Tubular Fabric Edge-Cutting Winding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery of Tubular Fabric Edge-Cutting Winding Machine

Packaging Details: Wooden case/ pallet or as your request.

Delivery Detail: 7-15 Days after confirm the order.

Specifications of Tubular Fabric Edge-Cutting Winding Machine

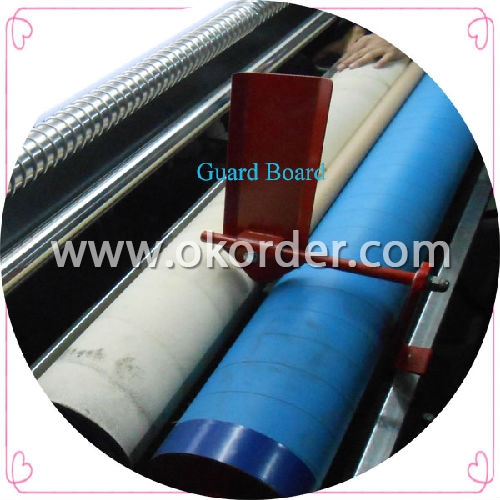

Edge-Cutting Winding Machine

1.Hydraulic edge-aligning system

2.12 years expreience

3.Used tubular knitted fabric

4.CE

Usage of Tubular Fabric Edge-Cutting Winding Machine

Tubular Fabric Edge-Cutting Winding Machine is specially designed to slit, inspect and rewind tubular fabrics and it is suitable for knitting plant.

- Q:What is finishing finishing after finishing?

- Generally in a state of tension with the subsequent process of slightly higher temperature processing, that is, heat setting to prevent shrinkage of the fabric deformation, in order to facilitate the post-processing.In addition, the use of heat-setting process combined with other physical or mechanical effects also Can be made elastic yarn (silk), low elastic yarn (silk) and yarn expansion yarn.

- Q:What is the digital printing machine?

- The advantages of such printing methods: the printing process does not require water resources, will not cause pollution to the environment. The advantages of such printing methods: the printing process does not require water resources, will not cause pollution to the environment.

- Q:What is the fabric characteristics of clothing?

- As one of the three elements of clothing, fabric can not only interpret the style and characteristics of clothing

- Q:What is the difference between embossing and etching?

- Hot out of the site will be shiny, and no hot parts of the formation of contrast and produce flowers

- Q:What are the advantages of soy protein fiber products?

- . the appearance of luxury. Clothing fabrics in the appearance of the people's feelings reflected in the gloss, drape and weaving delicate degree of three aspects. Soybean protein fiber fabric with a silk-like luster; its drape is also excellent, giving the feeling of elegant and refined; with high-woven yarn woven fabric, the surface lines fine, clear, is the high-end shirt fabric.

- Q:What are the classification of dyeing and finishing auxiliaries?

- 2, the retention of additives is treated, the agent mechanically precipitated on the fiber or with the chemical reaction and combined in the subsequent process is no longer removed, resulting in more lasting many effects, many finishing agents and flame retardants, Softener and so are a retention agent.

- Q:What is the turntable printing machine?

- The But because of its limited labor, India need to print one color drying one color mortar and in the dark cloth on the need to hit the white heat of the ink

- Q:What are the technical routes for liquid ammonia finishing?

- 58tex, 5.83tex Abbott liquid by liquid ammonia after finishing, flexibility and dimensional stability of a greater increase, the appearance of flat Ting, soft to the touch, a strong sense of silk, and if the combination of resin finishing, the product can reach the PP level.

- Q:Textile cad and mechanical cad the same?

- Mechanical is convenient mechanical, a variety of standard parts, signs, symbols, can be directly inserted.

- Q:What are the classification of knitted fabrics?

- Yarns are warp knitted in warp knitted fabrics, like warp yarns of warp knits, which are spun by a warp beam and have a large number of parallel aligned yarns on the warp and similar to the warp in the weave. The direction of the yarn in the warp knitted fabric is warp

1. Manufacturer Overview |

|

|---|---|

| Location | Changshu, China |

| Year Established | 2008 |

| Annual Output Value | 15Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 20 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 8000 square meters |

| No. of Production Lines | Above2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Tubular Fabric Edge-Cutting Winding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products