HDPE Pond Liner Geomembrane Manufacturer Black Lining

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of HDPE Pond Liner Geomembrane Manufacturer Black Lining

1) Thickness:0.15-4.0mm

2) Width:1m-8m

3) Certificate:CE/ISO9001,14001

4) Long life,best price,fast delivery

HDPE Pond Liner Geomembrane Manufacturer Black Lining specifications

1) Thickness : 0.15mm - 4.0mm.

2) Width : Within 8 m (1m-8m).

3) Length : 50m-100m/roll (as request).

4) Material : HDPE,( LDPE, LLDPE, PVC, EVA ).

5) Color : Black , white , red , blue , or as required.

6) Optional surface : Textued(one or two side) or smooth surface.

7) The biggest geomembrane liner manufacturer/factory in China for many years .

HDPE Pond Liner Geomembrane Manufacturer Black Lining Features

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

HDPE Pond Liner Geomembrane Manufacturer Black Lining Applications:

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

Packaging & Delivery

| Packaging Details: | Packing into roll in PP woven bags |

| Delivery Detail: | within 2 weeks after receiving the 30% deposit |

HDPE Pond Liner Geomembrane Manufacturer Black Lining technical index

No. | Item | Test Value | ||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | ||

1 | Minimum Density(g/cm³) | 0.939 | ||||||

2

| Tensile Property | |||||||

Strength at yield,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

Strength at break ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

Elongation at yield,% | 12 | |||||||

Elongation at break,% | 700 | |||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

5 | Stress Crack Resistance, hrs | 300 | ||||||

6 | Carbon Black Content, % | 2.0-3.0 | ||||||

Carbon Black Dispersion | 1 or 2 | |||||||

7 | Standard OTI Min | 100 | ||||||

High Pressure OTI Min | 400 | |||||||

8 | Impact Cold Crack at -70°C | Pass | ||||||

9 | Water vapor permeability (gNaN/cm2 .s.Pa) | ≤1.0×10-13 | ||||||

10 | Dimensional Stability (%) | ±2 | ||||||

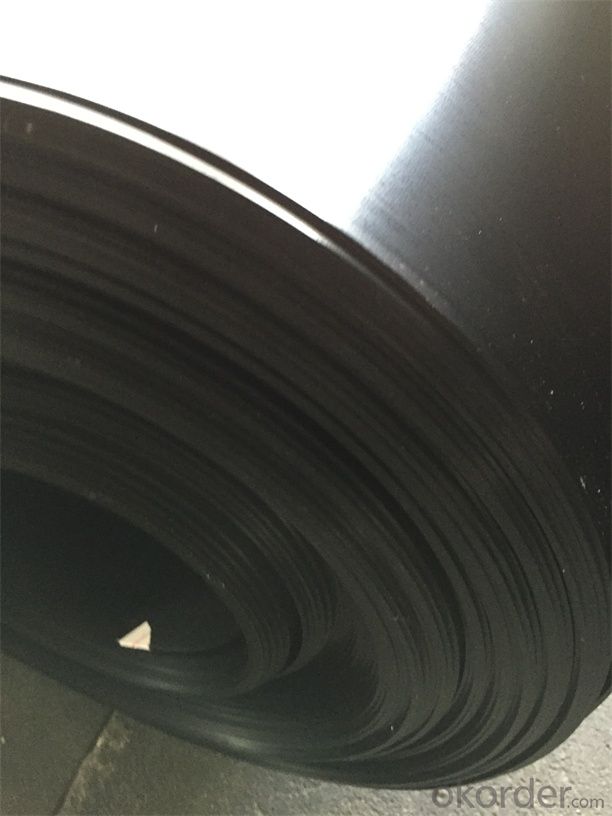

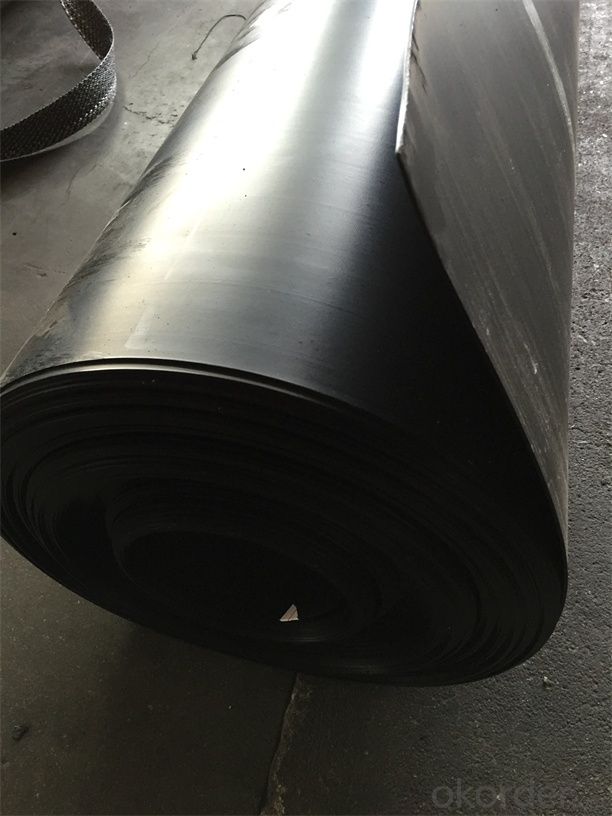

Gemembrane Show:

FAQ:

- Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

HDPE Geomembrane Price

- Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

- Q3:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

- Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

- Q:Are geomembranes suitable for use in hydroelectric power plants?

- Yes, geomembranes are suitable for use in hydroelectric power plants. They are commonly used in various applications within hydroelectric power plants, such as lining reservoirs and canals, preventing seepage and leakage of water, and protecting the surrounding environment. Geomembranes provide an effective barrier against water, chemicals, and contaminants, making them a reliable solution for ensuring the integrity and efficiency of hydroelectric power plants.

- Q:What are the limitations of geomembranes in high-pressure applications?

- One limitation of geomembranes in high-pressure applications is their susceptibility to punctures or tears. The increased pressure can create stress points on the geomembrane, making it more prone to damage. Additionally, geomembranes may have lower tensile strength and elongation properties, which could further contribute to their vulnerability under high-pressure conditions. It is essential to carefully consider the design and materials used when using geomembranes in high-pressure applications to ensure they can withstand the specific demands and avoid potential failures.

- Q:How much degree can high-density hdpe geomembrane withstand?

- geomembrane produced in standard will absorb heat under sun, up to 50- 60 degrees. The average temperature tolerance is at about 70 degrees. Heat tolerant geomembrane made by new technology can operate at 100 degrees.

- Q:Can geomembranes be used in hydraulic applications?

- Yes, geomembranes can be used in hydraulic applications. They are often used as liners or barriers to provide containment and prevent seepage in various hydraulic structures such as canals, reservoirs, ponds, and dams. Geomembranes are chosen for their impermeable properties, durability, and resistance to chemicals, making them reliable for hydraulic applications.

- Q:Preparation of composite geomembrane precautions?

- (1) the use of buried must be used: cover thickness should not be less than 30cm (2) refurbishment system should be anti-seepage system: cushion, impermeable layer, the transition layer, the protective layer of the composition of the composite geomembrane The (3) soil to be solid, to avoid uneven subsidence, cracks, anti-seepage within the turf, root to clear. And the surface of the membrane with a small particle size of sand or clay as a protective layer. (4) laying the geomembrane do not pull too tight, both ends of the soil into the corrugated part of the soil is better, especially with the rigid material anchoring, should leave a certain amount of expansion and contraction. (5) construction, should avoid the stones, heavy objects directly hit the geomembrane, the best side of the construction, while laying the film, while covering the protective layer. Annangh /

- Q:does the skylight of the car stick membrane?

- We generally not recommend sticking membrane on the car skylight. 1, there have no too much infrared and ultraviolet radiation to the inside of the vehicle through the skylight; 2, usually there is no need to insulate heat through the glass skylight; 3, after window sticking membrane, it will increase the glass thickness, if the construction is not good, it will easily lead to the switch not smooth.

- Q:How do geomembranes contribute to oil and gas containment?

- Geomembranes are impermeable barriers made of synthetic materials that are used to contain and prevent the leakage of fluids, including oil and gas. These membranes are specifically designed to provide a reliable and durable solution for storing and transporting oil and gas by creating a strong barrier that prevents any release or seepage of the stored fluids. By effectively containing oil and gas, geomembranes help to minimize the risk of environmental contamination and ensure the safe and efficient handling of these valuable resources.

- Q:What are the design considerations for geomembranes in floating covers?

- Some design considerations for geomembranes in floating covers include selecting the appropriate material based on factors like chemical resistance and UV stability, ensuring proper thickness to withstand potential punctures or tears, considering the potential for settlement or deformation of the underlying soil or substrate, determining the required anchoring or ballasting system to keep the cover in place, and considering the potential for wind or wave action and its impact on the cover's performance.

- Q:Can geomembranes be used in gas barrier applications?

- Yes, geomembranes can be used in gas barrier applications. They are commonly used to prevent the migration of gases such as methane, radon, and volatile organic compounds (VOCs) in various industries including landfill sites, mining operations, and wastewater treatment plants. Geomembranes act as a barrier, preventing the gases from escaping into the surrounding environment and potentially causing harm.

- Q:How do geomembranes contribute to landfill leachate collection?

- Geomembranes are impermeable barriers that are used to line the base and sides of landfills. They play a crucial role in landfill leachate collection by preventing the leachate from seeping into the surrounding soil and groundwater. The geomembrane acts as a barrier, effectively containing the leachate within the landfill, allowing it to be collected and properly managed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Pond Liner Geomembrane Manufacturer Black Lining

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords