Geogrid Long Life High Tensile Strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

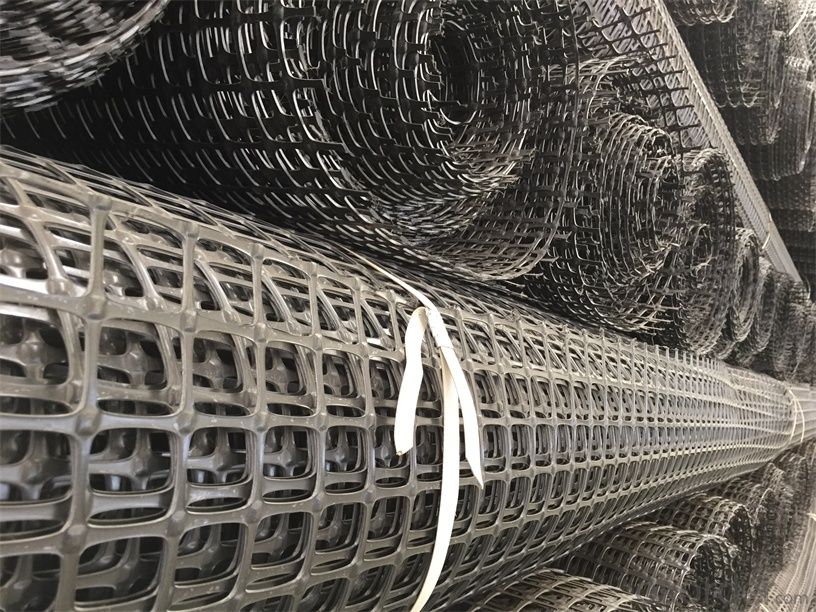

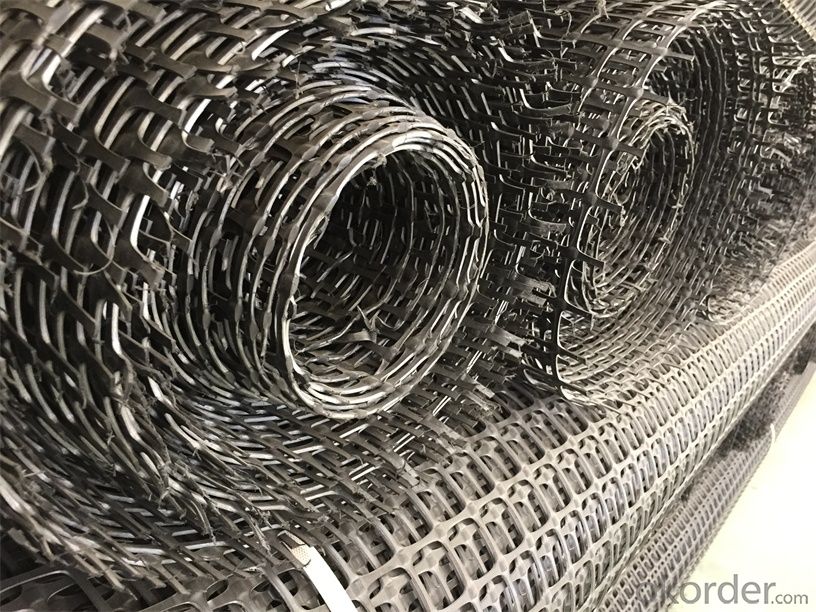

Geogrid Long Life High Tensile Strength Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Geogrid Long Life High Tensile Strength Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Geogrid Long Life High Tensile Strength Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Geogrid Long Life High Tensile Strength Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, we can help you.

- Q:What are the factors that affect the design of geogrid-reinforced structures?

- The factors that affect the design of geogrid-reinforced structures include the type and strength of geogrid material, soil properties (such as strength and settlement characteristics), loading conditions, design life requirements, construction techniques, and potential environmental factors (such as temperature variations and chemical exposure). Additionally, factors such as site-specific conditions, project constraints, and regulatory requirements may also influence the design of geogrid-reinforced structures. Overall, a comprehensive understanding of these factors is crucial to ensure the optimal design and performance of geogrid-reinforced structures.

- Q:Can geogrids be used in green roof systems?

- Yes, geogrids can be used in green roof systems. Geogrids provide structural support and reinforcement to the green roof system, helping to distribute the weight of the vegetation and prevent soil erosion. They also enhance the overall stability and longevity of the green roof by reducing the lateral movement of the soil and preventing settlement.

- Q:Can geogrids be used in reinforcement of bridge abutments on expansive soils?

- Yes, geogrids can be used in the reinforcement of bridge abutments on expansive soils. Geogrids are commonly used in civil engineering projects to provide reinforcement and stability to soil structures, including bridge abutments. They help to distribute loads and reduce the potential for soil movement and settlement, particularly in areas with expansive soils that are prone to swelling and shrinking. By incorporating geogrids into the design and construction of bridge abutments, the risk of damage and failure caused by expansive soils can be minimized, ensuring the longevity and safety of the structure.

- Q:Do geogrids reduce the amount of fill material required?

- Yes, geogrids can reduce the amount of fill material required. Geogrids are used to reinforce soil and distribute loads, allowing for the construction of structures with less fill material. This can lead to cost savings and reduced environmental impact.

- Q:What are the design considerations for geogrids in mechanically stabilized earth walls?

- The design considerations for geogrids in mechanically stabilized earth walls include factors such as the strength and stiffness of the geogrid material, the type and condition of the soil being stabilized, the required wall height and slope, the anticipated load and stability requirements, and the potential for differential settlement. Other considerations include the installation and construction methods, the compatibility of the geogrid with other wall components, and any potential environmental impacts. Overall, the design of geogrids in mechanically stabilized earth walls needs to ensure adequate stability, durability, and long-term performance of the structure.

- Q:Do geogrids provide reinforcement to geosynthetic clay liners in waste containment facilities?

- Yes, geogrids can provide reinforcement to geosynthetic clay liners in waste containment facilities. Geogrids are commonly used in conjunction with geosynthetic clay liners to enhance their tensile strength and prevent their displacement. This reinforcement helps to improve the overall stability and performance of waste containment facilities.

- Q:Are geogrids resistant to temperature variations?

- Yes, geogrids are generally resistant to temperature variations. They are specifically designed to withstand a wide range of temperatures, from extreme cold to high heat, without losing their structural integrity or performance. This makes geogrids a reliable and durable solution for various engineering applications where temperature fluctuations are expected.

- Q:What are the advantages of using geogrids over traditional reinforcement methods?

- Geogrids offer several advantages over traditional reinforcement methods. Firstly, geogrids are lightweight and easy to handle, making installation faster and more efficient. Additionally, they have high tensile strength, enabling them to withstand heavy loads and distribute forces effectively. Geogrids also provide better stability and prevent soil erosion, enhancing the overall durability of structures. Moreover, they offer long-term performance and are resistant to chemical deterioration and biological degradation. Overall, geogrids offer a cost-effective and sustainable solution for soil stabilization and reinforcement compared to traditional methods.

- Q:What is the effect of installation damage on geogrid performance in long-term applications?

- Installation damage can have a significant impact on the performance of geogrids in long-term applications. Damage during installation, such as improper handling, stretching, or tearing, can reduce the structural integrity of the geogrid. This can result in decreased load-bearing capacity, reduced soil confinement, and potential failure of the geogrid system over time. It is crucial to ensure proper installation techniques and quality control measures to minimize installation damage and maintain optimal geogrid performance in long-term applications.

- Q:How much is the geogrid return

- Generally speaking, the 10-15cm should be judged according to the specification

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Geogrid Long Life High Tensile Strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords