Irradiation Cross-linkable Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High temperature resistive, irradiation cross-linkable, flame retardant POE compound

1. Type and application

Type | Product | Application and Cable Specification |

FJZ1125H | 125℃Irradiation cross-linkable, flame retardant POE compound | Used for cross-linked wires of apparatus and instruments, electric motor and etc. Pass UL3271 standard. Meeting RoHs standard |

FJZ2125H | 125℃Irradiation cross-linkable, flame retardant POE compound | Used for cross-linked wires of apparatus and instruments, lamps and lanterns and etc. Meeting RoHs standard |

FJZ1135H | 135℃Irradiation cross-linkable, flame retardant POE compound | Used for cross-linked and insulating wires and cables of apparatus and instruments, equipments and etc. Meeting RoHs standard |

FJZ1150H | 150℃Irradiation cross-linkable, flame retardant POE compound | Same above, and pass the 38 grade standard of UL1581. Meeting RoHs standard |

2. Product description

Irradiation cross-linkable POE compound, based on POE resin, is produced and pelletized by special technology with adding special stabilizing agent, modifier, flame retardant, cross-linking agent and other special additives.

3. Processing

The compound can be processed with conventional extruders, and the screw with a minimum 20:1 L/D and low compression ratio die is recommended. Low tensile ratio is needed.

following temperature(℃) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

temperature ℃ | 140 | 145 | 150 | 155 | 150 | 150 |

4. Storage and transport

Packaging:25kg/bag, PE membrane inside bag and Kraft outside bag.

Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be in clean, cool, dry, and ventilated conditions.

5. irradiated dosage

The normal irradiated dosage(recommended) of irradiation cross-linked and flame retardant POE compound is 15 megarad.

6. Properties

Table

Item | Unit | FJZ1125H | FJZ2125H | FJZ1135H | FJZ1150H | ||||

Standard | Typical | Standard | Typical | Standard | Typical | Standard | Typical | ||

Density | g/cm3 | -- | 1.34 | -- | 1.30 | -- | 1.33 | -- | 1.32 |

Hardness | ShoreA | -- | 91 | -- | 95 | -- | 92 | -- | 92 |

Tensile Strength | ≥ MPa | 12.5 | 14.0 | 12.5 | 16.0 | 12.5 | 15.0 | 13.8 | 16.0 |

Elongation at Break | ≥ % | 200 | 350 | 200 | 360 | 200 | 380 | 300 | 400 |

Impact Brittleness Temperature | ≤ ℃ | -25 | Pass | -25 | Pass | -25 | Pass | -25 | Pass |

Volume Resistivity, at 20℃ | ≥Ω﹒m | 1.0×1012 | 2.0×1013 | 1.0×1012 | 3.0×1013 | 1.0×1012 | 2.0×1013 | 1.0×1012 | 3.0×1013 |

Dielectric Strength | ≥MV/m | 20 | 24 | 20 | 25 | 25 | 25 | 25 | 25 |

Oxygen Index | ≥ | 30 | 30 | 27 | 28 | 27 | 27 | 27 | 27 |

Thermal Prolongation |

|

|

|

|

|

|

|

|

|

Elongation Under Load | ≤ % | 100 | 20 | 100 | 25 | 100 | 25 | 100 | 25 |

Permanent Elongation after cooling | ≤ % | 10 | 0 | 10 | 5 | 10 | 5 | 10 | 0 |

Thermal Aging |

|

|

|

|

|

|

|

|

|

Aging Temperature | ℃ | 158±2 | 158±2 | 158±2 | 158±2 | 165±2 | 165±2 | 180±2 | 180±2 |

Aging Time | h | 168 | 168 | 168 | 168 | 168 | 168 | 168 | 168 |

Variation on Tensile Strength | ≥ % | 80 | 103 | 80 | 102 | 80 | 107 | 80 | 110 |

Variation on Elongation at Break | ≥ % | 80 | 98 | 80 | 97 | 80 | 90 | 80 | 86 |

The above data are all the properties of compound after cross-linked.

7. Company

- Q:Is the plastic with high melting index good?

- It was established by the American Society for measurement standards (ASTM), a method used to identify plastic properties, according to the DuPont Co (DuPont).

- Q:I do PA, PC, PP and other plastic raw materials can be used in the eye frame and lens it

- In general, the lenses of PC need to be covered with scratch resistant protective films, which will be sufficient for better aging, and most lenses for children.

- Q:Low pressure plastic raw materials in the process of blowing the two sides of the fold, how to deal with?

- The blowing ratio is one of the control points of blown film production and! Refers to the ratio between the bubble diameter and the diameter of not blowing blowing after.

- Q:What are the raw materials for producing plastic films?

- Plastic film raw materials are: PVC, polyethylene, polypropylene, polystyrene and other resins.

- Q:What are the plastic bags made of?

- General civilian products, mostly polyethylene (PE) to do, PE is divided into low pressure high-density HDPE, low pressure high-density LDPE and linear low-density LLDPE

- Q:Will plastic raw materials (such as PET, PP, etc.) be made of non-woven fabrics, will certainly contain BPA?

- BPA is an additive, and plastic products are usually added! If it is a recycled PP material, the genus will contain

- Q:What kind of plastic material is used for medical instruments?

- According to the use requirements of medical plastics, it is often necessary to make products with surface hydrophilicity, anti coagulation, radiation sterilization and other special functions.

- Q:Main ingredients and formulations of PPR tubes

- PP-R (polypropylene, random) tubes are also called type three polypropylene tubes and also called random copolymerized polypropylene tubes or PPR tubes. The main component is polypropylene three. The formula is different for each manufacturer. This ratio requires manufacturers to do experiments many times before they can be certain.

- Q:What is the difference between ABS plastic raw materials and recycled materials? Or how to distinguish between raw materials and recycled materials?

- 1. recycled material is not natural (ABS is yellow).2. non black pellets with black spots are recycled.3. the impurity in the aggregate is the recycled material.4. of the voids in the pellets are recycled.5. do MFI test, the result is more than 10% of indicators are recycled material.6., feed heating, smell, smoke, melting temperature is low, fast flow is recycled material.

- Q:What type of raw material for plastic straw?

- The main component of plastics is resin. The term was first resin secrete by animal and plant lipid and its name, such as rosin, shellac, resin is not mixed with various additives and polymer compounds. Resin accounts for about 40% to 100% of the total weight of plastics.

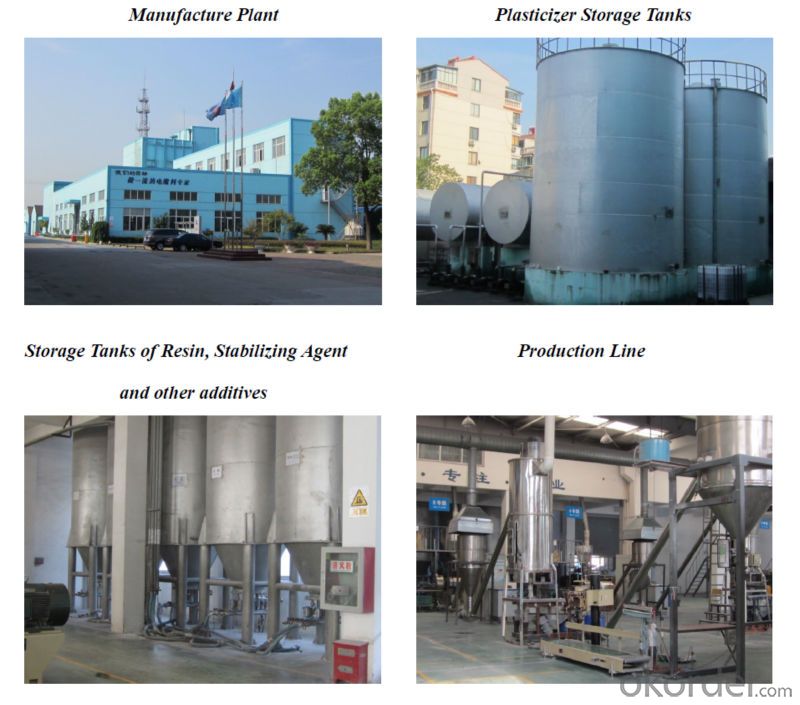

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Irradiation Cross-linkable Flame Retardant Polyolefin Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords