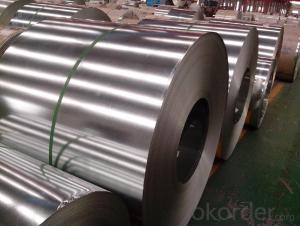

Galvanized Sheet Coil/GI Sheet/galvanized Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

deformed steel bar grade 40

material: HRB400, BS4449 GR460B

size: 8-36mmx12m.

short delivery time by bulk or container

deformed steel bar grade 40

material: HRB400, BS4449 GR460B

size: 8-36mmx12m.

short delivery time with bulk or container

packing: Mill standard export packing in bundles/coil, around 2tons/bundle.

country of Origin: China

delivery Time: Within a 35 days

Shipment: by bulk vessel or by container

Leading goods:

section steel:angles,channels,I-beam,H-beam;

coils:cold/hot rolled coils,PPGI,galvanized coils,plate,checkered plate,cutting steel plate,steel strip;

wire rod:steel wire,deformed wire,bar;

pipe:seamless pipe,rectangular pipe,welded pipe,spiral welded pipe,pipe fittings;

stainless steel:steel sheets,stainless steel strips,stainless bar,stainless tube;

special:weathering steel,shipbuilding steel;

construction steel:C-channel,Z-channel,T-bar,high-speed divider plate,corrugated steel plate,steel grating.

Advantage:

We are the spot supplier, Six huge warehouses which can hold 20,000 MT goods.

It makes the cost lower than others,we can provide the competitive price for you.

Delivery time:

Normal sizes can be provided in 7days, the others should be ready in 30---45 days.

Further treatment:

We can offer cutting,painting,drilling holes,bending,threading, welding,galvanization,packing etc.

Security interest:

We have already passed the ISO9001, BV and SGS authentication which makes the quality secured.

If you have the interest in any of the products we can provided, pls don't hesitate to connect with me. Looking forward to cooperate with you.

FAQ of Steel Deformed Bar

1. More than 10 years experience in this industry

2. 100,000 tons exporting per month

3. Professional foreign trade tea

4. OEM&ODM capacity

5. High quality assured & competitive price

6. Try our best to meet your needs & save your budget

7. Very popular in Southeast Asia, Africa, Mid-East and South America etc.

8. VIP membership system, first time customers and long-term cooperation customers can get extra discount on some products.

Cold-rolled stainless steel sheet hot-rolled coil is crude and rolled under low temperature conditions. Because there will be no high-temperature processing, for this procedure in the production process, so people often referred to as its cold-rolled steel. Higher than the hardness of cold-rolled steel hot-rolled, cold-rolled stainless steel sheet so the texture is hard, not suitable for a large number of deep-processing.

In accordance with the organizational characteristics of steel

In accordance with the organizational characteristics of stainless steel sheet to divide, then we would more complicated than in accordance with the production process to divide. But they can be roughly divided into five categories, namely: austenitic sheet, plate ferritic, austenitic - ferritic sheet, plate martensitic precipitation hardening stainless steel sheet plate these five categories. Here we will highlight five categories of stainless steel sheet own characteristics.

Austenitic stainless steel sheet contains chromium, a small amount of molybdenum, titanium, nickel and other elements, so that the hardness and plasticity are high, life is widely used.

The amount of chromium-containing ferritic stainless steel sheet is about twice as austenitic. Thus, the ferritic stainless steel sheet hardness, corrosion resistance, anti-oxidation properties better than austenitic stainless steel sheet, but its disadvantage is poor machinability, commonly used as some special parts production.

Austenitic - ferritic stainless steel sheet is compatible with austenitic - ferritic stainless steel plate advantages, a variety of performances are relatively good, and life applications are particularly widespread.

- Q:How do steel sheets compare to other materials in terms of durability?

- Compared to other materials, steel sheets are widely acknowledged for their exceptional durability. The long-lasting nature of steel can be attributed to its unique qualities, including high tensile strength and resistance to corrosion. Unlike wood or plastic, steel sheets are not easily susceptible to wear and tear, making them the preferred choice for various applications that require durability. Construction projects, automotive manufacturing, and industrial applications all benefit from the ability of steel sheets to withstand heavy loads without bending or warping. Furthermore, steel sheets have a longer lifespan than other materials, reducing the need for frequent replacements and maintenance. In summary, the durability of steel sheets is unparalleled, making them a dependable and cost-effective option for many industries.

- Q:What are the limitations of using steel sheets?

- The use of steel sheets in various applications comes with several limitations. To begin with, steel sheets are considerably heavy compared to other materials, which can present challenges in terms of transportation and installation. This weight can also hinder their usage in industries like aerospace or automotive, where weight reduction is crucial. Secondly, steel sheets are prone to corrosion, particularly when exposed to moisture and chemicals. Without proper protection, this can lead to rusting and a decrease in structural integrity over time. Therefore, additional coatings or treatments are often necessary to prevent corrosion, which adds to the overall cost and maintenance requirements of using steel sheets. Another limitation is the limited flexibility of steel sheets, making it difficult to mold or shape them into complex forms. This restricts their application in areas where intricate designs or curved surfaces are needed, such as the construction of curved roofs or architectural structures. Furthermore, steel sheets have poor thermal insulation properties, meaning they conduct heat and cold more readily than other materials. This can result in temperature fluctuations and energy loss in buildings, necessitating additional insulation measures to maintain thermal comfort and energy efficiency. Lastly, steel sheets are a finite resource, and their production has a significant environmental impact. The extraction of raw materials, energy consumption, and carbon emissions associated with steel production make it less sustainable compared to alternative materials. In conclusion, while steel sheets are widely valued for their strength and durability, it is important to consider their limitations, including their weight, susceptibility to corrosion, limited flexibility, poor thermal insulation properties, and environmental impact, when selecting materials for specific applications.

- Q:Can steel sheets be used for structural purposes?

- Yes, steel sheets can be used for structural purposes. Steel sheets are commonly used in construction and engineering projects to provide strength and support to various structures such as buildings, bridges, and infrastructure. The high tensile strength and durability of steel make it an ideal material for structural applications.

- Q:What are the different joining methods for steel sheets?

- There are several different methods for joining steel sheets, each with its own advantages and applications. 1. Welding: Welding is one of the most common methods used to join steel sheets. It involves melting and fusing the edges of the sheets together using heat. There are various welding techniques such as arc welding, MIG welding, TIG welding, and spot welding. Welding offers strong and durable joints, but it requires skilled operators and can be time-consuming. 2. Bolting: Bolting involves using bolts or screws to connect steel sheets. This method is commonly used when disassembly or maintenance is required. Bolting provides a strong and reliable joint, and it is relatively simple and quick to perform. However, it may require drilling holes in the sheets and can result in a less aesthetically pleasing appearance compared to welding. 3. Riveting: Riveting is a method that uses metal pins or rivets to join steel sheets together. The rivets are inserted through pre-drilled holes in the sheets and then deformed or expanded to hold them in place. Riveting offers strong and secure joints, and it is often used in applications that require high shear strength. However, it can be time-consuming and requires specialized tools and skills. 4. Adhesive bonding: Adhesive bonding involves using specialized adhesives or bonding agents to join steel sheets together. The adhesive is applied between the sheets, and it forms a strong bond as it cures. This method offers excellent aesthetics as it leaves no visible joints, and it can also distribute stress evenly across the joint. Adhesive bonding is commonly used in industries where welding or other methods are not suitable, such as in the automotive and aerospace sectors. 5. Clinching: Clinching is a method that uses mechanical force to join steel sheets together. It involves deforming the edges of the sheets to interlock them and create a strong joint. Clinching does not require any additional materials such as fasteners or adhesives, making it cost-effective. However, it may not be suitable for applications that require high load-bearing capacity. Overall, the choice of joining method for steel sheets depends on factors such as the application, desired strength, aesthetics, time constraints, and cost considerations. Each method has its own advantages and limitations, and it is important to select the most appropriate method for the specific requirements of the project.

- Q:What is the thickness of the steel sheets?

- The thickness of the steel sheets can vary depending on the specific application and requirements. Common thicknesses for steel sheets range from 0.4 millimeters to several inches, with standard measurements including 0.5 mm, 1.0 mm, 1.5 mm, 2.0 mm, 2.5 mm, and so on. However, it is important to note that the thickness can be customized based on the intended use, such as for construction, manufacturing, or automotive purposes. Therefore, it is essential to consult the specifications or inquire with the manufacturer or supplier to determine the exact thickness of the steel sheets in question.

- Q:What are the bending and forming capabilities of steel sheets?

- Steel sheets have excellent bending and forming capabilities due to their inherent strength and malleability. They can be easily shaped into various forms, such as curves, angles, and complex geometries, through processes like bending, rolling, and stamping. This versatility makes steel sheets widely used in industries such as construction, automotive, and manufacturing.

- Q:What's the difference between single rolling steel sheet and continuous rolling steel plate?

- Single rolled steel plate usually refers to medium plate, in the process of rolling and finishing, the plate has been flat, usually thicker (6mm or more), the width of the fastest up to 4800mm.

- Q:Are the steel sheets perforated or solid?

- The steel sheets are perforated.

- Q:Can steel sheets be used for mezzanine flooring?

- Yes, steel sheets can be used for mezzanine flooring. Steel sheets offer several advantages for mezzanine flooring, including their strength, durability, and versatility. Steel sheets are able to withstand heavy loads and provide a stable and reliable flooring solution. Additionally, they can be easily customized to fit specific dimensions and requirements, making them adaptable for different mezzanine designs. Steel sheets are also resistant to fire, moisture, and pests, ensuring a long-lasting and low-maintenance flooring option. Overall, steel sheets are a popular choice for mezzanine flooring due to their strength, durability, and flexibility.

- Q:Can steel sheets be used in the construction of bridges?

- Indeed, the utilization of steel sheets in the construction of bridges is possible. Due to its numerous beneficial characteristics, steel has become a prevalent material in bridge construction. Owing to their exceptional strength and durability, steel sheets are well-suited for enduring substantial loads and adverse weather conditions. Furthermore, their flexibility facilitates simpler fabrication and installation processes. Moreover, the ease with which steel sheets can be welded or bolted together makes them highly suitable for the construction of expansive structures such as bridges. In conclusion, steel sheets provide a dependable and cost-effective solution for bridge construction.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Sheet Coil/GI Sheet/galvanized Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords