Composite HDPE ASTM Standard Geomembrane / HDPE Geomembrane / ASTM Standard Geomembrane for Landfill

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomembrane waterproofing material

1) Good physical and mechanic performance

2) High tearing resistance, strong deformation adaptability

3) Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance

4) Good adaptability to high and low temperature, non-toxicity, long service life

5) Good waterproof, drainage, anti-seepage and damp proof effects

6) Complete width and thickness specifications, low cost and easy installation

Product introduction

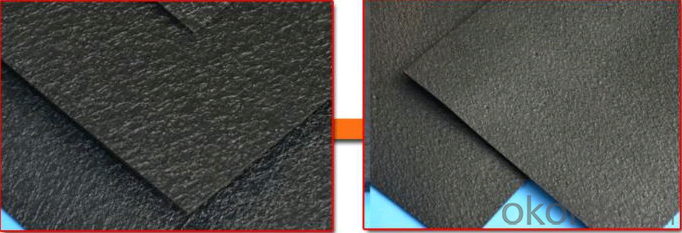

Geomembrane can be divided according to the different materials HDPE geomembrane , matte geomembrane , LDPE geomembrane , LLDPE geomembrane , EVA geomembrane , ECB geomembrane , PVC geomembrane.

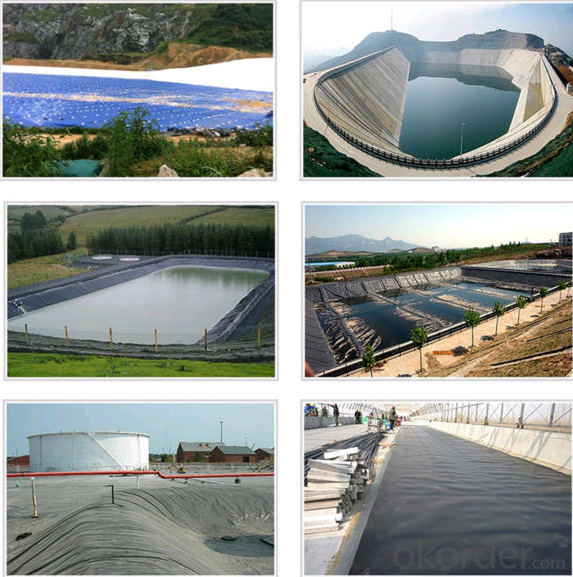

Product Use

1, City landfill ;

2, Roads, railways , drainage , irrigation , tunnels, dikes, dams , gates seepage, seepage accumulator library ;

3, Fluid channels , solid manure dumps impermeable ;

4, impermeable roof , building basements, underground storage , underground garage moisture ;

5, pile cofferdam film , land reclamation from the sea , marina projects etc.

FAQ

How about the delivery time?Lead time since receipt of 30% T/T deposit payment: 3 weeks.(Samples will be prepared within 3 days.)

2.What's are the MOQ?Generally speaking, the MOQ is one container, but we can provide you samples for quality inspection.

3. Do you charge for the samples?Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

4. Can you produce according to customers' design?Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q:What are the advantages of using geomembranes in desalination and water treatment plants?

- There are several advantages of using geomembranes in desalination and water treatment plants. Firstly, geomembranes act as a barrier that prevents the leakage of treated water, ensuring that the water is stored and transported safely. Secondly, these membranes are highly resistant to corrosion and chemical degradation, which helps to maintain the quality and longevity of the treatment infrastructure. Additionally, geomembranes are flexible and can be easily installed, reducing construction time and costs. Lastly, these membranes also provide protection against the contamination of soil and groundwater, thus preserving the environmental integrity of the surrounding areas.

- Q:Is electrothermal film floor heating safe?

- Safe

- Q:What is the cost of membrane structure?

- Membrane structure is a novel architectural form, compared with the traditional building materials, it has many advantages.

- Q:How to create a new fish pond water

- The geomembrane is a kind of polymer chemical flexible material, the proportion is small, the extensibility is strong, the deformation ability is high, the corrosion resistance, the low temperature resistance and the frost resistance are good. And geomembrane construction is simple, low cost, good anti-seepage effect. Fish pond laying geomembrane to leveling before compaction, not the root of gravel, to prevent the bad geomembrane. After finishing, measure the size, measure the bottom, slope, and leave enough margin. According to the measurement size to buy different specifications of the geomembrane, generally 6m or 8m wide, geomembrane laying, the film and the film between the lap 10cm or so, using a special welding machine welding, through the geomembrane to become a whole Good anti-seepage effect. After welding, the bottom can be backfill 20-30cm soil layer, the slope with non-woven fabrics to cover, to prevent the sun, to protect the purpose of geomembrane, increase the useful life. Geomembrane manufacturers to answer your questions

- Q:Is the hot air gun can be used to weld the composite geomembrane?

- The composite geotechnical membrane is generally welded by the as the special geotechnical membrane welding machine for welding hand - held hot air gun area of repair holes suitable for geotechnical membrane welding

- Q:home decoration glass insulation film is good or posted stickers decorative film.

- Effect decorative film may be a little better, it looks good; since the insulation film with insulation function, appearance and life may be not better than decorative film.

- Q:Are geomembranes resistant to UV degradation?

- Yes, geomembranes are generally resistant to UV degradation. They are designed to withstand prolonged exposure to sunlight and are often formulated with additives that provide UV stabilization, ensuring their longevity and performance in outdoor applications.

- Q:What are the requirements for geomembranes used in potable water applications?

- The requirements for geomembranes used in potable water applications include being made from materials that are certified safe for contact with drinking water, having a low permeability to prevent water leakage, being resistant to UV degradation to ensure long-term durability, and meeting specific standards for puncture resistance, tensile strength, and chemical resistance.

- Q:How are geomembranes tested for durability?

- Geomembranes are tested for durability through a combination of laboratory and field tests. These tests include measuring physical properties such as tensile strength, tear resistance, puncture resistance, and elongation. Additionally, accelerated aging tests are conducted to simulate the effects of long-term exposure to environmental factors like UV radiation, temperature variations, and chemical exposure. Field tests involve examining the performance of geomembranes in actual installations over an extended period of time to assess their durability and resistance to deterioration.

- Q:What are the differences between PE geomembrane and PVC geomembrane?

- PE geomembrane is of high density.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Composite HDPE ASTM Standard Geomembrane / HDPE Geomembrane / ASTM Standard Geomembrane for Landfill

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords