Aquaculture HDPE Geomembrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Aplication:

1) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

2) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

3) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

4), Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.)

And they are used in:

1.used in landfill caps

2. base liner applications under roads, railways,

3.secondary containment for above ground tank farms,

4.as well as within various other containment structures such as dams, canals, ponds, rivers and lakes

5.They are also used for waterproofing of buildings and other similar structures.

2.Product Characteristic

Our product was proved as good physical and mechanic performance, high tearing resistance, strong deformation adaptability, puncture,

aging, ultra-violet radiation, oil and salt, alkali and corrosion resistance, high and low temperature resistance, non-toxicity, long operational

life, good waterproof, drainage, anti-seepage and damp proof effects, complete width and thickness specifications, low cost and simple

construction.

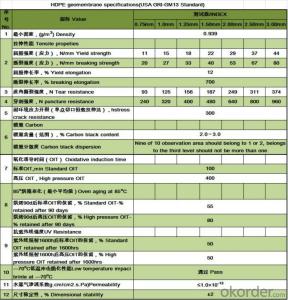

3.Product Specifications:

1.thickness : 0.1--3.0mm,

2.Length: 50 m -100 m ; width: 1 m -8 m ( according to customer needs )

3.Elongation at break:700%

3.Material: HDPE.

4.Color: Black or as your required

4.Reference Picture

- Q:Geomembrane classification

- Seen from the naked eye, particulate is because the feed back material is added too much. Secondly, take samples of the material on site and sent to relevant national authorities to be tested, while adding too much back material will cause the HDPE membrane not reaching American standard index, indicating that the material is not very good, but one thing you can see, as well as some granular things, sand holes on the membrane, which is difficult to distinguish

- Q:Can geomembranes be recycled?

- Yes, geomembranes can be recycled. They are typically made from various types of plastics, such as high-density polyethylene (HDPE), and these materials can be recycled and reused in various applications. Recycling geomembranes helps reduce waste and promotes sustainability in the construction and environmental industries.

- Q:What is the temperature of PET high temperature resistant film?

- high temperature resistant polyester film. It has excellent physical properties, chemical properties and dimensional stability, light transmittance and can be recycled. Cold resistance (--70 degrees), heat resistant ( 200 degrees), and has the good characteristics of corrosion resistance and shrinkage stability. High temperature resistance performance of protective films varies with the material of the film. PE electrostatic film is generally resistant to temperature of 60 degrees. PE high temperature resistant plastic is generally resistant to temperature of 120 degrees, and PET is 60 degrees -230 degrees theoretically, the actual situation remains to be customized and tested.

- Q:How do geomembranes perform in high temperature gas containment applications?

- Geomembranes are highly effective in high temperature gas containment applications. They are specifically designed to withstand extreme temperatures and maintain their structural integrity. These membranes have excellent thermal stability, allowing them to resist deformation or degradation even in harsh conditions. Additionally, they possess superior gas barrier properties, preventing any leakage or permeation of gases. Overall, geomembranes offer reliable and efficient performance in high temperature gas containment applications.

- Q:How to calculate the project quantity of raft foundation concrete?

- The raft foundation is also known as raft plate basis. the independent foundation under column or strip foundation are all connected with connection beams, and then cast baseplates. Generally speaking, raft foundation is used when the ground bearing capacity is uneven or the foundation is weak. And raft foundation is buried relatively shallow, which can be the foundation with no need of burying deeply. It is composed of baseplates, beams and other components. Buildings have a larger loading, and the foundation bearing capacity is weak, thus concrete baseplates are often used which can bear buildings loading, and form the raft foundation with good integrity, can be an excellent resistance to differential settlement of foundation. Project quantity should be calculated by cubic meters, the quota is the all-round foundation (05 quota)

- Q:Can geomembranes be used in agricultural waste containment?

- Yes, geomembranes can be used in agricultural waste containment. They are frequently used as liners or covers in agricultural waste management systems to prevent the leakage of waste into the surrounding environment. Geomembranes provide a barrier that helps in the safe storage and containment of agricultural waste, protecting the soil and water from contamination.

- Q:Geomembrane snz/ pvc-12-400-0.35 model

- (there is no manufacturer can produce 12m wide geomembrane at present) if it is SN/PVC-1, using 400g/ ㎡ polyester staple fiber geotextile and 0.35,another possibility is that your product model is wrong At the same time, according to national standard GB/T17642-2008. Combine 35mm thick PVC geomembrane together, using 400g/㎡ polyester staple fiber geotextile and 0. If this is geotechnical material used for seepage-proofing in the projects,

- Q:What is the geomembrane material?

- Geomembrane to plastic film as anti-seepage substrate, and non-woven composite made of soil impermeable material, new material geomembrane its impermeability depends mainly on the plastic film impermeability. (PVC) and polyethylene (PE), EVA (ethylene / vinyl acetate copolymer), tunnel applications are also designed using ECB (ethylene vinyl acetate modified asphalt), the use of plastic film, Mixed geomembrane), they are a kind of polymer chemical flexible material, the proportion of small, strong extension, adaptable deformation ability, corrosion resistance, low temperature resistance, good frost resistance. Mechanism: The main mechanism is to plastic film impermeable barrier earth dam leakage channel, with its large tensile strength and elongation to withstand water pressure and adapt to dam deformation; and non-woven fabric is also a short polymer Fiber chemical materials, through the needle or hot tack forming, with high tensile strength and extensibility, it is combined with plastic film, not only increased the tensile strength of plastic film and anti-puncture ability, and because of non-woven Surface roughness, increasing the friction coefficient of the contact surface, is conducive to composite geomembrane and protective layer stability. At the same time, they have good resistance to bacteria and chemical resistance, not afraid of acid, alkali, salt erosion, in the case of dark use, long service life.

- Q:Are geomembranes resistant to fire?

- Yes, geomembranes are generally resistant to fire. They are typically made from materials like high-density polyethylene (HDPE) or polyvinyl chloride (PVC) that have low flammability and are self-extinguishing. However, the level of fire resistance may vary depending on the specific type and thickness of the geomembrane.

- Q:How do geomembranes contribute to erosion control in airport runway and taxiway construction?

- Geomembranes contribute to erosion control in airport runway and taxiway construction by acting as a protective barrier against the erosive forces of water. They prevent water from infiltrating the soil, which reduces the potential for soil erosion and the formation of ruts, potholes, or sinkholes. Additionally, geomembranes help in maintaining the stability and integrity of the runway and taxiway surfaces, ensuring safe and smooth operations for aircrafts.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aquaculture HDPE Geomembrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords