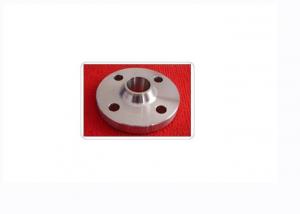

Flange EN1092

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 100 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

we can produce all kinds of EN1092 flanges

The main material for carbon steel, stainless steel and alloy steel, such as ASTM A105, A182, A350, A694, ST35.8, ST45.8, ST37.2, C22.8, SS400, SM400B, 20Mn, 20 #, Q235, 16Mn, F304/304L, F316/316L, F321, LF2,F11/42/46/52/60/65, 15CrMo, 12Cr1MoV such.

The production base total area is about 82,300 square meters.The annual production capacity is more than 9000 tons, with fine processing technology and advanced detection means.

The company has passed Rhine, Germany(TüV) ISO9001 quality management system certification , European pressure equipment and materials PED97/23/EC certification and German pressure equipment and materials AD2000-WO certification. It has also passed the pressure pipe components manufacturing safety registered certification of the State Quality Inspection Administration and classification societies certified .So a more effective guarantee is provided for the quality of the products.It has become the one of the enterprises firstly through the certification in the industry.It plays an important leading role in the industry.

- Q:What 150RJ and 150RF represent American Standard flange

- The RJ indicates the ring joint seal, and the RF is the face seal

- Q:What's the size of the 1 inch flange? What's the thread of the hole on the flange?

- It's an inch size, depending on what kind of flange you want, and one inch is 25.4 centimeters.The American Standard flange is expressed in inches. Domestic flanges are represented by DN for flange type and size, the DN25 A series is 34 in diameter (tubing), and the B series is 32 in diameter (tubing)

- Q:The choice of flanges for the European system and the American system

- Flange selection is mainly to see consistency, Europe or the United States there is no strict requirements, mainly taking into account the ease of use, unity.

- Q:SolidWorks assembly problem (the second holes on the flange can not fit coaxially)

- You see a screenshot of the I guess is the hole and flange you shell flange on the hole position is not the same (diameter distribution) please check the threaded hole hole diameter distribution Yuguang pay special attention to the thread size when the reference mark and position! ~

- Q:What's the outer diameter of the DN100 standard flange, please? Galvanized pipe with DN100

- The standard of the mechanical department is 215MM, and the chemical department is 220MM. They are all in common use

- Q:6 M12 are cloth, I can understand, but that attack 23 drill 24 what mean, according to reason, should be attack 23 drill 21, right?

- This should be M12 thread depth, drilling depth of 24mm, tapping depth of 23mm.

- Q:Why I can not find the SolidWorks2012 of the body flange buttons?

- The base flange is the first order of the sheet metal module. If the sheet metal module is not opened, it can be inserted under the sheet metal, and the first one is

- Q:When the toilet is fitted with flanges, is the rubber side of the flange facing the floor or the toilet? The installation is more reasonable.

- 1, the rubber ring side is toward the toilet, so that the toilet seat in the water outlet is easy to correct, it is best to ground glass glue, so that sealing is more difficult to leak.2, the flange ring is the sealing ring, also known as gasket. Currently more popular is the wax seal ring, also known as the wax sealing ring. Among the many industrial bearing to shock and wear resistant rubber pad called flange, basically need to use the toilet installation flange, but a lot of the toilet to reprovision. There is butter, polymer, the latter is more popular. The toilet (toilet flange seal) is put down the hole and the bathroom in the outfall, seals play a role, so that the siphon toilet flushing does not leak, the effect is very good.

- Q:What's the specification for flanges with outer diameter 160?

- The old labels JB81-59, 10kg-25kg, DN50, 2.5kg-6kg and DN65 are all outer diameter 160

- Q:Flange on the written A105, I do not know exactly what material

- Flange ASTM A105 forgings equivalent to 25 in ChinaThe corresponding pipeline with ASTM A105 GR.B corresponds to the domestic 20g, 16Mn

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong,China |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | qingda |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Flange EN1092

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 100 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords