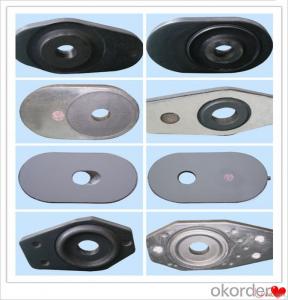

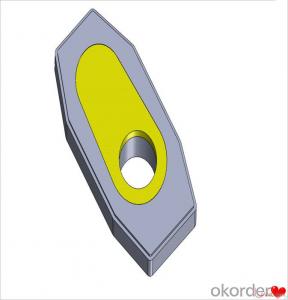

Flange Plate Connection

Flange Plate Connection Related Searches

Drill Bit For Aluminum Plate Router Bits For Aluminum Plate Aluminum Post With Base Plate 1/2 In Aluminum Plate 1/4 In Aluminum Plate 3 8 In Aluminum Plate 1/8 In Aluminum Plate Stainless Steel Strips Weight Of 1/2 Aluminum Plate Weight Of 1/4 Aluminum PlateHot Searches

Cheap High Tea Sets For Sale Mini Inverter With Battery Online Shopping Philips High Mast Lighting Price List Bajaj High Mast Lighting Price List High Mast Light Specification High Mast Lighting Suppliers South Africa Kitchen Table Sets On Sale Outside Bar Sets Sale Tinplate Factory Geomembrane Factory 1/4 Aluminum Plate Home Depot 1 8 Aluminum Plate Home Depot 1/2 Inch Aluminum Plate Near Me Induction Cooker Coil Price 1/4 Inch Aluminum Plate Near Me 1 4 Inch Aluminum Plate Near Me Aluminum Tread Plate Home Depot 1/2 Aluminum Plate Near Me 1 4 Aluminum Plate Near Me 1/4 Aluminum Plate Near MeFlange Plate Connection Supplier & Manufacturer from China

Okorder.com is a professional Flange Plate Connection supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Flange Plate Connection firm in China.Hot Products

FAQ

- What's the flange for?

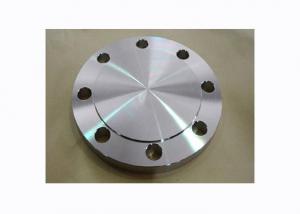

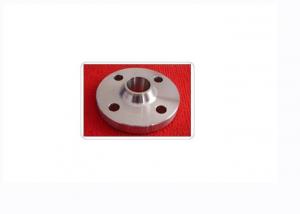

- Flange (Flange), also called flange or flange plate. The flange is the part that connects the pipe to the pipe and is connected to the end of the pipe. It is also used for the flange on the inlet and outlet of the equipment. It is used for the connection between the two devices, such as the reducer flange. Flange connection or flange connection, is defined by the flange, gasket and bolt connection between the three sealing structure of the detachable connection as a combination of group pipe flange refers to the pipeline installation of piping flange, used in equipment refers to equipment import and export flange. The flange is lined with bolts to secure the two flanges. Gaskets for gaskets between flanges. Sub threaded flange connection (threaded connection) flange and welding flange and flange clamp.

- PN40 valve flange surface using RF or FM?

- Our factory purchased PN40 valve flange faces are FM.

- Solidworks2012 use the default radius in the side flange. Can this default radius be fixed as a number I want?

- Draw a L type sheet metal, change the above bending radius, and later will automatically draw the drawing when the bend radius as the default bend radius. You can try it on this basis

- What do you mean by flange 2''3'' 4''?

- It should correspond to DN50, DN80, DN100 flanges

- CAXA2011 machine version, the big flange bolt hole evenly distributed, how to give the centerline?

- 1) implementation of array command immediately pop-up menu, the menu and operation instructions immediately according to the current requirements, can make a circular array, the array array graphics results for the uniform distribution, a number of 4.2) pick up the elements with the mouse, pick the graphics into bright red display, pick up, with the right mouse button to confirm. As an operation prompt, the result of an array copy is displayed when the center point and the base point of the array pattern are picked up with the left mouse button. The meaning of [central] and [reference] points can be seen by tagging.3) the system automatically rotates the graph in the array according to [2: rotation] in the immediate menu.4) the system automatically calculates the positions of each insertion point according to the [3: evenly distributed] and [4] numbers in the immediate menu, and the angles between the points are equal. The array patterns are evenly arranged on the same circumference. The share value should include the entity picked by the user.5) with the mouse click on the immediate menu [3: evenly distributed], the immediate menu is converted to the content shown in figure 4-47.The meaning of the immediate menu is that a circular array is arranged in a given angle, the angle between the adjacent figures is 30 degrees, and the filling angle of the array is 360 degrees. The array filling angle meaning to the entity from the pickup location, around the center of the inverse angle clockwise turn, adjacent angle and filling angle can be determined by the array of keyboard input.

- In the heat treatment, "flange" and "oxidation" there is a difference? Or is it just a different name?

- First you "flange" is wrong, should be "blue" it should be a kind of oxidation. It is the antirust treatment of metal surface. Should the general are included in the oxidation within barffing.

- What is the water line flange and what is the difference between it and the ordinary flange?

- Also called thread forty-five waterline waterline is thread like.In the HG20592-97 standard PN process: flange is less than 4.0MPa with non metallic flat gaskets; using PTFE gasket and flexible graphite composite gasket, car for forty-five waterline, sealing surface named RF (A)HG20592-2009 standard: convex surface, concave / convex surface and full plane sealing surface are processed by cutting tools, naturally formed a sawtooth shaped concentric circles or spiral teeth. The fillet radius of the cutting tool should be no less than 1.5mm, and the sawtooth concentric circle or spiral alveolus depth is about 0.05mm, and the pitch is about 0.45-0.55mm.The clearance and depth of outlet flanges are generally set by customers, usually 0.3mm-1mm wide.American Standard welding flange, sliding sleeve flange width 0.5-0.7mm general requirements. Flat flange customers are mostly required wide 0.7-1mm, depth 0.5-0.8mm.

- Excuse me can flange three, why the general flange is four hole

- The flange is according to size and standard, with American Standard, German standard, national standard, Japanese standard, British standard and so on. Generally, 1/2 "-24" requires 4 holes at the minimum. For example, in ANSI B16.5, 24 of the flanges are 20 holes, which play a joint and fixation role. But the non-standard flange can be made according to the actual situation and requirements, no matter the number of holes, specifications, or thickness, PCD and so on, can be done as required. Therefore, the non-standard flange can be made as required 3 holes