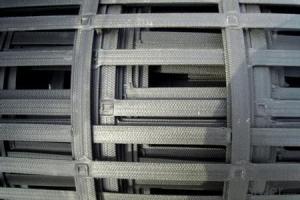

Tx7 Geogrid

Tx7 Geogrid Related Searches

Fridge With Freezer On Bottom Driveway Pillars With Lights Blu Ray Player With Recorder Blu Ray Player With Internet Geogrid In Retaining Walls 1708 Biaxial Fiberglass Tape Pullout Resistance Of Geogrid Geogrid Warp Knitting Machine Srw 3 Series Geogrid Biaxial Plastic GeogridHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Ex Display Log Cabins For Sale Photoelectric Cells For Sale Athletic Lockers For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For SaleTx7 Geogrid Supplier & Manufacturer from China

Okorder.com is a professional Tx7 Geogrid supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Tx7 Geogrid firm in China.Hot Products

FAQ

- What is the coefficient of friction of Nonwoven Geotextiles (polypropylene)?

- Such as artificial lakes, swimming pools, reservoirs and other projects, and geotextile is generally used in landscaping or highway pavement health

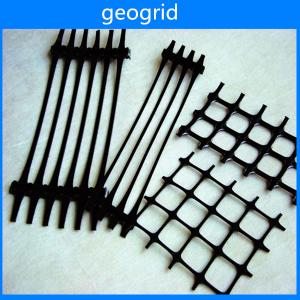

- Geogrids help in soil reinforcement by providing a strong and stable framework within the soil, preventing its movement and improving its load-bearing capacity. They act as a tensional element, distributing the applied loads and reducing the stress on the soil. This reinforcement helps in preventing soil erosion, improving slope stability, and enhancing the overall performance and longevity of various civil engineering structures.

- The tensile strength of geogrids can vary depending on the specific type and design, but generally, it ranges from 20 to 200 kilonewtons per meter.

- Geogrids are generally resistant to acid degradation due to their composition and manufacturing process. They are typically made from high-quality, chemically stable polymers that are designed to withstand various environmental conditions, including exposure to acids. However, the exact resistance level may vary depending on the specific type and brand of geogrid.

- The factors that affect the durability of geogrids include the material composition and quality, manufacturing method, exposure to environmental conditions (such as UV radiation, temperature variations, and moisture), installation techniques, and proper maintenance.

- There are several installation methods for geogrids, including direct placement, trenching and backfilling, and mechanical installation. Direct placement involves laying the geogrid directly on the subgrade or soil surface and then covering it with a layer of aggregate. Trenching and backfilling method involves excavating a trench, placing the geogrid in the trench, and then backfilling it with soil or aggregate. Mechanical installation methods use specialized equipment, such as a geogrid installation machine, to unroll and place the geogrid in the desired location. The chosen installation method depends on factors such as the application, site conditions, and specific project requirements.

- Yes, geogrids can be used in railway track stabilization. Geogrids are commonly used in civil engineering projects to improve soil stability, reinforce weak subgrades, and minimize lateral movement. In railway track stabilization, geogrids can be installed beneath the ballast layer to enhance load distribution, reduce track settlement, and increase the overall strength of the track system.

- Yes, geogrids can be used in floating road construction. Geogrids are often used to reinforce and stabilize the subgrade in road construction projects, including floating roads. They provide additional strength and stability to the road structure, allowing it to withstand heavy loads and prevent deformation.