WPC Decking Clips No Smell Fading and Bending Price WPC Flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1> What is WPC?

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

2> What’s WPC used for?

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

FAQ

3> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

4> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

5> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

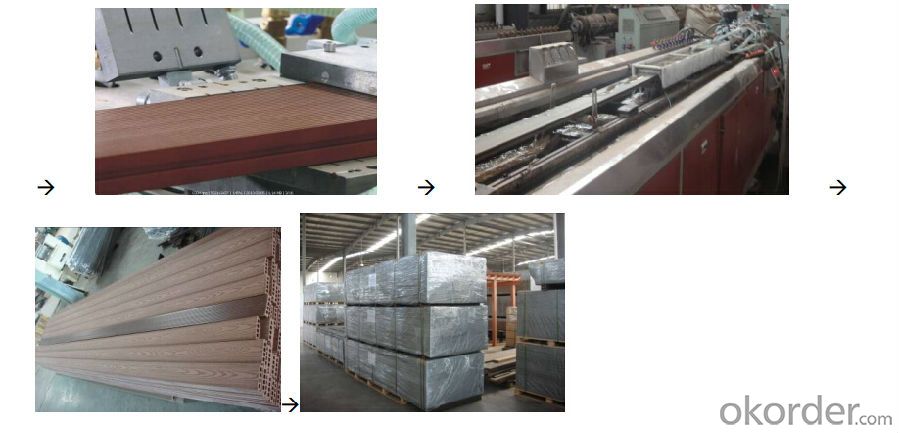

6> How’s WPC made?

7> Specification of WPC?

A. Weatherability

suitable from -40° C to +60° C, UV resistance

B. Test Data

| Testing Item | Technical Requirements | Value of Test |

| Water Content % | ≤2 | 0.4 |

Rockwell Hardness (HRR) | ≥60 | 80 |

Thickness Swelling after Water Absorption (%) | ≤1 | 0.2 |

Screw Holding | Surface of board ≥1300 | 3870 |

| End of board ≥1200 | 3460 | |

Static Bending | ≥20 | 28 |

Bending Elastic | ≥1800 | 4610 |

Abrasion | ≤0.08 | 0.06 |

Hammer falling impact in low temperature, broken (pcs) | ≤1 | 1 |

State after Heating | No babbles, cracks and pockmarks | - |

Rate of Size Change with Heating (%) | ±2.5 | -0.38~-0.45 |

Report Number: 201107126

Type of sample: 90x25x820mm, Solid

C. Surface treatment

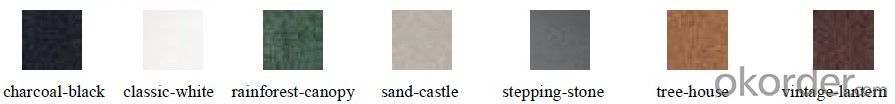

D. Main colors available:

charcoal-black; classic-white; rinforest-canopy;sand-castle; stepping-stone; tree-house; vintage-lantern .

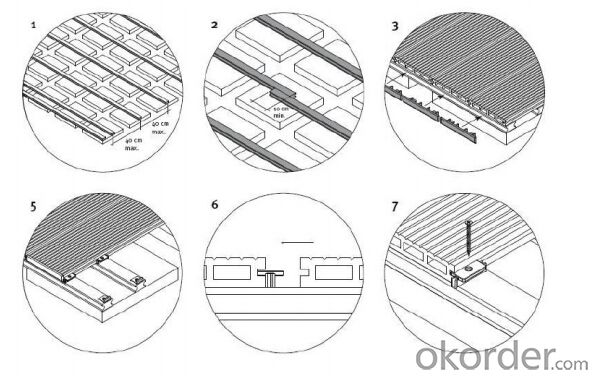

E. How to install

Company Information

8> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

Our unique advantages:

* Preferential payment terms

* Good and reasonable price

* Quality guarantee -- CNBM won't let a single small deal ruin our reputation and brand, so quality is

our lifetime.

* Professional team for CRM order processing & QA & logistics

*Global logistic database, originated from Dubai

- Q:I currently have a house where the bathroom floor is rotting in the corner right by the bath tub, how do we fix this and then is there something that we can lay underneat the new tile to prevent moisture from getting through?

- I'd go ahead..pull the tub...find where the water came from..put down a new sub floor..and floor..put a backer board up around tub...used to call this backer board green board..now they have one that's like sheet concrete(no, its not heavy....Lowe's has everything you need...not a bad repair for the do it your self-er

- Q:Considering using a large floor cloth to cover my wall-to-wall carpeting that I hate. I just want to drape it over the existing wall-to-wall. Where would you get floor cloth & exactly what is it made out of? I know you can paint it if you want to. Where would I buy this item. Can you get a piece of floor cloth 11 x 15 feet? Any information is appreciated.

- I don't know what your talking about. If you tried to use some type of cloth the cover your carpet, it would wear out fairly quickly. I would use an area rug in a pattern you found pleasing if you wanted to cover the carpet without changing the carpet.

- Q:I'm looking into buying my first horse trailer. What types of floors are there? I've heard of wood floors, aluminum floors, and rumber floors. Are there any others? And what are the pros and cons of these floors. Which one would you choose?

- The rubber mats are good for their feet, along with some bedding and barn lyme is really the best there is. The others could cause some problems. That way, you could buy any kind of trailer and fit the mat.

- Q:I have vinyl 12"by12" tiles that I am putting on concrete floor Henry 430 vinyl composition tile adhesive. The concrete floor is not perfectly even. In some places the gap could be as much as 1/8". I am trying to use the adhesive glue to fill this gap. Will this work? Can I use the glue to make my floor more even to put the tiles on. Thank you.

- You need to float the floor to make it flat. Do NOT use extra adhesive. It will never dry and will come up between the tiles for years. Use any good brand of float, Henry has one. Sand after it drys for a completely smooth floor. A pro installer will spend MORE time with the prep than the installing.

- Q:need help,i want a black and white room,i want black flooring,(modern)what can i use?

- My parents bought a black laminate flooring for their home. It it beautiful. I think they bought it at home depot. the only bad thing about black is that it is very hard to keep clean. everything shows up on it. I hope I helped and good luck

- Q:3dmax wooden floor how to use uvw map

- First use BOX to pull a floor block, and then the material lazy rough box Ngau Valley stubble in the long ball in the diffuse reflection with a bitmap to the wood floor of the map selected, attached to the BOX, and then in the floor of the editor to choose UVW map, adjust the parameters below the rectangle, set the length and width of the size of the line

- Q:We have Brazilian Cherry hardwood floors. Nothing I do seems to remove the streaking. I have wet mopped, steam mopped, used floor products with a dry mop, but always I can see streaks in the floors. Any suggestions on how to get them shiny and streak free?

- Spray thick amounts of bleach all over the floor. Then if you want you could put some car oil and mop it around too.

- Q:whats the easiest way to get it off the floor . been there since like 1984??????????

- I think your flooring, if from the 1980's, is probably linoleum. It can be tough to remove, as I just had to do this in my kitchen within the past year. ? Use a hammer and a wide chisel for small areas where it is really glued down tight. It's slow but works. Be sure to set the angled part of the chisel against the floor so that you don't end up driving the chisel into the wood sub-floor. ? In larger areas, a heat gun works great to loosen up the old glue and scrape up the remnants. They are pretty inexpensive and usually come with a chisel type attachment for removing linoleum. Good luck.

- Q:A)SubductionB)ConvectionC)RidgingD)Sea- Floor Spreading**Please and Thank you?

- D) Sea-Floor Spreading Choices A, B, and C do have to do with oceanic spreading, but are not the direct manner in which the new seafloor is formed. Sea-floor spreading is the volcanic activity at oceanic ridges that actually creates new seafloor.

- Q:Hi im trying to renovate my bathroom ,but im trying not to put that 1/4 inch cement floor to put the tile on cause its going to be biger than the living room floor is there anything else i can use that can be smaller than 1/4 inch floor board.i know theres like a thin membrain like paper or something ...please help

- You can use regular plywood as a sub-floor and it is cheaper.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

WPC Decking Clips No Smell Fading and Bending Price WPC Flooring

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products