White Food PU Conveyor Belt Thickness 1.5mm/3.0mm Smooth

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White Food PU Conveyor Belt Thickness 1.5mm/3.0mm Smooth

PU Conveyor belt fabric layers:

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

Appearance:

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Application:

PU: Most applicable to the food industry and other industries .

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

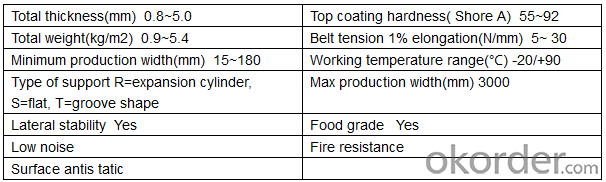

PU Conveyor Belt Specification

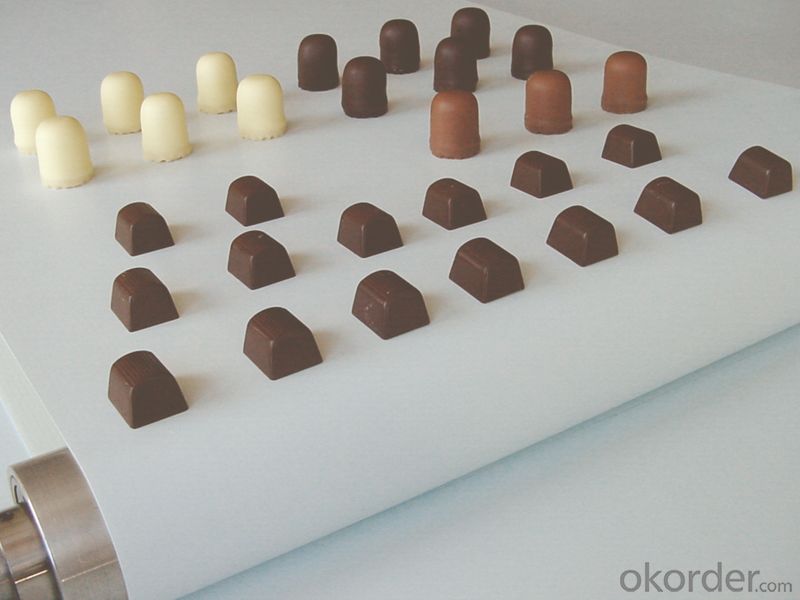

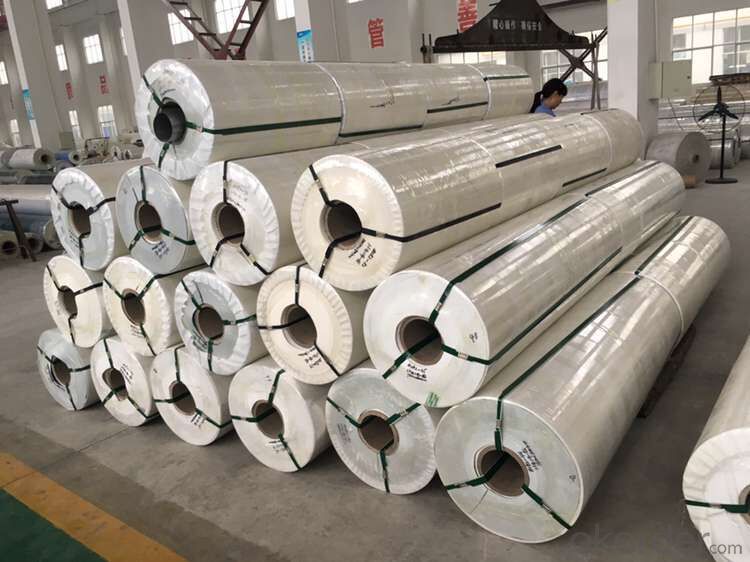

Photos of Food PVC Conveyor Belt

FAQ

Can you give me discount?

Yes, of course. If you talk with us, you’ll get more.

Will you send me free sample?

Yeah, she'd love to; can you buy her a ticket?

Do you like to accept small orders?

We enjoy to grow up together with all our clients, whatever big or small.You will become bigger and bigger to be with us.

Buyer attention

If you are interested in our products and company, please leave a message here or E-mail to us, We will reply you without any delay.

- Q:Can olive nets be used for table olive production?

- Yes, olive nets can be used for table olive production. Olive nets are commonly employed in olive farms to collect table olives during the harvesting process. They are spread under the olive trees to catch the falling fruit, ensuring minimal damage and facilitating efficient collection. Olive nets help maintain the quality of table olives by preventing them from coming into contact with the ground and reducing the risk of contamination.

- Q:Are olive nets suitable for organic farming practices?

- Yes, olive nets are suitable for organic farming practices. They are commonly used in organic olive farming to protect the crop from pests and birds without the need for synthetic pesticides or harmful chemicals. Olive nets provide a natural and eco-friendly solution for organic farmers to maintain the quality and yield of their olive harvest.

- Q:How to classify waste plastics? Identification methods?

- In general, transparent plastic bags, such as common use fresh-keeping bag, belonging to recycled plastic bags, and opaque plastic bags, such as markets with color and black plastic bags, garbage bags, transparency, flexibility is poor, belongs to Unrecyclable plastic bags. The reason is that opaque plastic bags are made from waste plastics and have lost the value of recycling.

- Q:Does high strength polyurethane belong to plastics?

- Rubber and plastic are juxtaposed terms, no one belongs to anyone.

- Q:Can olive nets be used in combination with other types of insect control methods?

- Yes, olive nets can be used in combination with other types of insect control methods. Olive nets are primarily used to protect olive trees from insects, but they can be complemented with additional measures such as insecticides, pheromone traps, or biological controls to enhance the effectiveness of pest management.

- Q:Are there any alternatives to olive nets for harvesting olives?

- Yes, there are alternative methods to olive nets for harvesting olives. Some alternative methods include hand-picking olives, using mechanical shakers to remove olives from the trees, or employing vacuum suction devices to collect fallen olives. Each method has its own advantages and disadvantages, and the choice of alternative harvesting method depends on factors such as tree size, terrain, and desired yield.

- Q:What is the plastic bottle used to make after crushing?

- In appearance, we can not see the difference between raw materials and feed back, but because the feed back contains impurities, it will affect the aging properties of plastic, and the quality of the product will be worse!

- Q:Are olive nets suitable for both traditional and modern olive farming practices?

- Yes, olive nets are suitable for both traditional and modern olive farming practices. Olive nets are used to collect falling olives during the harvest season, whether they are manually shaken from the trees or mechanically harvested. This method is common in both traditional and modern olive farming practices, making olive nets a versatile and effective tool for olive farmers.

- Q:How does the cost of using olive nets compare to other harvesting methods?

- The cost of using olive nets tends to be lower compared to other harvesting methods.

- Q:Can olive nets be used in combination with shade nets?

- Yes, olive nets can be used in combination with shade nets. Olive nets are primarily used to protect the olives from birds and other pests, while shade nets are used to provide shade and regulate temperature in agricultural settings. By using both nets together, olive trees can be protected from pests while still benefiting from the shade provided by the shade net.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

White Food PU Conveyor Belt Thickness 1.5mm/3.0mm Smooth

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords