Geomembrane HDPE for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomembrane HDPE for Architectural Engineering

Description Of Geomembrane HDPE for Architectural Engineering

Geomembrane, also known as water-proof plate, is made from polymer materials like polyethylene, through blow molding.

Main Features of Geomembrane HDPE for Architectural Engineering

By its raw materials - molecular structure, Polyethylene (PE) geomembrane is divided into low-density polyethylene (LDPE) geomembrane, linear low density polyethylene (LLDPE) geomembrane, high-density polyethylene (HDPE) geomembrane;Aside from colorless and transparent raw material, you can made it into the black, green, blue, yellow, etc by adding different color masterbatch., also made into geomembrane with the black front and the blue back or other 2 different colors as required by customers.

Applications of Geomembrane HDPE for Architectural Engineering

1. HDPE geomembrane is applicable to environmental protection and sanitation: such as landfill, sewage treatment plant, power plant adjustive pool, industrial, hospital solid waste;

2. HDPE geomembrane is applicable to hydraulic engineering: such as seepage control, plugging, reinforcement for rivers, lakes and reservoirs and dams, drainage seepage control, vertical core wall, slope protection, etc.

3. HDPE geomembrane's applications in municipal engineering: subway, underground works of the building, planting roof, roof garden, sewage pipe seepage control;

4. Polyethylene impermeable membrane is applicable to the garden: artificial lake, river, reservoir, golf course pond bottom, slope, green lawn waterproofing and damp-proofing;

5. High density polyethylene geomembrane is applicable to petrochemical industry: chemical plant, oil refinery, storage tank seepage control, chemical reaction cell, lining and secondary lining for sedimentation tank, etc.

6. Polyethylene geomembrane is applicable to mining: washing pool, soaking pool, the ash-field, dissolving pool, settling pool, yard, tailings substrates seepage control;

7. Low density polyethylene geomembrane for transport facilities: foundation reinforcement for the road, culvert seepage control;

8. HDPE geomembrane is applicable to agriculture: seepage control for reservoir, drinking water pool, water storage pond, irrigation system;

9. HDPE geomembrane is applicable to aquaculture industry: the lining of intensive factory farming ponds, fish ponds, shrimp ponds, the sea cucumber ring slope protection, etc;

10. HDPE geomembrane is applicable to Salt industry: saltworks crystalline pool, brine pool thatch cover, salt membrane, the salt pool plastic sheet membrane.

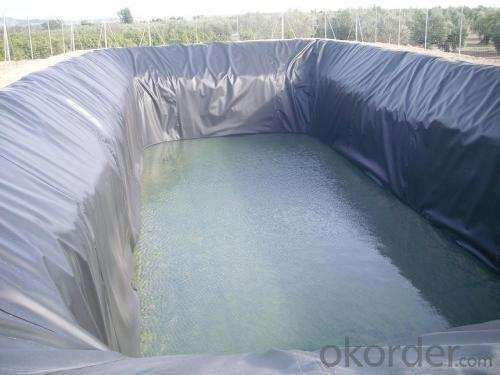

IMages of Geomembrane HDPE for Architectural Engineering

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q:What are the considerations for geomembrane welding techniques?

- Some considerations for geomembrane welding techniques include the type and thickness of the geomembrane material, the desired strength and durability of the weld, the environmental conditions during welding (such as temperature and humidity), the skill and experience of the welder, and the specific project requirements and regulations. It is important to ensure proper equipment, adequate preparation and cleaning of the geomembrane surfaces, and adherence to industry standards and best practices to achieve a successful and long-lasting weld.

- Q:the seepage-proof pavement of composite geomembrane.

- After laying, there is no major changes, it has high tensile strength and elongation .9m, paving, two cloth one film. after waving and combination.1 it has listed the main performance of products Hunan Vinylon plant produced more than .5 indicators. ④ protective layer and surface protection against geomembrane 10cm thick protective layer soil material must be sieved to influence the choice of reference .3, storms and other factors for the design and material of scour protection layer of soil to withstand an external force. Domestic and international application of impermeable plastic film. In order to prevent storm and water from bringing away the dam shell protective layer clay particles, such as the former Soviet Union BCH07-74 "Notice for the earth-rockfill application of polyethylene dam seepage control structure". Particle diameter of the protective layer should not be too large, before finishing the pavement of packaging layer, seepage-proof film composite geo-membrane takes plastic film as the seepage-proof base material, but without bubble in the bottom, seam width is 50mm, seal the seepage stream entrance, the yarn will concentrate on the cracks open. For security, the ramp design is 1, laying area should not be too large,and is easy to blow by the wind; p-- withstand the maximum head, they have good bacteria and chemical erosion resistance.

- Q:How do geomembranes contribute to erosion control in riverbanks?

- Geomembranes are impermeable liners made of synthetic materials that are used to prevent water seepage and erosion in riverbanks. They act as a barrier between the soil and water, effectively reducing the impact of flowing water on the riverbank. By preventing water from infiltrating the soil, geomembranes protect the stability and integrity of the riverbank, minimizing erosion and reducing the risk of landslides or collapses. Additionally, geomembranes also help to control the flow of water, redirecting it away from vulnerable areas and preventing concentrated flows that can accelerate erosion. Overall, the use of geomembranes in riverbanks plays a crucial role in erosion control by providing effective protection against the erosive forces of water.

- Q:What are the advantages of using geomembranes in industrial wastewater treatment?

- There are several advantages of using geomembranes in industrial wastewater treatment. Firstly, geomembranes act as a barrier, preventing the contamination of soil and groundwater by containing the wastewater. This helps to protect the environment and ensure compliance with regulations. Secondly, geomembranes are highly resistant to chemical degradation, making them ideal for handling and treating industrial wastewater that may contain hazardous substances. They provide a reliable and durable solution for containing and treating wastewater in harsh industrial environments. Furthermore, geomembranes offer flexibility in design and installation, allowing for customization to fit specific site requirements. They can be easily fabricated into different shapes and sizes, ensuring an efficient and effective wastewater treatment system. Additionally, geomembranes have low maintenance requirements and a long lifespan, reducing operational costs over time. They are also relatively easy to install and repair, minimizing downtime and ensuring continuous wastewater treatment operations. Lastly, the use of geomembranes in industrial wastewater treatment helps to improve overall efficiency by facilitating the separation of contaminants from water. This leads to cleaner water for reuse or discharge, contributing to water conservation and sustainable practices. In summary, the advantages of using geomembranes in industrial wastewater treatment include environmental protection, chemical resistance, flexibility, low maintenance, and improved efficiency.

- Q:What are the requirements for geomembranes used in aquaculture ponds?

- The requirements for geomembranes used in aquaculture ponds include being highly durable and resistant to punctures and tears, being chemically inert to ensure compatibility with water and aquatic life, having low permeability to prevent leakage of water and chemicals, being UV resistant to withstand prolonged exposure to sunlight, being easy to install and repair, and meeting any specific regulations or standards set by local authorities.

- Q:What are the prospects of electrothermal?film?

- Electrothermal film has been in the market for at least ten years. Currently the biggest problem is the large power consumption, even if you can cover the electric charge,original home wire diameters restrict the use of high-power electrical appliances. Another problem is power attenuation, the other problem is breaker tripping caused by electric leakage.

- Q:How do geomembranes prevent water seepage in fishponds?

- Geomembranes prevent water seepage in fishponds by acting as a barrier or lining that prevents water from leaking out of the pond. They are made of impermeable materials, such as high-density polyethylene (HDPE), which do not allow water to pass through. The geomembrane is installed beneath the pond substrate to create a watertight seal, ensuring that the water remains contained within the fishpond and minimizing the risk of seepage.

- Q:What are the advantages of using geomembranes in hazardous waste containment?

- There are several advantages of using geomembranes in hazardous waste containment. Firstly, geomembranes are impermeable, meaning they prevent the migration of hazardous materials into the surrounding environment, reducing the risk of contamination. Secondly, they are highly durable and resistant to degradation, ensuring long-term protection for the waste and minimizing the need for maintenance or replacement. Additionally, geomembranes are flexible and can conform to the shape of the containment area, allowing for more efficient and cost-effective construction. Lastly, these liners are compatible with various waste types, making them versatile for different hazardous waste containment applications.

- Q:Can geomembranes be used in decorative ponds and water features?

- Yes, geomembranes can be used in decorative ponds and water features. Geomembranes are impermeable liners that prevent water from seeping into the ground, making them an excellent choice for creating and maintaining decorative water features. They help retain water, prevent leakage, and maintain the aesthetic appeal of the pond or water feature.

- Q:What are the differences of seepage-proof membranes, geomembranes and waterproof membranes? Can they be used together?

- Seepage-proof membranes are mainly used in the waterproof control of civil engineering, are also widely used in municipal public sectors and highway engineerings, especially are commonly used in the slope protection; geomembranes are seepage-proof membranes with geotextiles as main materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Geomembrane HDPE for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords