White Polyurethane/PU Food Grade Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White Polyurethane/PU Food Grade Conveyor Belt

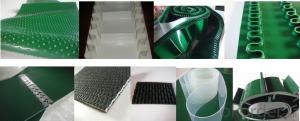

PU Conveyor Belt

Light duty conveyor belts are manufactured for all applications with various fabrics impregnation like polyester, nylon, cotton, solid woven, fiberglass etc. Belts are available in different colors like green, white, black, blue and thickness from 0.5 mm to 15 mm up to 3500 mm width and with top surface coating Rubber, PVC, PU, TPU, PE, TPEE, Teflon, Silicone, etc.

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Please contact us freely if you need any conveyor belt.

- Q:Can olive nets be used for olive trees in regions with limited sunlight?

- It is not recommended to use olive nets for olive trees in regions with limited sunlight. Olive trees require a minimum of 6 hours of direct sunlight daily to thrive and produce a good harvest. Using olive nets in shaded areas may further restrict sunlight and hinder the tree's growth and fruit production.

- Q:Are olive nets easy to store?

- Yes, olive nets are easy to store due to their lightweight and foldable design. They can be easily folded or rolled up and stored in a compact space when not in use.

- Q:How do olive nets prevent olives from being damaged by sunscald?

- Olive nets prevent olives from being damaged by sunscald by providing shade and protection from direct sunlight. The nets act as a barrier, limiting exposure to intense heat and ultraviolet rays, which can cause sunscald and detrimentally affect the quality and taste of the olives.

- Q:How do olive nets help in reducing the risk of nutrient deficiencies?

- Olive nets help in reducing the risk of nutrient deficiencies by providing protection to the olive trees from external factors such as pests, birds, or extreme weather conditions. By preventing damage to the olive trees, the nets ensure the trees can continue to grow and produce olives, which are a valuable source of nutrients. This helps to maintain a consistent supply of olives and subsequently reduces the risk of nutrient deficiencies for individuals who rely on olives as a part of their diet.

- Q:Can olive nets be used on olive trees grown in containers?

- Yes, olive nets can be used on olive trees grown in containers. Olive nets are primarily used to protect the olives from birds and other pests. Whether the olive tree is grown in a container or in the ground, the nets can be placed over the tree to provide the same level of protection.

- Q:Do olive nets affect the tree's growth or health?

- Yes, olive nets can affect the tree's growth or health if they are not properly installed or maintained. If the net is too heavy or tightly wrapped around the tree, it can restrict the tree's ability to receive sunlight, air circulation, and nutrients, leading to stunted growth or weakened health. Additionally, if the net is not regularly checked and cleaned, it can trap moisture, pests, or diseases, further impacting the tree's overall well-being. Therefore, it is important to use olive nets carefully and ensure they do not negatively impact the tree's growth or health.

- Q:Are olive nets suitable for olive tree nurseries?

- Yes, olive nets are suitable for olive tree nurseries. These nets provide protection from pests, birds, and excessive sunlight, creating a favorable environment for the healthy growth of olive trees in nurseries.

- Q:Can olive nets be used in combination with pruning activities?

- Yes, olive nets can be used in combination with pruning activities. Olive nets are often used to collect the pruned branches and leaves, preventing them from falling to the ground and potentially causing damage or creating a mess. By using olive nets, the pruned material can be easily collected and disposed of, saving time and effort in the cleanup process. Additionally, the nets can also act as a protective barrier, preventing the pruned branches from falling on workers or damaging nearby plants.

- Q:Do olive nets damage the olive tree?

- No, olive nets do not damage the olive tree.

- Q:How do olive nets prevent olives from being damaged by windstorms?

- Olive nets prevent olives from being damaged by windstorms by acting as a protective barrier, effectively shielding the trees and their fruits from the strong winds. The nets are securely tied around the trees, creating a physical barrier that prevents the olives from being blown off or damaged by the force of the wind.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

White Polyurethane/PU Food Grade Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords