Geomembrane Lagoon Covers

Geomembrane Lagoon Covers Related Searches

Blu Ray Player With Internet Geomembrane In Pakistan 30 Mil Pvc Geomembrane Pvc Geomembrane Specifications Pvc Geomembrane Geomembrane Machine Plastic Geomembrane Nonwoven Wallpaper Geomembrane Material Geomembrane FabricHot Searches

Geomembrane For Sale China Pvc Geomembrane China Geomembrane Roll Sheet Hdpe Geomembrane Sheet Price Hdpe Geomembrane China China Geomembrane Geomembrane China Hdpe Geomembrane Price Geomembrane Price Wholesale Hdpe Geomembrane Roll Geomembrane Factory Wholesale Liner Hdpe Geomembrane Wholesale Geomembrane Hdpe Wholesale Hdpe Geomembrane Geomembrane Market Size Wholesale Hdpe Geomembrana Wholesale Liner Geomembrane Geomembrane Liner Supplier Wholesale Geomembrane China Pvc GeomembraneGeomembrane Lagoon Covers Supplier & Manufacturer from China

Okorder.com is a professional Geomembrane Lagoon Covers supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geomembrane Lagoon Covers firm in China.Hot Products

FAQ

- nan

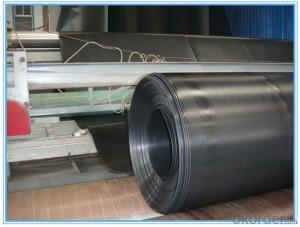

- Notes for geomembrane joints: (1) the joint treatment of the geomembrane is the key process of construction, which directly affects the service life of the project. Indicated by quality test, hot weiding is an ideal way. (special adhesive is also available). Heat welding method is heating the surface which is connected with the PE geomembrane, the surface melting, and then through the pressure to merge them into one, (2) Geomembrane shall be paved along a certain direction, on both sides of the geomembrane should be reserved for certain PE membrane and PET membrane bonding layer.While paving, we should adjust the tendency of geomembrane of each unit, in order to bring convenience to two units geomembrane welding. (3) Press geomembrane with sand bags to prevent wind after pavement, edge joints requires no dirt, moisture, dust, etc.. (4) before welding, adjust the joint at two sides of PE membrane, jointing them with broadband, and making them smooth, and no wrinkle. (5) When welding, it is better to have a technical personnel of certain experience, and use a special welding machine for welding. Adjust the temperature and speed, (can also use adhesive to bond). According to many years of practice, it is proved that the thickness of the geomembrane is not less than 0.25mm, because too thin is possible to produce porosity, and it is easy to be damaged in the construction to reduce the seepage control effect. During the construction of geomembrane, we should pay special attention that the pavement should not be too tight, shouldn't wrinkle, and the jointing should be firm. We should construct strictly according to the technical specifications, checking five quality clearance comprising preparation, paving, splicing joints, testing and backfill.

- Geomembranes contribute to geomembrane covers by providing a durable and impermeable barrier that helps to contain and protect various materials or substances, such as waste or liquids, from escaping or contaminating the surrounding environment. These synthetic membranes are designed to withstand harsh conditions and prevent seepage, ensuring the integrity and longevity of geomembrane covers in various applications, including landfills, ponds, reservoirs, and containment structures.

- nan

- composite geo-membrane takes plastic film as seepage-proof base material, it's the soil engineering seepage-proof base material composed by non-woven fabrics, and it's seepage-proof performance mainly depends on the seepage-proof performance of plastic film. it's dominant mechanism is isolating the earth dam leakage passage with the imperviousness of plastic film, it's good strength of extension and elongation can endure hydraulic?pressure and adapt deformation of dam; non-woven fabrics is also a kind of macromolecule staple fibre chemical material, it's made by needle punching or hot sticking, and has high strength of extension and extensibility, after combined with plastic film, it not only has increased the strength of extension and anti-puncture ability of plastic film, the rough surface of non-woven fabrics has increased the friction coefficient of contact surface, which is benefit to the stability of composite geo-membrane and packaging layer. meanwhile, they have good corrosion resistance to bacteria and chemical function, and can be resistant to the errosion of acid, alkali, salt.

- Yes, geomembranes are suitable for use in seawater applications. Geomembranes are designed to be impermeable to water and resistant to chemicals, making them an excellent choice for containment and protection in marine environments. They are used for various applications such as lining ponds, reservoirs, and coastal erosion control, where they effectively prevent the passage of seawater and protect the surrounding environment.

- Geomembranes are impermeable liners that are used in contaminated site remediation to prevent the spread and migration of contaminants. By acting as a barrier, geomembranes help contain and isolate the contaminants, minimizing their impact on surrounding soil, water, and air. Additionally, geomembranes can be used to create containment cells or caps, preventing further contamination and allowing for effective remediation activities such as excavation, treatment, or monitoring. Overall, geomembranes play a crucial role in the successful remediation of contaminated sites by providing an effective and reliable containment solution.

- Geomembranes contribute to erosion control in pipeline and utility corridor construction by providing a reliable barrier against soil erosion and water infiltration. These impermeable membranes are installed as liners or covers in areas prone to erosion, such as slopes and embankments, to prevent the loss of soil particles and the formation of gullies. By effectively containing soil and water, geomembranes help maintain the stability and integrity of the construction site, reducing the risk of damage to pipelines and utility corridors from erosion-related issues such as sedimentation or landslides.

- nan

- 1. In terms of reinforcement, the geogrid should be considered first. 2. The geosynthetics should not be laid directly on the surface of the original foundation. 3. When laying the geotextile material, it should be perpendicular to the axis of the road.

- nan

- Pavement and installation of geomembrane: 1, It should be extended from the bottom to the high, do not pull too tight, should be left with more than 1.50% of width in order to prepare for local subsidence. Considering the actual situation of the project, the construction of side slope is taken from top to bottom. 2) two adjacent longitudinal joints should not be in a horizontal line, and should be staggered over 1M. 3) longtudinal joints should be apart from dam toe, bending foot more than 1.50M, and should be located in the plane. 4) back slope first and then comes with bottom. 5) when paving side slope, the direction of the film should be parallel to the maximum gradient line. Secondly, we should do a good job in the preparatory work of the construction and installation of geomembrane welding: 1 cutting and transportation: According to the records of laying base measurement , cutting large bundle number of geomembrane should be marked and recorded and then carried to construction site according to their number. Attention: during the transportion, do not pull and drag geomembrane, and try to avoid sharp objects.