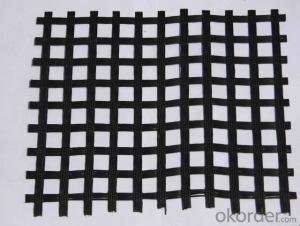

PVC Coated Polyester Geogrid for Civil Engineering and Road Contruction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyester Geogrid Introduction

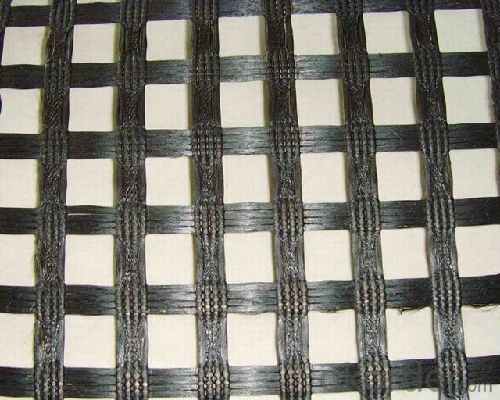

The warp knitting polyster geogrid use excel raw materials, with warp knitting oriented structrue , latitude and longitude in the fabric to the yarn between not curving condition, the intersection unifies mutually with the excel in textile fiber filament bundle, forms the reliable combining site, displays its mechanical properties fully.

Polyester Geogrid Features

Transmits high tensile forces with low elongation

High ultimate tensile strength

Excellent long-term behavior due to low creep effects

High resistance to soil micro-organisms and chemicals, UV radiation and mechanical damage

Good grid/soil interaction through optimum sizing of the geogrid mesh to suit the maximum coarse particle size of the soil

Ease of installation through low weight per unit area and flexible, adaptable structure

Very wide range of available strengths, uniaxial and biaxial structures

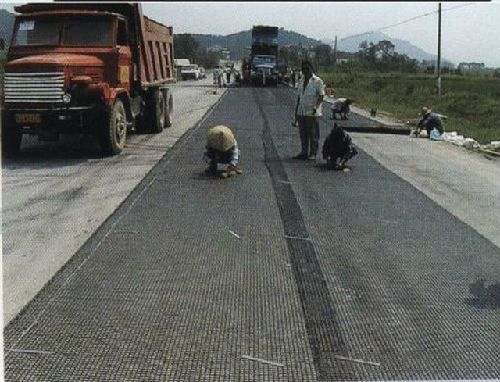

Polyester Geogrid Application

Structural layers supporting road, railway and airport construction

Site access roads and transport routes

Retaining walls and steepened slopes

Slope stabilization

Noise reduction barriers

Rehabilitation of waste ground

Earth embankments over piles

Landfill

Bridging of voids and sinkholes

Polyester Geogrid Specifications

Property | Test Method | PET | PET | PET | PET | |

40-25 | 50-35 | 60-30 | 80-30 | |||

Ultimate tensile strength(1)(kN/m) | MD | EN ISO 10139 | 25 | 35 | 30 | 30 |

CD | 40 | 50 | 60 | 8 | ||

Elongation at maximum load(%) | MD | 13 | ||||

CD | 13 | |||||

Approximate mesh size(mm) | 12.7mm×12.7mm , 25.4mm×25.4mm , 40mm×40mm | |||||

Roll Width (m) | 1m-6m | |||||

Roll Length(m) | 50m-200m | |||||

FAQ

1. What's the usage of geogrid?

It's used for reinforce the roadbeds in softe soil, railway, tunnel, slope and embankment etc. It has good performance on preventing the cracks.

2. How about your quality of geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

Polyester Geogrid Product Photos

- Q:Three how much is the price of Geogrid

- Modulus, modulus, price range

- Q:Are geogrids suitable for erosion control?

- Yes, geogrids are suitable for erosion control. Geogrids are often used as a reinforcement material in soil stabilization and erosion control applications. These synthetic materials are designed to improve the stability and strength of the soil, preventing erosion and soil displacement. Geogrids can effectively distribute loads, reduce water flow velocity, and enhance the overall performance of erosion control measures.

- Q:Can geogrids be used in soil stabilization for airport runways?

- Yes, geogrids can be used in soil stabilization for airport runways. Geogrids are commonly used to reinforce and stabilize soil in various engineering applications, including airport runway construction. They provide increased strength and stability to the soil, preventing it from shifting or settling under the weight of aircraft and heavy loads. Geogrids can improve the overall performance and longevity of airport runways by enhancing their load-bearing capacity and reducing the risk of pavement failure.

- Q:How do geogrids improve the stability of shorelines?

- Geogrids improve the stability of shorelines by providing reinforcement and preventing soil erosion. They are typically installed beneath the surface of the shoreline, creating a strong and stable foundation. Geogrids help distribute the load of the soil and wave forces, reducing the risk of slope failure or collapse. Additionally, they enhance the soil's resistance to erosion caused by waves, currents, or wind, ultimately preserving the shoreline's integrity and preventing further degradation.

- Q:How do geogrids enhance the stability of steep railway embankments?

- Geogrids enhance the stability of steep railway embankments by providing reinforcement and confinement to the soil. They are placed within the embankment, creating a strong and stable structure that can withstand the forces of gravity and lateral movements. Geogrids distribute the load more evenly, reducing the risk of slope failure and erosion. Additionally, they improve the shear strength of the embankment, preventing soil movement and ensuring long-term stability.

- Q:Are geogrids resistant to chemicals and environmental degradation?

- Yes, geogrids are generally resistant to chemicals and environmental degradation. They are designed to withstand exposure to various chemicals and harsh environmental conditions, ensuring long-term durability and performance.

- Q:Are geogrids suitable for reinforcing railway subgrades?

- Yes, geogrids are suitable for reinforcing railway subgrades. Geogrids provide effective soil stabilization, improve load-bearing capacity, and reduce settlement, making them an ideal solution for reinforcing railway subgrades and ensuring long-term performance and stability of the tracks.

- Q:What is the difference between geogrids and geotextiles?

- Geogrids and geotextiles are both used in civil engineering and construction projects, but they have distinct differences in their design and function. Geogrids are typically made of high-strength polymer materials and have a grid-like structure, often resembling a net or mesh. They are primarily used to reinforce soil and provide stability to structures by distributing loads and reducing soil movement. Geogrids are commonly used in applications such as road and pavement construction, retaining walls, and slope stabilization. On the other hand, geotextiles are permeable fabrics made from synthetic fibers. They are designed to filter, separate, reinforce, or protect soil and other materials. Geotextiles can be woven or non-woven and are used for various purposes, including erosion control, drainage systems, filtration, and soil stabilization. They are often used in applications such as landscaping, erosion control blankets, and landfills. In summary, the main difference between geogrids and geotextiles lies in their structure and main function. Geogrids provide reinforcement and stability to soil and structures, while geotextiles are used for filtration, separation, and protection purposes.

- Q:How do geogrids reinforce slopes?

- Geogrids reinforce slopes by providing additional strength and stability to the soil. They are placed within the soil mass to distribute and carry the load, reducing the risk of slope failure. The geogrid's interlocking structure enhances soil cohesion, increasing its resistance to erosion and sliding. This reinforcement mechanism helps reinforce the slope, preventing slope movement and maintaining its integrity.

- Q:Can geogrids be used in landfill capping systems?

- Yes, geogrids can be used in landfill capping systems. Geogrids are commonly used in landfill capping systems to provide reinforcement and stability to the cover materials. They help distribute loads and reduce stress on the cover system, improving its integrity and performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Coated Polyester Geogrid for Civil Engineering and Road Contruction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords