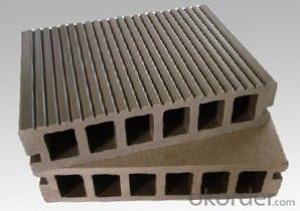

Wood Plastic Composite , Recyclable, Wpc Decking Floor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wood-Plastic Composite (WPC) floor accessory is manufactured from a combination of plastic, natural fiber and some additives using special equipments. It mixes natural fiber and plastic perfectly to keep the natural impression of wood but with rich colors of plastic. It has gradually replaced wood and plastic, getting widely used in more and more fields.

For our wpc decking floor, there are many kinds of types, such as TW-K01(150 x 35 mm)TS-01(150 x 25mm), TH-07(140 x 30 mm), TS-A01(90 x 20mm),TH-16(133 x 24 mm, solid design) etc..

1. Material: 50% natural wood flour; 35%~40%HDPE, 10%~15% additives

2. Color: cedar, grey ,red pine, coffee, brown, nature wood etc.

3. Usage: outdoor, garden, summer house, villa, pool surrounds, exterior floor, seaside walk board etc.

4. Normal length: 5.4 meters/pc, can also be cut according to the requirement of customer.

5. Surface treating methods: Brushing, groove, sanding, embossing etc.

6. CE Approved

7. Advantages:

Keep the excellent character of plastic | Have the properties of wood | Produce fire-new WPC |

weatherproof | easy to cut, fix and glue | Can be recycled with 100% |

no crack, split, warp, or splinter | easy to tenon , drill and nail | No sting of wood |

High dimensional stability | Natural feeling0 | Requires less routine maintenance |

Resistance to insects | Resistance to UV | Is environmentally friendly |

easy to manufacture manifold profiles | innocuous | Multicolor, and needn't to painting |

- Q:What is the floor of Warcraft?

- A is a shortcut key attack in the meaning of Warcraft A floor is A instead of A soldiers or heroes because you take the initiative A A hero will lead each other's soldiers to attack you and you approached the other side of the hero A floor hero will attack the nearest enemy That is, the other side of the computer automatically attack the enemy, then the opponent will not attack you

- Q:Last night around 11:30, my dad woke up and told my mom to clean the floors. He said it was a mater of life and death, and when she refused, he locked her outside her room. He then slammed my sisters door over and over again and threw random stuff. He then started mopping all the floors over and over again, and opened all the windows. I haven't seen him at all today. What the heck is going on?

- If he continues to act this way it could be something serious, if it's stress related it might stop. Either way it's not normal so have an intervention

- Q:Looking at it is not the original sleeping kennel `also deliberately bought a mattress pad pad` `but it must be drilled into the foam no tile on the` `` `` `` `` `` `` ` Tortoise Xiu Lu `` `` `` `` `` `` `` `` `` `` `` `` `` `` `` `` `` `` `

- Used to be natural, it is just as a place to sleep really need to master the patience to guide the tread will have a good habit

- Q:is it just laminate flooring?

- A sad excuse for wood flooring. Yes, they are an inexpensive means of achieving the hardwood look but, they will not wear the same way. You especially DO NOT want them in any area with the possibility of water exposure.

- Q:What brand floor did you go with? Are you satisfied with your floor?Most importantly for me is, how does your floor withstand spills, frequent mopping, & pet accidents?I want to install a floating vinyl-plank floor which has a natural wood look and feel, yet can withstand the abuse only a young puppy can provide.

- There only one type on the market, that I know off, that will with stand that kind of treatment. Thats Traffic Master Allure. The seams, when put together, are water proof. Most all click and loc floating floors will allow water between the seams. It will then seep down and be damp under your flooring. The only other thing is full sheet goods of vinyl. I ve installed this several times, along with in my GFs boys bedroom. We just went through a spring thaw and flood in the base ment were his bed room is. Didn t do a thing to the floor. Any questions you can e mail me through my avatar. GL

- Q:Would it be awkward to have tile on both the floor & counter top? We have white cabinets, stainless steel appliances & I want medium brown floors & counter tops...would this be weird?

- It's true that solid surface would be best; however, you can use a granite tile at a much lower cost than a slab. Use dark grout and seal it properly to avoid the problems the other person mentioned. As far as color is concerned; I think I might want the floor a little lighter than the counter tops - to make them pop. Same color family, just slightly different tones or textures. Also, if you don't have a lot of counters, you can ask for a discounted granite slab; most granite places have leftovers. Make sure you have some warm color lighting or accessories to spice up your look; like oranges or reds.

- Q:I installed a floating floor and it seems that water can penetrate between the seems. how could I seal these?

- Buff the floor with a floor buffer that has a white pad and a 220 grit sanding screen on the bottom. Then seal the floor with a sanding sealer, then follow that up with a coating of floor finish. I suggest Bona traffic floor finish.

- Q:A)SubductionB)ConvectionC)RidgingD)Sea- Floor Spreading**Please and Thank you?

- D- sea-floor spreadin caused by Mid-Oceanic ridges also known as divergent plate boundary where two plates are spreading apart and in the middle a rift valley is formed marked as the boundary between the spreadind. at the edges of the rift valley magma rises up to the surface and cools forming new sea floor.

- Q:Will water hurt Pargo flooring

- water wont necissarily ruin your pergo but if you spill something wipe it up immediately because its not good for the floor. Also if you thinking of installing in your kitchen maybe vinyl may work better. Check out the links I inserted and then make your decision i could be way off!

- Q:I am a dancer 8 years,I am redoing my and putting in floor that can be danced on but I an not sure what would be the best flooring. I want something simple since its my bedroom but I want a nice floor .

- Definitely a wooden panel flooring. Sprung if you can get it that way.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wood Plastic Composite , Recyclable, Wpc Decking Floor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products