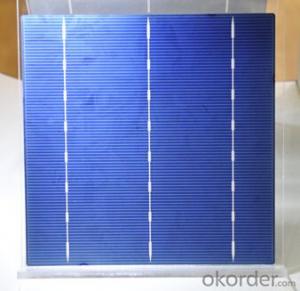

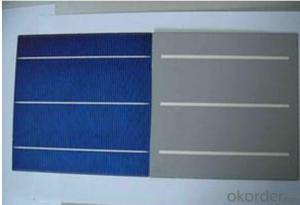

Perc Silicon Solar Cells

Perc Silicon Solar Cells Related Searches

Solar Panel Inverter For Rv Solar Panel Kit With Inverter Inverter Used In Solar Panel Best Inverter Solar Panel Solar Panel On Roof Rack Solar Panel To 240v Inverter Solar Panel To Inverter Ratio Solar Panel Mini Inverter Solar Panel Inverter Battery Solar Panel Inverter BoxHot Searches

Cheap Solar Cells For Sale Flexible Solar Cells For Sale Printed Solar Cells For Sale Bulk Solar Cells For Sale 6x6 Solar Cells For Sale Broken Solar Cells For Sale Cpv Solar Cells For Sale Price Of Silicon Solar Cells Price Of Solar Cells Over Time Buy Solar Cells From China Cheap Solar Cells China Best Type Of Solar Cells Flexible Solar Cells Price 3 Types Of Solar Cells Production Of Solar Cells Common Types Of Solar Cells Q Cells Solar Panel Prices Home Depot Solar Cells N-Type Solar Cells Buy Solar Cells WholesalePerc Silicon Solar Cells Supplier & Manufacturer from China

Okorder.com is a professional Perc Silicon Solar Cells supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Perc Silicon Solar Cells firm in China.Hot Products

FAQ

- Yes, solar cells can be used for portable devices. They are commonly used in small electronic gadgets such as smartphones, tablets, and portable chargers to harness solar energy and convert it into electrical power. This enables the devices to be charged or powered by sunlight, making them convenient and environmentally-friendly options for on-the-go usage.

- Solar cells have a positive impact on water resources as they do not require water for their operation, unlike other forms of energy generation such as fossil fuel power plants. This reduces the strain on water resources and helps conserve water for other important uses.

- What is the working principle of a solar cell?

- The simplest way to explain this is : A solar cell converts the sun's energy into electricity.

- Solar cells perform well in high-altitude locations due to several factors. Firstly, at higher altitudes, there is less atmospheric interference such as dust, pollution, and cloud cover, which allows for a more direct and intense sunlight exposure. This leads to increased solar energy absorption and higher power output from the solar cells. Additionally, the thinner atmosphere at high altitudes reduces the scattering of sunlight, resulting in improved efficiency of solar cells. Therefore, solar cells can be highly efficient and productive in high-altitude locations, making them an ideal renewable energy solution in such areas.

- What is the pollution of solar cells?

- dry batteries and alkaline batteries to dry batteries and batteries, for example, to study its composition. We use spare time to open a piece of carbon zinc battery and found that the surface is made of zinc cylinder (according to the information that, in order to increase the toughness of zinc sheet strength, slow down the corrosion of zinc film to extend battery life, In the addition of aluminum,

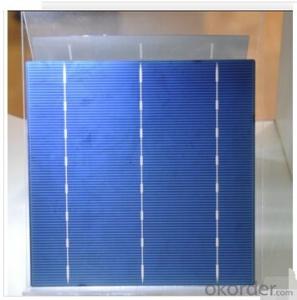

- Solar cells are typically made using a process called photovoltaic manufacturing, which involves several steps. First, silicon, which is the main material used in solar cells, is extracted from silica, a component of sand. The extracted silicon is then purified and transformed into a crystal structure suitable for solar cell production. These silicon wafers are then cut into thin slices. Next, various layers of conductive materials and anti-reflective coatings are applied to the wafer, creating the necessary electrical properties and enhancing light absorption. Finally, electrical contacts are added to the cell, allowing the generated electricity to be collected and used.