201 Stainless Steel Sheet 2mm hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

201 hot rolled stainless steel sheet 2mm

NAME | |

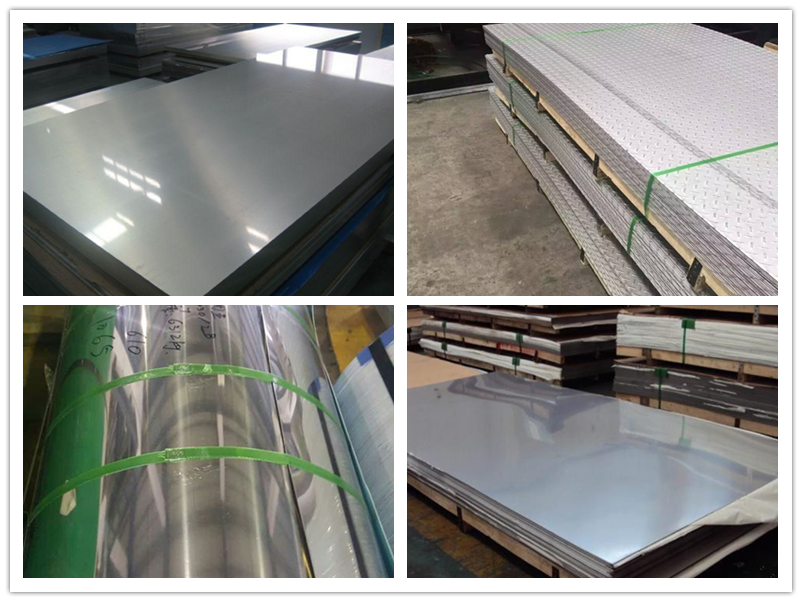

typ | Cold rolled;hot rolled |

thickness | 0.3-3mm;3mm-100mm |

Cold size | 1000mm*2000mm,1220mm*2440mm |

Hot size | 1500mm*6000mm |

Cold surface | 2B,BA,HL,8K,No.4,No.8 |

Hot surface | No.1 |

Material/Grade | 201,202,304,304L,321,316L,310S,317,4049L, etc. |

Standard | ASTMA240,ASTMA480,GB/T4237-1992,JIS |

Application | Auto or aircraft or construction industry,tableware,furniture , decoration for chemical equipment ,Industry purposes and building ornament, production manufacturing |

Place of Origin | Tianjin, China (Mainland) |

Brand Name | Tisco,Jisco,Baosteel,Lisco |

Technique | cold rolled ,hot rolled |

Certificate | ISO 9001:2008 |

Payment terms | T/T(recommended), L/c,western |

Leading time/Delivery Detail | Within 7-15 days after receipt of T/T or L/c at sight |

Packaging Detail | 1.with wooden pallets, or film covered, in the containers. 2.Export standard package or as the customers' demands. 3.seaworthy wooden cases, 4.with or without edge protector,steel hoop and seals, 5.export -ted standard package or as customers signal requirement |

Stock | Aways in stock |

Payment | 30% TT in advance, balance against copy B/L |

MOQ: | 1 TON |

Note

| We can produce other standard as the customers’ requirement

|

Producitivity | 10000Tons/Month |

1.We can supply you with reasonable and competitive price and good quality products. 2.If you are interested in any of products, please contact us for more information.

| |

Packaging & Shipping

Application

- Q: Do stainless steel sheets have a warranty?

- Yes, stainless steel sheets typically come with a warranty. The length and terms of the warranty may vary depending on the manufacturer or supplier. It is recommended to check with the specific company or review the product documentation for information on the warranty coverage.

- Q: How to calculate the weight of stainless steel plate?

- Stainless steel not only refers to a stainless steel, but more than one hundred kinds of industrial stainless steel, the development of each kind of stainless steel in its specific application areas have good performance. The key to success is to find out what the purpose is, and then determine the correct type of steel.

- Q: What are the common sizes of stainless steel sheets?

- Common sizes of stainless steel sheets vary depending on the industry and application. However, there are some standard sizes that are readily available in the market. For instance, stainless steel sheets commonly come in thicknesses ranging from 0.4mm to 3.0mm. The most common widths are 1000mm, 1219mm, and 1500mm, while the most common lengths are 2000mm, 2438mm, and 3000mm. These dimensions are often referred to as 4x8 (4 feet by 8 feet), as they are the standard size for stainless steel sheets used in various construction and fabrication projects. It's worth noting that stainless steel sheets can also be custom-cut to specific dimensions based on the requirements of a particular project. This allows for greater flexibility and ensures that the sheets fit perfectly for the intended application.

- Q: What are the cost considerations when purchasing stainless steel sheets?

- The cost considerations when purchasing stainless steel sheets include the grade and quality of the stainless steel, the size and thickness of the sheets, any additional finishes or coatings, and the quantity being purchased. Additionally, factors such as transportation and delivery costs, as well as any applicable taxes or import duties, should also be taken into account.

- Q: Are stainless steel sheets resistant to saltwater?

- Indeed, saltwater poses no threat to stainless steel sheets. Renowned for its ability to resist corrosion, stainless steel demonstrates exceptional suitability for environments with extensive saltwater contact. The chromium present in stainless steel creates a protective layer over the metal's surface, effectively warding off rust and corrosion. As a result, stainless steel sheets prove to be an exceptional option for various marine applications, including boat construction, offshore structures, and coastal infrastructure. Moreover, stainless steel's resilience against saltwater renders it fitting for other purposes such as coastal architecture, kitchen equipment, and medical instruments.

- Q: How do I prevent corrosion under insulation on stainless steel sheets?

- To prevent corrosion under insulation on stainless steel sheets, there are several steps you can take: 1. Proper insulation selection: Choose insulation materials that are compatible with stainless steel and have a low water absorption rate. Avoid using materials that can cause galvanic corrosion when in contact with stainless steel. 2. Adequate insulation thickness: Ensure that the insulation thickness is sufficient to prevent moisture condensation on the stainless steel surface. Condensation can trap moisture and accelerate corrosion. Consult with an insulation specialist to determine the appropriate thickness for your specific application. 3. Vapor barriers: Install vapor barriers between the insulation and the stainless steel sheets. Vapor barriers act as a moisture barrier, preventing the ingress of water or moisture that can lead to corrosion. These barriers can be made of materials such as foil or plastic films. 4. Proper installation: Ensure that the insulation is properly installed, with no gaps or areas where moisture can accumulate. Pay close attention to joints, seams, and connections, making sure they are tightly sealed to prevent water penetration. 5. Regular inspection and maintenance: Regularly inspect the insulation system to identify any signs of damage, such as leaks or deterioration. Promptly repair any damaged insulation or vapor barriers to prevent moisture from reaching the stainless steel surface. 6. Ventilation: Provide adequate ventilation to prevent moisture buildup in enclosed spaces. Good airflow can help reduce the chances of condensation and subsequent corrosion. 7. Cathodic protection: Consider using cathodic protection methods, such as sacrificial anodes or impressed current systems, to protect stainless steel sheets from corrosion. These methods create an electrical current that counteracts the corrosion process, extending the lifespan of the stainless steel. Remember, it is essential to consult with corrosion specialists or insulation experts to ensure the best practices are implemented for your specific application and environment.

- Q: Can stainless steel sheets be used for elevator shafts?

- Yes, stainless steel sheets can be used for elevator shafts. Stainless steel is a durable and corrosion-resistant material that is commonly used in construction for its strength and aesthetic appeal. Elevator shafts require materials that can withstand constant use and exposure to various elements, making stainless steel an ideal choice.

- Q: How do you calculate the bending radius for stainless steel sheets?

- In order to determine the bending radius for stainless steel sheets, several factors need to be taken into consideration. To begin with, the thickness of the stainless steel sheet must be determined. Thinner sheets necessitate smaller bending radii, whereas thicker sheets can accommodate larger radii. The type of stainless steel being used should also be identified. Various grades of stainless steel possess different levels of ductility, which impacts their ability to be bent. Higher ductility allows for smaller bending radii. Furthermore, the desired angle of the bend should be considered. The sharper the angle, the smaller the bending radius required. To calculate the bending radius, the following formula can be utilized: Bending Radius = (2 x Sheet Thickness) + (Bend Angle x Sheet Thickness) For instance, if a stainless steel sheet has a thickness of 0.5mm and a 90-degree bend is desired, the bending radius would be: Bending Radius = (2 x 0.5mm) + (90 x 0.5mm) = 1mm + 45mm = 46mm It is essential to note that this formula serves as a general guideline and may vary depending on the specific properties of the stainless steel being used. Consulting technical specifications or manufacturers' guidelines is always recommended for accurate bending radius calculations.

- Q: What are the different types of stainless steel sheet surface patterns?

- There are several different types of stainless steel sheet surface patterns that are commonly used in various industries. Some of the most common patterns include: 1. No. 1 Finish: This is the most common type of stainless steel sheet surface pattern. It has a dull, rough, and non-reflective finish, which is achieved by hot rolling the stainless steel sheet. 2. No. 2B Finish: This type of finish has a smooth, moderately reflective surface. It is achieved by cold rolling the stainless steel sheet and then annealing it in a controlled atmosphere to remove any scale or oxide buildup. 3. No. 3 Finish: This finish is similar to the No. 2B finish, but with a slightly coarser and less reflective surface. It is commonly used for decorative purposes, such as in architectural applications. 4. No. 4 Finish: This is a popular choice for stainless steel sheet surfaces. It has a brushed appearance, with fine parallel lines running in one direction. The brushed finish is achieved by using abrasive belts or brushes to create a consistent pattern on the surface. 5. No. 8 Mirror Finish: As the name suggests, this finish provides a highly reflective, mirror-like surface. It is achieved by polishing the stainless steel sheet to a high shine using a series of progressively finer abrasive materials. 6. Embossed Finish: This finish features a raised, textured pattern on the surface of the stainless steel sheet. It can be achieved through various methods, such as embossing rollers or heat transfer. 7. Bead Blasted Finish: This finish has a uniform, matte appearance with a slightly rough texture. It is created by bombarding the stainless steel sheet with fine glass beads at high pressure, resulting in a consistent, non-reflective surface. Each of these stainless steel sheet surface patterns offers unique aesthetic and functional qualities. The choice of pattern depends on the specific application and desired outcome, whether it be for architectural, industrial, or decorative purposes.

- Q: What are the common sizes and thicknesses of stainless steel sheets?

- The sizes and thicknesses of stainless steel sheets vary depending on their intended use and industry standards. However, there are standard sizes and thicknesses commonly found in the market. Stainless steel sheets are commonly available in sizes ranging from 4x8 feet (1219x2438mm) to 5x10 feet (1524x3048mm). These sizes are widely used in construction, automotive, and fabrication applications. In terms of thickness, stainless steel sheets come in a range of gauges, typically measured in inches or millimeters. The most frequently used thicknesses are 0.0276 inches (0.7mm), 0.0359 inches (0.91mm), 0.0478 inches (1.21mm), 0.0598 inches (1.52mm), 0.0747 inches (1.90mm), and 0.0897 inches (2.28mm). These thicknesses find frequent application in commercial and industrial settings. It is important to note that stainless steel sheets can be customized to meet specific requirements, encompassing non-standard sizes and thicknesses. In such instances, it is advisable to seek guidance from a supplier or manufacturer who can offer tailored solutions based on the project's unique needs.

Send your message to us

201 Stainless Steel Sheet 2mm hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords