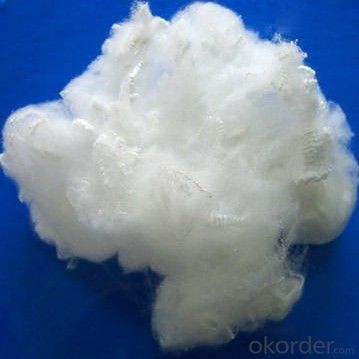

15D *64 Hollow Conjugated Non Siliconizied Polyester Fiber

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

15D *64 Hollow Conjugated Non Siliconizied Polyester Fiber

Specification of 15D *64 Hollow Conjugated Non Siliconized Polyester Fiber

Denier:15D

Length:64mm

Feature:hollow, non-siliconized

Grade:recycled

Package of 15D *64 Hollow Conjugated Non Siliconizied Polyester Fiber

Each bale is around 300kg, packed with PP woven bag

Application of 15D *64 Hollow Conjugated Non Siliconizied Polyester Fiber

Filing and stuffing material for clothes, quilt,bedding, toys and furniture etc.

FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of PP staple fiber which is used as the raw material of textile, automotive interior etc. We have exported this product to Amereica, Europe and South East Asia. Customized product is also available based on your detailed requirements.

2> What's the MOQ ?

We kindly recommend 1x40'HQ as the price would be economical based on large loading quantity.

3>How long can we receive the product after purchase?

It takes about 1 to 2 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: What is optical fiber? What's the use of it?

- The ability of fiber to transmit light is very strong, and it can transmit large amounts of information simultaneously with optical fiber communication. For example, an optical cable channel can accommodate one billion people at the same time, can also transmit multiple sets of television programs. The anti-interference performance of the optical fiber is good, the electric radiation is not occurred, the communication quality is high, and the eavesdropping can be prevented. Optical fiber cable is small and fine, not afraid of corrosion, laying is also very convenient, so it is very good communication materials. At present, many countries have used optical fiber cable as long-distance communication trunk. Our country also began to produce optical fiber, and it was put into use in some areas and cities. With the progress of the times and the development of science, optical fiber communication will be greatly popularized.

- Q: What is the welding process of cellulose welding?

- Using cellulose electrode, there are more cellulose components in the electrode coating, and the arc blow force is larger;

- Q: What are the differences between automotive carbon fiber stickers and films? Who knows the industry, please point out!

- The so-called carbon fibre seems many: some of the name of 3M foundry (not to disclose the name), Belgium (a company, respect gelatinous Caidie agent, the price is a bit high, Mike should also stick).Butterflies and Mike stick is in Belgium, tariffs to the hands of consumers at least more than 200 / square meters.

- Q: How to judge whether it is bamboo fiber?

- Good Sari bamboo fiber socks and the appearance of bright color, high color fastness, not because of such factors as the sun washed easily decolorization, poor color or color is dull, obvious, or easy bleaching.

- Q: Polyester and polyester fabrics are good

- Polyester and polyester fiber and their application in the field of clothing each one has his good points. Polyester fabric refers collectively blended polyester and cotton fabric, with 65% - 67% and 33% - 35% of the polyester cotton blended yarn woven into textiles, commonly known as cotton dacron, polyester cotton has highlighted both polyester and cotton fabric style strengths, in dry and wet conditions and better flexibility and abrasion resistance, stable size, small shrinkage, with tall and straight, not easy to fold, easy washing and drying characteristics of a plain weave, twill, canvas, Oxford spun silk yarn, thread silk, satin and other varieties; in the finishing of special additives such as Teflon three, suitable for the production of clothing, clothing and special occupation. Casual clothing.

- Q: Structural performance difference between polyacrylonitrile and carbon fiber

- Carbon fibers are formed by pre oxidation and carbonization of polyacrylonitrile.

- Q: What's the difference between polyester fiber and cotton?

- Polyester is synthetic, cotton is pure natural.

- Q: What is nonwoven fiber?

- Textile made from textile fibers and processed by adhesion, fusion, or other chemical or mechanical methods. This textile is not the traditional spinning, weaving or knitting process, also known as non-woven fabrics, non-woven fabrics.

- Q: Will the clothes of polyester fiber shrink in hot water?

- Polyester fiber commonly known as what we often call polyester, and its hydrophilic is relatively poor, so it will not absorb water, which will not cause much shrinkage.

- Q: Acrylic fiber is man-made or synthetic fiber, customs declaration form when used

- Acrylic fiber is synthetic fiber, artificial fiber, including rayon, artificial cotton and so on.

Send your message to us

15D *64 Hollow Conjugated Non Siliconizied Polyester Fiber

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches