Hdpe Granules Inc

Hdpe Granules Inc Related Searches

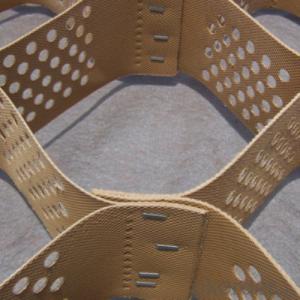

Geomembrana In Hdpe White Plastic Sun Loungers Uv Coated Polycarbonate Panels Bopp Film 100 Microns Geomembrana Hdpe 2 Mm Precio Fruit Foam Net Hdpe Membrane 40 Mil Hdpe Liner Second Hand Sun Loungers Hdpe GeogridHot Searches

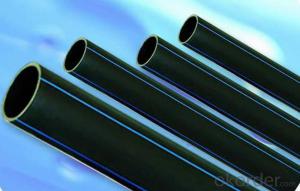

China Pvc Geomembrane China Geomembrane Roll Sheet Hdpe Geomembrane Sheet Price Hdpe Geomembrane China China Geomembrane Geomembrane China Hdpe Geomembrane Price Geomembrane Liner Price Geomembrane Price Cost To Waterproof A Basement Waterproof Plywood Cost Waterproof Mdf Suppliers Wholesale Hdpe Geomembrane Roll Geomembrane Factory Wholesale Liner Hdpe Geomembrane Wholesale Geomembrane Hdpe Wholesale Hdpe Geomembrane Geotextile Membrane Suppliers Geomembrane Market Size Geomembrane For SaleHdpe Granules Inc Supplier & Manufacturer from China

Okorder.com is a professional Hdpe Granules Inc supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Hdpe Granules Inc firm in China.Hot Products

FAQ

- What plastic material has great impact resistance?

- The ability of metal materials, machinery parts and components to resist impact damage is called impact strength.

- What are the raw materials of foam plastics and how do they come out?

- The foaming agents for epoxy resins are two types: physical foaming agents and chemical foaming agents. Physical foaming agents are mainly low boiling liquid, such as three chloro methane (F11), three chlorine, three fluorine ethane (F112), two chlorine, two fluorine methane (F12) and so on. By using the curing heat of the epoxy resin, the liquid with low boiling point is evaporated, and the gas is released, and the products are small in density and low in thermal conductivity. But fluorine hydrocarbons have a damaging effect on the atmosphere and are often used to spray foaming processes. According to the experts of China epoxy resin industry association, toluene and so on can be used as auxiliary foaming agent. In addition to foaming, it also acts as a curing reaction, a heat absorber and a diluent.

- What is the essential difference between plastic raw materials and engineering plastics?

- Engineering plastics generally have many properties that are not common in plastics. They are often used in construction machinery to replace certain metals.Plastic is resin and filler, so it is usually granular. Raw materials too. Only a few powdery.

- How about the price of plastic raw materials now?

- Businesses still adhere to prudent operation, mainly with quotations in the market, and more wait-and-see mentality.

- Plastic raw materials, electroplating grade round face, electroplating grade, what is the concept?

- The so-called plastic raw material electroplating grade means that the particle of the plastic material is high in purity and high in polarity, and is easy to be evenly adhered to the metal particles before the plating.

- What are the raw materials for vest plastic bags?

- Shrink film (Shrinkfilm) is a thermoplastic film that is stretched in production, directed, and contracted by hot air treatment or infrared radiation during use. After heat treatment, the film is wrapped tightly in the package, and the shrinkage force reaches the maximum value in the cooling stage and can be stored for a long time.

- What are the raw materials needed for making plastic bags?

- In addition, the bag color and performance requirements are not high, you can choose recycled polyethylene. Plastic can be recycled, because of the repeated use of processing, non-toxic, tasteless new plastic become cloudy, less than the original hygiene and color requirements. But this plastic bag is made from recycled material, which is environmentally friendly, and the price is 10% to 50% lower than that of the new material bag

- How to test plastic raw materials?

- Thermal stability test of size and appearance quality. Place the product in a 8020C oven, 24H, and cool down to 2350C (2H). Measure the size of the same measuring point before and after the test, and calculate the percentage change rate. And observe the appearance quality changes, dimensional change rate of <0.2%, appearance is not allowed to have deformation, crack, expansion, surface gray, discoloration and other phenomena.