Composite Geomembrane with Nonwoven Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Composite Geomembrane with Nonwoven Geotextile

Introduction of Composite Geomembane with Nonwoven Geotextile:

It's made by non woven geotextile and PE/PVC geomembrane. Catagories are including geotextile and geomembrane, geomembrane wit non woven geotextile on both sides, non woven geotextile with geomembrane on both sides, multi-layer geotextile and geomembrane.

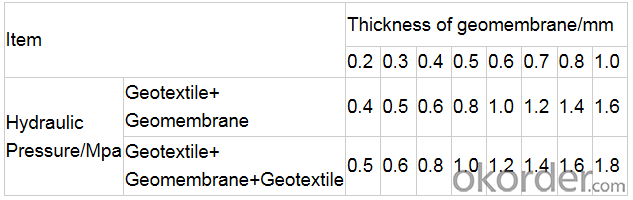

Specification:

1.One piece of geotextile and one piece of membrane;

Weight of base geotextile: 100-1000g/m2;

Thickness of geomembrane: 0.1-1.5mm.

2.Two piece of geotextiles and one piece of membrane;

Weight of base geotextile: 80-600g/m2

Thickness of geomembrane: 0.2-1.5mm.

3.One piece of geotextile and two pieces of membranes;

Weight of base geotextile: 100-1000g/m2;

Thickness of geomembrane: 0.1-0.8mm.

4. Multi-layers:Weight of base geotextile: 100-1000g/m2;

Thickness of geomembrane: 0.1-0.8mm.

Properties and Advantages:

Good flexibility, except of a geotextile’s isolation, drainage, reinforcement, protective functions.

It is also impermeable.

Usage and Applications:

Widely used in dam, traffic tunnel, road, airport, drainage, housing, environmental protection and many other fields for waterproof protection, reinforcement etc.

FAQ:

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

Photos:

- Q:Anti seepage coefficient of PE geomembrane

- PE geomembrane is water-proof, less than 1 American Standard basically means minus 13 power of 0*10.

- Q:Wallpaper to brush the membrane it

- The main function of membrane is to prevent moisture permeating from walls, not making the walls become moldy. It is better to brush the membrane, protecting the wall. Of course, if the quality of latex paint is good, it can not brush.

- Q:What is the power of electric heating film

- Taeil-500.338mm x 50cm x 110w\m x 150m (75 square meters \ box) Taeil-800.338mm x 80cm x 180w\m x 100m (80 square meters \ box) Taeil-1000.338mm 100cm x x 220w\m x 100m (100 square meters \ box)

- Q:The working principle of the water film dust collector?

- Its working principle is: Dust containing gas by simplified lower tangential rotation along the introduction, rise, dust particles by centrifugal force and is separated into the inner wall of the barrel body, the inner wall of the adsorbed water layer flow, with the water in the end part of the cone, the dust discharge port of unloading. The water film layer is formed by arranging a plurality of nozzles arranged on the upper part of the cylinder, and cutting the water along the tangential direction to the wall of the device. In this way, the inner wall of the cylinder is always covered with a layer of a thin water film which flows downward, so as to achieve the purpose of improving the dust removal effect.

- Q:What is the wall membrane?

- the damp-proof?basement membrane is a specialized alkali-resistant, anti-moisture, moldproof wall treatment materials, which can effectively prevent humidity and water and other alkaline material of the construction cardinal plane extravasation, and avoid wall decoration materials: Such as wallpaper, paint layer, plywood, decorative panels of damp, mildew and nigrescence and other undesirable damage. wallpaper basilemma is developed from water-based high-tech materials, harmless to the human body and environment without adverse volatile gases. compared with conventional oil-based alkyd varnish, it effectively protect the indoor environment, and the life of oil alkyd varnish is longer three to five times. Wherein the moisture-proof film is used elastic molecular materials, and it in the case of micro-cracks in the walls is effectively protect your walls.

- Q:What are the different methods of joining geomembranes?

- There are several methods of joining geomembranes, including thermal welding, adhesive bonding, and mechanical fastening. Thermal welding involves using heat to melt and fuse the geomembrane sheets together. Adhesive bonding involves applying a specialized adhesive to bond the geomembrane sheets together. Mechanical fastening involves using mechanical clamps or fasteners to secure the geomembrane sheets in place. Each method has its own advantages and suitability depending on the specific project requirements.

- Q:How do geomembranes prevent water seepage in storage tanks?

- Geomembranes prevent water seepage in storage tanks by acting as a barrier between the tank structure and the surrounding soil or water. The impermeable nature of geomembranes ensures that water cannot penetrate through the tank walls, preventing any leakage or seepage.

- Q:Which one is better, electric heating film and carbon crystal?

- The electric heating film and the carbon crystal electric heating board have their own advantages, and the carbon crystal is not necessarily better than the electric heating film.

- Q:Can geomembranes be used in aquaculture?

- Yes, geomembranes can be used in aquaculture. They are often used as liners for ponds, tanks, and other containment systems to prevent seepage and protect against water loss. Geomembranes help maintain water quality, provide a stable environment for aquatic organisms, and improve overall efficiency and sustainability in aquaculture operations.

- Q:How about the warm reflective film?

- It's good. Warm reflective film is a layer of aluminum foil which can reflect the infrared radiation produced by the heating film. Infrared radiation is a form of heat transfer. All the objects with temperature will produce infrared rays, even for the one of temperature of several degrees below zero. The fire is an example which transfers the energy through infrared radiation and does no harm.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Composite Geomembrane with Nonwoven Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords