductility of the steel, ensuring that it meets the required mechanical properties for welding. Impact testing evaluates the steel's ability to resist brittle fracture, which is crucial in determining its weldability. In addition, non-destructive testing techniques like ultrasonic testing (UT) and magnetic particle inspection (MPI) are employed to detect any internal defects or discontinuities. UT utilizes high-frequency sound waves to identify hidden flaws within the steel, while MPI uses magnetic particles to identify defects on or near the surface. Moreover, chemical analysis is carried out to determine the composition of the steel and ensure that it meets the required specifications for welding. This analysis involves checking the levels of carbon, manganese, sulfur, and other elements that may impact the weldability and overall performance of the steel. Furthermore, weldability testing is performed to evaluate how the steel responds to welding processes. This involves conducting various welding trials using different techniques and parameters to assess the steel's behavior during welding, including its susceptibility to cracking, distortion, or other welding-related issues. In conclusion, the inspection of steel coils for weldability is a comprehensive process that involves visual inspection, destructive testing, non-destructive testing, chemical analysis, and weldability testing. Through these thorough inspections, manufacturers can ensure that the steel coils meet the required standards and are suitable for welding applications.

- Q: exactly what is the differance between strontuim steel and stainless steel any differances as far as hardness .... need help.

- Strontium steel is created by soaking a mild steel in strontium chromate, which has a pH of about 4 or 5, roughly the equivalent of acid rain. Chromate affects the cathodic reaction, with reduction of Cr6+ to Cr3+, and the surface film was composed of magnetite and hydrated chromium hydroxide. The Strontium is a radioactive isotope. The acid bath permeates the mild steel causing it to become mildly radioactive. Simular to oil imprengation of brass and other metals. Strontium Steel has a very high value of inhibition. However due to it's radioactive properties it is not a commonly used or manufactured material. As for where to actually obtain Strontium steel dowels. I have no idea i would speculate that you would have to purchase the raw stock and have it machined into a dowel for you.

Send your message to us

2mm Cold Rolled Steel Sheet Iron Steel China Suppliers

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords