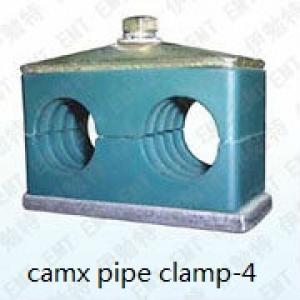

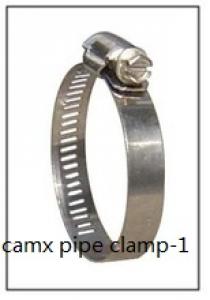

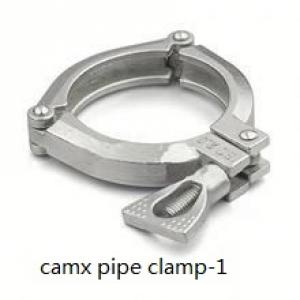

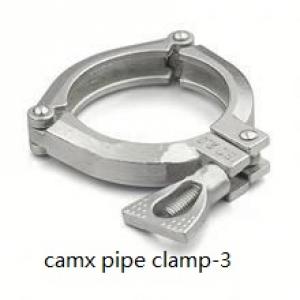

Stainless Steel Pipe Clamps

Stainless Steel Pipe Clamps Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For SaleStainless Steel Pipe Clamps Supplier & Manufacturer from China

Okorder.com is a professional Stainless Steel Pipe Clamps supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Stainless Steel Pipe Clamps firm in China.Hot Products

FAQ

- Generator carbon brush fire how to deal with?

- Carbon brush and slip ring should be inspected every day. Main inspection items are:(1) the wear length of carbon brush should not exceed 2/3. When the wear length of the carbon brush exceeds the 2/3 (i.e. the top of the carbon brush is at the same level as the top of the brush holder), it must be replaced.(2) carbon brush without sparking. When the carbon brush starts to spark, you must find out the reason and remove it in time.(3) there is no offset slip ring outside the carbon brush, and the edge of the carbon brush is not cracked.(4) the brush brush is connected with brush holder and carbon brush, without heating and touching brush holder.(5) the carbon brush has no pulsation, shaking or sticking in the brush holder.(6) regularly measure the current of each carbon brush evenly with the DC clamp type meter, and measure the carbon brush with the infrared thermometer. If abnormal, it should be replaced in time.(7) the spring pressure is normal, without deformation and fracture. Normal, the pressure on each carbon brush should be uniform and stable, the unit pressure is usually between 1.1kg ~ 2.5kg, the uneven pressure difference between the carbon brush should be less than 5%.(8) the distance between the brush holder and the slip ring conforms to the specified value. Distance between brush holder and slip ring of generator: 2.5 ~ 3 mm, distance between main brush holder and slip ring: 2~4 mm.

- Can the clamp meter measure the direct current?

- The new clamp type watches usually have DC current files, and the old-fashioned ones don't.

- How to test the 30KVA capacitor

- The capacitance is measured with a capacitor meter, and the charging and discharging test is carried out with a multimeter

- Generator carbon brush sparks, how to deal with?

- Method for treating spark of generator carbon brush1, check the length of the brush is too short to reach the lifeline, resulting in pressure is too small, the brush can not touch the slip ring;2, check the spring pressure refers to the right, if it is too small, will lead to brush discharge;3. Check the surface smoothness of the slip ring. If it is too thick, it will increase the contact resistance of the brush and cause a big spark;4, check rotor electrical, ensure normal resistance, no short-circuit between turns;5, check the bearing whether the oil gap is too large, resulting in rotor rotation, slip ring on the large number of brush, check the slip ring surface radial jump is too large. An electric spark is produced by an electric brush;6 、 and whether the brush is the same as before, the brush has a requirement for the conductive current and the friction speed.

- How to accurately measure the Ma level current

- Try a Fluke 77X Ma level process caliper table. Simple and clear.If you are going to elaborate on the principles and processes, that's a thesis.

- How to use the caliper and its working principle?

- A multimeter is a very common electrical appliance, the clamp clamp, only for the exchange of test.

- What do you mean by measuring current 2/20 and 200/600 stalls by clamp type?

- Many meters have a similar range selector.

- The reason that the phase current meter of the three-phase asynchronous motor is too low and the other two phases is normal is that it is too normal

- It can also be used to measure the faults at the far end or the proximal end of each phase. If the current balance of each phase is unbalanced, the problem of eliminating the current transformer is the problem of the motor