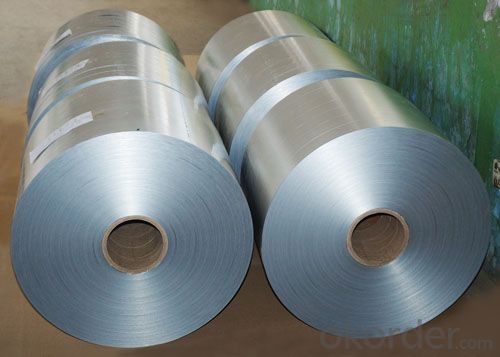

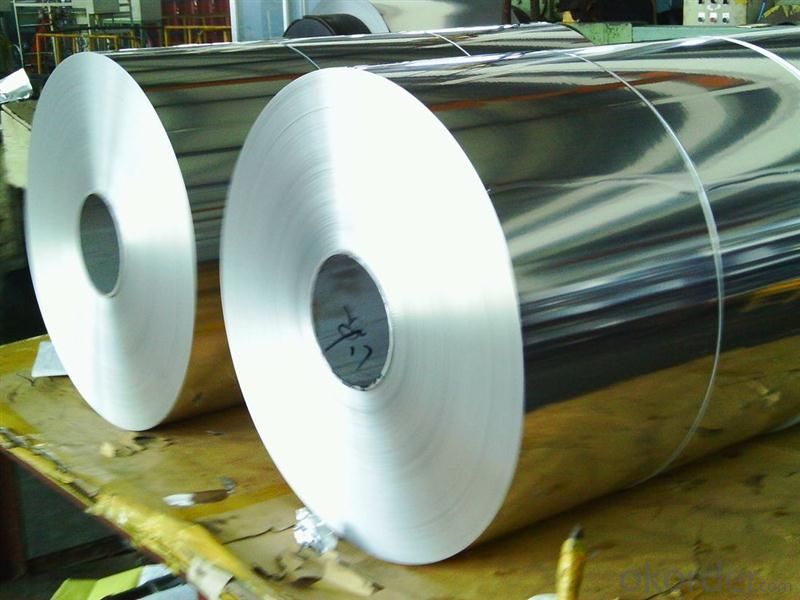

Aluminum Coil 1100 5754 Mirror Cost Insulation Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1100 5754 Mirror Cost Insulation Aluminum Roll

Applications:

Aluminum foil roll is widely used in construction,decoration,hardware,

electric appliances,machinery and other industrial and civil purposes,

such as electronic capacitor,composite cooker,rice cooker,refrigerator,

computer casting,telecommunication,equipment,lamp shade,air conditioner,

cosmetics cover and so on.

Or it can be made as customers’ requirement.

Specifications

color aluminum coil

1000 series 1100 10160 1200

surface could be: Brushed, drawing, embossed, printing

color: red,

color aluminum coil

.Alloy type: 1050/1060/1100/1350

2.Temper: H16, H18, H22, H24

3.Thickness range: 0.1mm-4mm

4.Width range: 25mm-1600mm

5.Surface:finish: bright & smooth surface, without flow lines, slight oiled to avoid white rusting.

6.Quality material:totally free from such defefects as roll marks, edge damager, camber, white rust, oil patches, holes, break lines,

color aluminum coil

Name |

color aluminum coil |

Alloy or not | yes |

Alloy | 1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc. |

Thickness | 0.1-4mm |

Width | ≤1600mm |

MOQ | 5T |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

- Q: Can aluminum coils be used in aerospace heat exchangers?

- Yes, aluminum coils can be used in aerospace heat exchangers. Aluminum is a commonly used material in the aerospace industry due to its lightweight and high thermal conductivity properties. Heat exchangers are crucial components in aerospace systems, responsible for transferring heat from one medium to another. Aluminum coils are highly effective in conducting heat, making them suitable for use in aerospace heat exchangers. Additionally, aluminum is corrosion-resistant, which is important in the harsh environments encountered in aerospace applications. Its low density also contributes to fuel efficiency by reducing the overall weight of the aircraft. Therefore, aluminum coils are a preferred choice for aerospace heat exchangers due to their excellent thermal conductivity, lightweight properties, and resistance to corrosion.

- Q: What are the rules or laws governing the use of aluminum coils?

- <p>Yes, there are regulations on the use of aluminum coils, which vary by country and industry. These regulations often pertain to safety, quality standards, and environmental impact. For instance, in the construction industry, aluminum coils used for roofing or cladding must meet specific standards for strength and durability. In food packaging, regulations may dictate the type of aluminum alloys used to prevent contamination. Additionally, there are environmental regulations that govern the disposal and recycling of aluminum coils to minimize their impact on the environment. Compliance with these regulations is crucial for manufacturers, suppliers, and users of aluminum coils to avoid legal penalties and ensure public safety.</p>

- Q: Can aluminum coils be used in automotive body panels?

- Yes, aluminum coils can be used in automotive body panels. Aluminum is lightweight, corrosion-resistant, and offers excellent strength-to-weight ratio, making it an ideal material for automotive applications. Its use in body panels helps improve fuel efficiency and reduce vehicle weight while maintaining structural integrity.

- Q: The company wants to produce an aluminum coil production line, which is better for large aluminium smelting equipment?

- Dongpu heat well, they have the qualification certificate issued by the state kiln construction, as far as I know, their melting furnace Aluminum Alloy 'plan is very good, and the operation is simple and safe, feel good, can be wiped off

- Q: Can aluminum coils be used in agricultural applications?

- Yes, aluminum coils can be used in agricultural applications. Aluminum is a versatile and durable material that can withstand various environmental conditions, making it suitable for agricultural equipment such as irrigation systems, greenhouse structures, and ventilation systems. Additionally, aluminum's light weight and corrosion-resistant properties make it an ideal choice for agricultural applications where durability and long-term performance are essential.

- Q: Can aluminum coils be used for roofing?

- Yes, aluminum coils can be used for roofing. Aluminum is a popular choice for roofing materials due to its durability, lightweight nature, and resistance to corrosion. Aluminum roofing coils are frequently used in various types of roofs, including residential, commercial, and industrial buildings. They offer excellent protection against extreme weather conditions, such as heavy rain, snow, and high winds. Additionally, aluminum coils are energy-efficient as they can reflect heat from the sun, helping to keep the building cool and reducing energy costs. Overall, aluminum coils provide a reliable and long-lasting roofing solution.

- Q: What are the cost implications of using aluminum coils?

- The cost implications of using aluminum coils can vary depending on various factors. Firstly, aluminum coils tend to be more expensive than other types of coils, such as copper coils. This is mainly due to the higher cost of raw materials and the energy-intensive manufacturing process involved in producing aluminum coils. Therefore, the initial purchase cost of aluminum coils may be higher compared to other options. However, it is important to consider the long-term cost implications. Aluminum coils are known for their durability and resistance to corrosion, which can result in longer service life compared to other materials. This can lead to reduced maintenance and replacement costs over time. Additionally, aluminum is lightweight, making it easier to handle and transport, potentially reducing labor and transportation costs. Another cost implication to consider is the energy efficiency of aluminum coils. Aluminum has excellent heat transfer properties, allowing for efficient heat exchange in various applications, such as HVAC systems or refrigeration units. This can result in lower energy consumption and subsequently lower operating costs in the long run. Furthermore, aluminum is a highly recyclable material, which can contribute to cost savings and environmental benefits. Recycled aluminum can be used in the production of new coils, reducing the need for virgin materials and lowering overall costs. It is important to note that these cost implications may vary depending on the specific application and usage requirements. Factors such as the size of the system, installation complexity, and maintenance practices can also impact the overall cost-effectiveness of using aluminum coils. In summary, while aluminum coils may have a higher initial purchase cost, their durability, resistance to corrosion, energy efficiency, and recyclability can result in long-term cost savings and environmental benefits.

- Q: I know this question is not so bright, but I am very curious why do we recycle aluminum cans? Is it that they are not biodegradable?

- We recycle cans as to save energy (and money) as the processing of aluminum cans from raw materials is very energy intensive, thus remelting them down and processing new aluminum products reduces energy use.

- Q: How do aluminum coils impact energy efficiency?

- Aluminum coils play a crucial role in enhancing energy efficiency in various applications. They are commonly used in heating, ventilation, and air conditioning (HVAC) systems, refrigerators, and heat pumps. The primary reason for their positive impact on energy efficiency is their excellent heat transfer properties. Aluminum is an excellent conductor of heat, which means it can quickly absorb and dissipate thermal energy. When used in HVAC systems, aluminum coils facilitate the transfer of heat between the indoor and outdoor units. This efficient heat transfer reduces the workload on the system, allowing it to operate more efficiently and consume less energy. Additionally, aluminum coils are lightweight and have a high surface area, which further enhances their heat transfer capabilities. Their lightweight nature reduces the overall weight of the system, resulting in lower energy consumption. The increased surface area allows for greater contact between the air and the coils, promoting more effective heat exchange. Furthermore, aluminum coils are resistant to corrosion, which is a common issue in HVAC systems. Corrosion can negatively impact the efficiency of heat transfer, leading to increased energy consumption. Aluminum coils' resistance to corrosion ensures long-lasting performance, maintaining their efficiency and reducing the need for frequent maintenance or replacement. In summary, aluminum coils contribute significantly to energy efficiency by facilitating efficient heat transfer, reducing the workload on HVAC systems, and minimizing energy consumption. Their lightweight nature, high surface area, and corrosion resistance further enhance their positive impact on energy efficiency.

- Q: Explain the differences between aluminum coils and iron coils, including their properties and applications.

- <p>Aluminum coils and iron coils differ in material composition, weight, strength, and applications. Aluminum coils are made of aluminum, a lightweight, corrosion-resistant metal, while iron coils are made from iron, which is heavier and more prone to rust. Aluminum coils have a lower density, making them ideal for applications where weight is a concern, such as in construction or automotive industries. They also have excellent electrical and thermal conductivity. Iron coils, on the other hand, are stronger and more durable, making them suitable for heavy-duty applications like construction reinforcement and machinery parts. Iron is also magnetic, which is an advantage in certain applications. However, iron is more susceptible to corrosion and requires protective coatings or treatments to extend its lifespan.</p>

Send your message to us

Aluminum Coil 1100 5754 Mirror Cost Insulation Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords