Waterproof Calcium Silicate Board Tiles Calcium Silicate Board Tiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

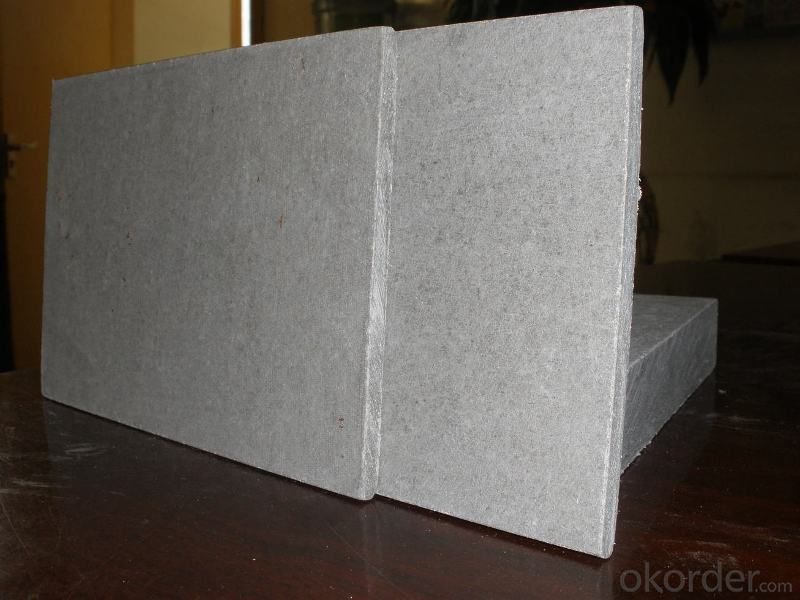

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

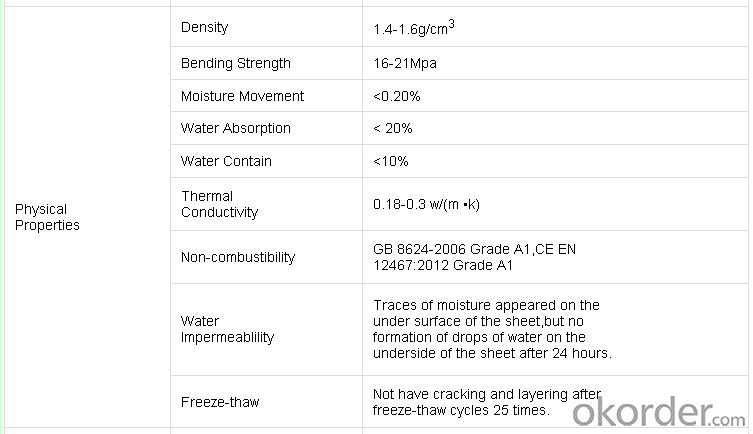

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q:I have 3/4 hardwood in the living and dining rooms and was wanting to avoid any step transitions. Any suggestions or opinions would be appreciated.

- First decide what kind of tile you want to use for your entry. then measure it. Measure the difference in height between your hardwood and sub floor in your entry. Subtract the tile thickness + 1/8 for mortar (if using mortar). That will give you the necessary thickness of your cement board. You will probably have to use a threshold or transition strip of some sort to cover the seam even if you get the floors the exact same height, so I wouldn't stress too much.

- Q:What is the process of using a cement pressure plate to dry the tile? What do I need to know about the specifications of the light steel keel, how thick the board

- This process is the traditional practice, said in front of the keel of course, is 50 and 75 of the main, depending on the wall area, keel spacing is the same, a large area of 400-600MM can accept, if the package, duct Of course, depending on the size of the pipeline.

- Q:I've taken up old linoleum tile, chip board, and two other layers of linoleum to get down to an oak floor in my bathroom. This has a felt-like paper uniformly adhered to it that must have been the backing for the first linoleum layer. I'm going to put down Hardi-backer, then tile. Do I have to take up the old tile backing material before I put down the hardibacker? It's very difficult to remove. Thanks!

- it is ok to go over that thin layer of paper

- Q:The scope of application of foam cement

- Pipeline backfill. Underground abandoned oil tanks, pipelines (built-in crude oil, chemicals), sewage pipes and other holes easily lead to fire or landslides, the use of foam concrete backfill can solve these troubles, the cost is also less. The density of foam concrete depends on the diameter of the pipe and the groundwater level, usually 600-1100kg / m? ;.

- Q:How to apply waterproof material on the cement board?

- You can first brush again JS composite flexible waterproof coating, and then brush it again K11 waterproof coating paint; or brush twice straight JS composite elastic waterproof coating, so you can have a good crack resistance.

- Q:Does backerboard need to be installed for new kitchen tile with cement floor?

- No, you can tile directly onto the cement floor. Check to make sure it is level and also repair any holes or cracks before you start. If your floor is not level, the easiest fix is to buy self-leveler at any home improvement store. It is runny, kind of like water, and it finds its own level and then sets -- and you can then tile on top of it.

- Q:I can jump atleast 4 or 5 inches on a rug,grass, mud, sand. but i cant on cement when i ollie on cement my board like slips away after i pop and on everything else it doesnt. help?

- It is cause you have got so used to doing it on carpet. I wouldn't recommend anyone learning tricks stationary on carpet. Just keep practicing it. You will have to relearn it on cement.

- Q:There is a problem like your team to ask the partition wall have what form in addition to light steel keel gypsum board there are no other

- Factory or office, then you can use Caigang sandwich panels, the family can use colored glass sliding door or do closet to do partition

- Q:i am having alotta trouble on the cement like i cant get both feet back on the board.any tips?

- try it on a smoother platform....wood? maybe. try using sneakers or some sort of a shoe that has a rubbery feel on the bottom. because, the concrete here is very scratchy and has many bumps. it gets annoying i cant even stand on a skateboard without hurting 1 part of my body here. haha. tried it. lol

- Q:Can cement board be tiled?

- Kitchen flue is made of cement board if the wall is not hard to use the red brick and then posted again

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Waterproof Calcium Silicate Board Tiles Calcium Silicate Board Tiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords