Fiberglass Geogrids in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction

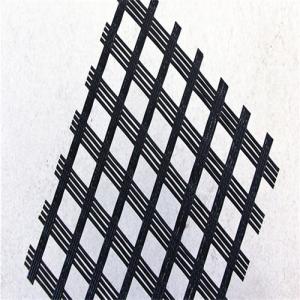

Geogrids form a distinct category of geosynthetics designed for reinforcement. These products are characterized by a relatively high tensile strength and a uniformly distributed array of large apertures (openings between the longitudinal and transverse elements). The apertures allow soil particles on either side of the installed sheet to come into direct contact, thereby increasing the interaction between the geogrid, aggregate and some soils. Also, the apertures ensure vertical drainage of a reinforced free-draining aggregate/soil.

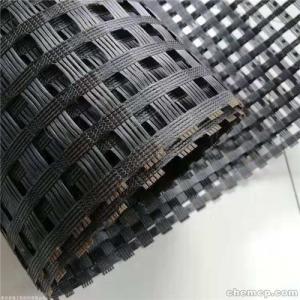

The geogrid elements vary in polymer type and cross-sectional dimensions. They can sometimes change shape and dimensions within their length. Geogrids are either integrally manufactured (punched and drawn sheets; or extruded), ultrasonically or adhesive bonded strips, or joined in a knitting or weaving process and then coated. Polymer types include polyethylene, polypropylene or high tenacity polyester that has been coated.

Although geogrids are used primarily for reinforcement, some products are designed for asphalt overlay and waterproofing or for separation and stabilization. Geogrids also are used as gabions and sheet anchors, inserted between geotextiles and geomembranes, or used to construct mattresses for fills or embankments over soft soils.Woven Geogrids are flat structures in the shape of a net made of high module synthetic fibres, that may also be coated with a further protection layer, using synthetic material (usually PVC or other polymer).

Geogrid application filled with ground material is one of the easy of soil reinforcement. The thickness of such construction may be 50% less than the thickness of standard replacement which allows avoiding costly soil replacement.

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q:What is the difference between unidirectional geogrid and two-way geogrid

- By stretching, the chain shaped molecules which are scattered in the original distribution are in a linear state, which improves the tensile strength and rigidity of the grid. In the soil, through the grid mesh and soil between the occlusion and interlock,

- Q:Panzhihua steel plastic composite geogrid manufacturers, how much money, where to sell

- It will not be affected by acid and alkali, salt solution and oil at normal temperature

- Q:How do geogrids help in the construction of embankments?

- Geogrids help in the construction of embankments by providing reinforcement and stability to the soil. They are placed within the embankment to distribute the load and prevent soil movement. Geogrids also enhance the overall strength of the embankment, reducing the risk of settlement and erosion.

- Q:Are geogrids suitable for reinforcing railway subgrades?

- Yes, geogrids are suitable for reinforcing railway subgrades. Geogrids are specifically designed to improve the stability and strength of soil and can effectively distribute loads, reduce settlement, and prevent lateral movement. They are commonly used in railway construction and maintenance projects to enhance the performance of subgrades by providing additional support and increasing load-bearing capacity.

- Q:How do geogrids help in reducing the risk of settlement of structures?

- Geogrids help in reducing the risk of settlement of structures by providing reinforcement to the soil, improving its stability and preventing excessive settlement. They distribute the load more evenly, increase the bearing capacity of the soil, and minimize the potential for differential settlement, which can cause structural damage. The geogrids effectively restrain the lateral movement of soil particles, preventing them from shifting and settling excessively, thereby ensuring the long-term stability and durability of the structures.

- Q:How do geogrids improve the performance of geotechnical structures?

- Geogrids improve the performance of geotechnical structures by enhancing their load-bearing capacity, reducing soil erosion, and providing stability. These synthetic materials are used to reinforce soil, increasing its strength and preventing it from shifting or settling. By distributing the load more evenly, geogrids minimize the potential for structural failure and improve overall stability. Additionally, they help to control soil erosion by stabilizing slopes and retaining walls, reducing the risk of landslides and erosion-related damage.

- Q:How do geogrids improve the performance of geocells?

- Geogrids improve the performance of geocells by providing additional reinforcement and stabilization. They enhance the load-bearing capacity of geocells, improve soil confinement, and prevent lateral movement and deformation. Geogrids also distribute applied loads more evenly, reducing stress on the geocell walls and increasing overall stability.

- Q:Can geogrids be used in landfills?

- Yes, geogrids can be used in landfills. Geogrids are commonly used in landfill applications to reinforce slopes, stabilize soil, and improve overall stability and performance of the landfill structure.

- Q:What is the difference between uniaxial and biaxial geogrids?

- Uniaxial geogrids have strength and stiffness in one direction, making them suitable for applications requiring reinforcement in a single direction. Biaxial geogrids, on the other hand, have strength and stiffness in two perpendicular directions, allowing for reinforcement in multiple directions. This makes biaxial geogrids more versatile and applicable to a wider range of projects.

- Q:Is there a big difference between horizontal permeability and vertical permeability coefficient

- For example, geotextile, geomembrane, soft water pipes, etc.. According to the direction of the water flow, the coefficient of permeability of the geotextile is measured

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrids in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords