Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Sale!

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

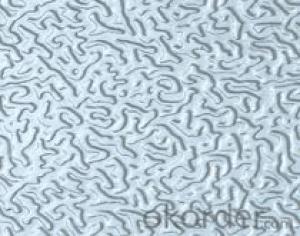

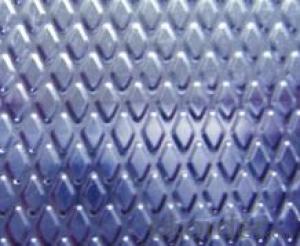

1.Structure of Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Sale:

Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Saleis widely used for decorative purposes in construction, packing and appliance. Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Saleis also very commonly used for anti-shippery purposes in vehicles and pulic places.

2.Main Features of Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Sale:

• Beautiful parten

• Good anti-slippery quanlity

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Sale

Alloy: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm-1500mm

4. Production of Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Sale

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q:Can aluminum sheets be used for protective barriers?

- Yes, aluminum sheets can be used for protective barriers. Aluminum is a lightweight and durable material that offers excellent strength and corrosion resistance. It is commonly used in various applications where protection is required, such as construction sites, industrial facilities, and military installations. Aluminum sheets can be easily fabricated and shaped to create sturdy barriers that provide a physical barrier to prevent unauthorized access or to safeguard against potential hazards. Additionally, aluminum is highly versatile and can be combined with other materials, such as glass or steel, to enhance its protective capabilities. Overall, aluminum sheets are a reliable choice for protective barriers due to their strength, durability, and versatility.

- Q:Can aluminum sheets be brushed or satin finished?

- Yes, aluminum sheets can be brushed or satin finished.

- Q:Can aluminum sheets be an alternative to glass in certain applications?

- Certain applications can consider aluminum sheets as an alternative to glass. Aluminum sheets provide various benefits over glass, making them suitable for specific scenarios. To begin with, aluminum sheets possess lightweight and durable characteristics, making them an excellent choice for industries like aerospace or automotive, where weight is a concern. Conversely, glass is relatively heavy and brittle, limiting its usage in certain environments. Moreover, aluminum sheets exhibit exceptional resistance to corrosion, making them a suitable option for marine or coastal applications, where glass may deteriorate over time due to exposure to saltwater. Aluminum sheets also possess a high strength-to-weight ratio, enabling greater design flexibility and structural integrity compared to glass. Furthermore, aluminum sheets offer superior thermal insulation properties in comparison to glass. They provide improved resistance to heat transfer, which is advantageous in applications where temperature control is crucial, like the construction industry. Additionally, aluminum sheets can be more cost-effective than glass in specific applications. The production and installation costs of aluminum sheets are often lower than glass, making them a more economical choice for large-scale projects. However, it is important to acknowledge that glass retains its own unique properties and advantages, such as transparency and optical clarity. Glass also has better resistance to scratches and chemical corrosion when compared to aluminum sheets. In conclusion, while aluminum sheets can serve as a viable alternative to glass in certain applications due to their lightweight, durability, corrosion resistance, thermal insulation properties, and cost-effectiveness, the final decision between the two materials depends on the specific requirements and limitations of the application at hand.

- Q:Are the aluminum sheets suitable for manufacturing automotive body panels?

- Yes, aluminum sheets are suitable for manufacturing automotive body panels. Aluminum is a lightweight yet strong material that offers several advantages for automotive applications. Its high strength-to-weight ratio allows for improved fuel efficiency and better overall performance of the vehicle. Aluminum also has excellent corrosion resistance, making it suitable for withstanding harsh environmental conditions. Additionally, it can be easily formed and manipulated, allowing for complex designs and shapes required for automotive body panels. These characteristics make aluminum sheets a popular choice in the automotive industry for manufacturing body panels.

- Q:Can the aluminum sheets be used for manufacturing aircraft engine components?

- Yes, aluminum sheets can be used for manufacturing aircraft engine components due to their lightweight, high strength, and good corrosion resistance properties.

- Q:How does the thickness of aluminum sheet affect its formability?

- The thickness of an aluminum sheet has a significant impact on its formability. Generally, thinner sheets of aluminum are more malleable and easier to shape compared to thicker sheets. This is because thinner sheets have lower resistance to deformation and require less force to bend or stretch. Thicker aluminum sheets, on the other hand, have higher resistance to deformation and are less malleable. They require more force and energy to shape, and may be more prone to cracking or tearing during forming processes. Thicker sheets also have a higher likelihood of experiencing springback, where the material partially returns to its original shape after being formed. The formability of aluminum sheets is also influenced by the alloy composition and the specific forming process being used. In some cases, certain alloy compositions or heat treatments can enhance the formability of thicker sheets, making them easier to shape. In summary, the thickness of an aluminum sheet directly affects its formability. Thinner sheets are generally more malleable and easier to shape, while thicker sheets require more force and are less malleable. The alloy composition and specific forming processes being used can also impact the formability of aluminum sheets.

- Q:What are the different methods for finishing the edges of aluminum sheets?

- Depending on the desired outcome and application, there are several approaches to finishing the edges of aluminum sheets. One commonly used method is edge trimming, where excess material is removed from the sheet's edges to achieve a smooth and straight edge. This can be accomplished using various tools like shears, saws, or routers. Another technique is edge deburring, which is employed to eliminate any sharp or rough edges left after cutting. Sanding or grinding tools are often utilized to smooth out the edges and produce a more polished finish. Moreover, edge rolling is a method that can be employed to create rolled or rounded edges on aluminum sheets. This is achieved by using a rolling machine that applies pressure to the edges, bending them into the desired shape. For a more decorative finish, edge profiling can be employed. This involves using specialized tools or machines to craft custom edge shapes or designs on the aluminum sheet. It allows for unique and aesthetically pleasing edges that enhance the overall appearance of the sheet. Lastly, edge painting or coating is an option worth considering. This process entails applying a protective or decorative paint or coating to the edges of the aluminum sheet. This not only provides a finished look but also helps protect the edges from corrosion or other damage. Ultimately, the choice of method for finishing the edges of aluminum sheets depends on factors such as the intended use, desired appearance, and specific project requirements.

- Q:Are the aluminum sheets suitable for manufacturing heat exchanger tubes?

- Yes, aluminum sheets are suitable for manufacturing heat exchanger tubes. Aluminum has excellent thermal conductivity, corrosion resistance, and is lightweight, making it an ideal material for heat transfer applications.

- Q:Can aluminum sheet be used for electrical enclosures?

- Indeed, electrical enclosures can indeed utilize aluminum sheet. The remarkable conductivity, lightweight composition, and resistance to corrosion render aluminum a favored option for electrical enclosures. It effectively safeguards against electromagnetic interference and possesses commendable heat dissipation properties. Moreover, aluminum boasts malleability, enabling the production of intricate shapes and designs. In summary, aluminum sheet is a fitting material for electrical enclosures and finds widespread application in diverse industries like electronics, telecommunications, and power distribution.

- Q:need help choosing an aluminum welder at a descent price also

- It all depends on what you are doing. For light duty stuff 1/8 to 1/4 inch a spool gun will be the cheapest option. For intricate work tig. For production a push pull unit with a pulse arc but these are big $.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum 5 Bars Plate/Tearplate of Good quality in Hot Sale!

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords