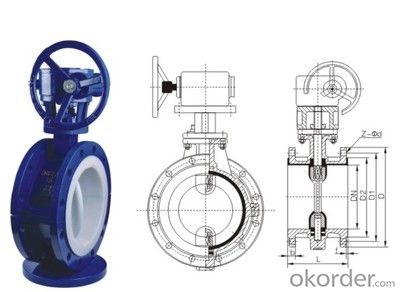

2inch Worm gear operated PTFE seated wafer type DI plated butterfly valves

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technical data

Nominal diameter | DN(mm) | 40-600 | |

Nominal pressure | PN(mpa) | 1.0 | 1.6 |

Test pressure(Mpa) | Shell test | 1.5 | 2.4 |

Test pressure(Mpa) | Seal test | 1.1 | 1.76 |

Appropriate medium | Air,water,sewage,steam,coal gas,oil | ||

Drive modality | Handle,worm gear box, penumatic drive,electric drive | ||

Material for main parts

Parts name | Material |

Body | Ductile cast iron,cast steel,Alloy steel, stainless steel |

Disc | Grey cast iron,ductile cast steel,cast steel,stainless steel and hoc material |

Seal ring | Manifold rubber,such as EPDM, PTFE,NBR,Viton,CR |

Stem | steel,ss420,ss304,ss316 |

Packing | O-ring,flexible graphite |

Butterfly valve seal material choice and apporpriate tempersture

Material variety | Neoprene | Styene rubber | EPDM | PTFE | Silicon rubber | Fluorine rubber |

Resistance highest temperature | 82°C | 93°C | 150°C | 232°C | 250°C

| 204°C |

Resistance lowest temperature | -40°C | -40°C | -40°C | -268°C | -70°C | -23°C |

Suitable working temperature | ≤65°C | ≤80°C | ≤120°C | ≤200°C | ≤200°C | ≤180°C |

Name | Material |

Body | ductile cast iron, WCB, stainless steel |

Disc | ductile cast iron, WCB stainless steel, Al-bronze |

Stem | SS420, SS431 or as request |

Disc seat ring | EPDM |

Body seat ring | SS304 |

Retainer | SS304 |

Shaft bearing | Al-bronze, self-lubricating bearing |

Bolt & nuts | SS304 |

Coating | epoxy coating, thickness: min. 250 microns, color code: RAl5015, 5017, 5010, and etc. |

China National Building Materials Group Corporation (CNBM) was established in 1984 with approval from the State Council, and then became a Central Enterprise under direct supervision of State-owned Assets Supervision and Administration Commission of the State Council in 2003.

Upholding the philosophy of “Making Best Use of Resources to Serve Construction”, and vigorously carrying out such strategies as “technical innovation”, “internationalization of building materials”, and “building strength with talents”, CNBM is the largest comprehensive building materials industry group in China that integrates scientific research, manufacturing and logistics into one entity, and consists of four business platforms, i.e. industry, technology, complete set of equipment, and trading & logistics. As of the end of 2009, CNBM’s total assets exceeded RMB 110 billion, with 100,000 employees, and 20 companies under direct management with 100% share control or majority control, among which 6 were listed companies, including 2 overseas listed.

CNBM practices the parent-subsidiary management system, and is one of those wholly state-owned enterprises carrying out the pilot trial of Board of Directors system and innovation system. As the strategic center, decision center, resources center, and policy & culture center, our Group exercises its right as a contributor. Whereas, our sub-groups functioning as business platforms, are mandated to construct the profit center based on their core competences to enlarge brand awareness and increase market share.

- Q: What are the factors to consider when selecting the appropriate steel grade for welding?

- When selecting the appropriate steel grade for welding, there are several factors to consider. These include the desired strength and hardness of the weld, the intended application or industry requirements, the welding process to be used, the base metal properties, the desired weldability and ease of fabrication, the availability and cost of the steel grade, and any specific requirements such as corrosion resistance or impact toughness. Additionally, factors such as the welding environment, the thickness of the base metal, and any post-weld heat treatment requirements should also be taken into account. Overall, a thorough evaluation of these factors will help ensure the selection of the most suitable steel grade for welding.

- Q: What are the applications of steel in the food processing industry?

- Steel is widely used in the food processing industry due to its various beneficial properties. It is commonly employed in the construction of machinery, equipment, and storage containers. Stainless steel, in particular, is highly resistant to corrosion, making it ideal for food contact surfaces and ensuring the safety and hygiene of food products. Additionally, steel's durability and strength make it suitable for heavy-duty applications such as food processing machinery, conveyors, and cutting tools. Overall, steel plays a crucial role in maintaining food quality, safety, and efficiency in the food processing industry.

- Q: What are the different types of steel products used in the manufacturing of pet accessories?

- There are various types of steel products used in the manufacturing of pet accessories such as stainless steel bowls, metal crates and cages, steel chains or leashes, steel grooming tools, and steel tags or identification collars.

- Q: How is steel wire used in the production of suspension systems for vehicles?

- Steel wire is used in the production of suspension systems for vehicles as it provides strength, durability, and flexibility required to absorb shocks and maintain stability during vehicle movement. It is commonly used to create springs, such as coil springs, which help support the weight of the vehicle and provide a smoother ride by absorbing vibrations and impacts from uneven road surfaces. Additionally, steel wire is used in the production of sway bars, which help reduce body roll and improve overall handling and stability of the vehicle.

- Q: How is steel used in the production of electrical equipment?

- Steel is used in the production of electrical equipment due to its high strength and durability. It is commonly used to manufacture electrical enclosures, cabinets, and support structures for transformers, generators, and other heavy equipment. The steel components provide a robust and protective housing, ensuring the safety and longevity of the electrical equipment.

- Q: How is steel wire rope strength tested?

- Steel wire rope strength is typically tested using a method called a tensile test. This involves applying a gradually increasing force to the rope until it breaks, allowing researchers to determine its maximum load capacity and overall strength.

- Q: What are the common uses of steel in the telecommunications industry?

- Steel is commonly used in the telecommunications industry for various purposes such as supporting structures for cell towers, transmission line towers, and antenna mounts. It provides the necessary strength, durability, and stability required for the infrastructure of telecommunication networks.

- Q: How are steel forgings used in the production of power generation equipment?

- Steel forgings are used in the production of power generation equipment due to their exceptional strength, durability, and reliability. These forged components, such as turbine rotors, shafts, and casings, are able to withstand the extreme conditions and heavy loads associated with power generation. The forging process ensures a uniform grain structure, eliminating weak points and improving the overall performance and longevity of the equipment. Additionally, steel forgings can be customized to meet specific design requirements, allowing for efficient and safe power generation operations.

- Q: How is steel profiled and cut?

- Steel can be profiled and cut using various methods such as plasma cutting, laser cutting, waterjet cutting, and shearing. These methods involve the use of specialized machinery and tools to accurately shape and trim steel profiles according to specific dimensions and designs.

- Q: What are the applications of alloy steel in the energy sector?

- Alloy steel is widely used in the energy sector due to its exceptional strength, durability, and resistance to corrosion. It finds applications in various components such as pipelines, power generation equipment, turbines, and drilling equipment. The high strength-to-weight ratio of alloy steel makes it ideal for constructing structures that can withstand high pressures and temperatures, ensuring reliable and efficient energy production and transmission. Additionally, alloy steel's resistance to corrosion makes it suitable for use in harsh environments, such as offshore oil and gas platforms, where exposure to seawater and other corrosive substances is common.

Send your message to us

2inch Worm gear operated PTFE seated wafer type DI plated butterfly valves

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords