Swing Check Valve Wafer Type Double PN 2.5 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

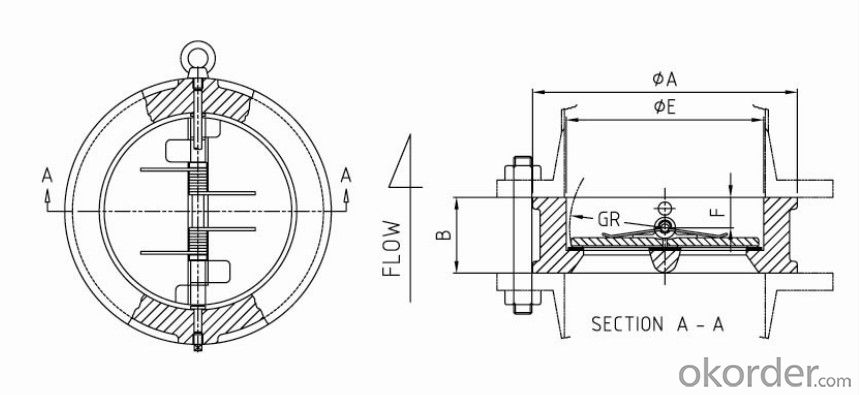

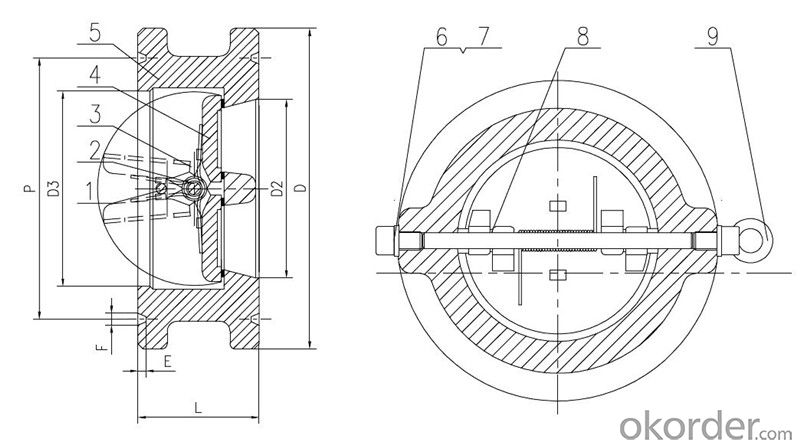

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

- Q:i have been having these chest pains and i went to the doc. they did an ekg, blood test for enzymes and a echo. Well today i went back for the results of the echo and was told that i had a leaky valve but it was nothing to worry about and that there are just trace amounts of valve regurgitation. Im only 19 and i have no other history of heart problems or diseases should i be worried...they said i didn't need any anti biotics or anything and that it wouldn't kill me just to watch for it as i age into my latter years of life 50-70, but im still kinda worried..anyone else have this? im also pregnant and im concerned as to how this will affect my pregnancy, labor and delivery????

- i had a heart valve plomble when i was a baby i know I'm mother and a wife after i had my son they fix my valve and i doing real good know have a other doctor check it out

- Q:will adding a bypass valve onto an air filter effect gas milage or horsepower?

- bypass valves are for cars with forced induction IEturbocharger,supercharger it allows the air that would normally be expelled into the atmosphere blow off valve and instead putting it back into the intake which helps with less lag in building boost again. If your car is not turboed or supercharged then forget it.

- Q:I am modelling the production of phthalic annhydride and my process has a lot of FIC, LIC, PIC notations in circles on the connections. Moreover there are what i think are temprature and pressure notations in a square and a triangle. But most primarily what does a pneumatic valve do?

- pneumatic valves use pressurized gas (Air, nitrogen) to operate.A simple example if you are monitoring the level of a vessel in a process the indicator for level (LI) tells you remotely what the level is. If you need to keep the level stable the level indicating controller (LIC) sends a signal to the regulator on the Pneumatic Valve which provides air to open or close the valve depending on what the vessel level set point is. the FIC (flow indicating controller) PIC (pressure) TIC (tempurature) are all instrumentation used to compare a set point parameter against a measured process variable and send a signal to control the valve to maintain the set point

- Q:so, im a day away from getting a 2002 748 and im super excited, iv always wanted a ducati, and i cant wait to have one of my own. i understand that ducks have a reputation of breaking and im prepared for it. I also understand the valves need to be adjusted every 50-100 feet :P all kidding aside i know every 6k miles they need to be adjusted. i dont know however how much it costs to have the valves adjusted. im sure it varys from shop to shop but a ball park quote would be really helpful just so its not a kick in the gut when i take it in for the first time. thanks

- believe it or not a desmodromic valve adjustment takes like 8 hours.So its kinda costly to do that job.

- Q:Ok. i just got my trumpet and i barely know anything about it. my trumpet book says, oil your valves but i cant even get them unscrewed, its like theyre glued in there...or maybe im just doing something wrong. Helppp

- Well on the valves you will see there are caps on the bottom and top of the valve. The top cap (it is located at the top of the valve itself, not the button you press - it is the cap that the button lands on when pressed) you unscrew that and take the valve out to oil it. Just make sure you put it in back correctly, if you put it in incorrectly it will not play properly. Also don't drop or dent the valves as they are very delicate and the smallest dent can damage it. Make sure that when you unscrew it that you only use your fingers. DO NOT use any tools to get it unstuck otherwise you can damage the instrument. It would be best for you (because you're new at the trumpet) to take it to the local music store and ask them how to take care of a trumpet. I am sure they will be happy to show you. Hope that helps

- Q:We have an ejector in the basement for an in-law apartment. When the check valve kicks in, it can wake us up from a sound sleep. A very loud thunking. Any ideas?

- the check valve would be installed just outside of the crock vertically. The noise I doubt is from the check valve itself. I'd guess it is the pump shutting off and the pipe isn't fastened securely, so it bangs. Check to make sure that the run of pipe leaving the crock is fastened securely. if this is the case the only other option I oculd think of would be to re-position the check valve on a horizontal run of pipe as close to the crock as possible. Most check valves I have seen for ejectors are compression type, it will be messy but not to complicated. Keep a bucket handy, when you crack open that check valve you may need it. Flush the toilet until the pump kicks on a few times, this should clear out most of the nasty stuff. You may also need a short piece of 2 pipe and some couplings to make up for the space of the check valve. If you can hear the water flowing out when the pump kicks on and don't hear it draining back into the crock when it shuts off, the check valve is probably still good.

- Q:I have to get a new vacuum switching valve for my 1987 toyota pickup. I was just wondering what it does, and if a broken one would cause my truck to not idle. It still runs fine when i drive it, but when i push the clutch in the RPM's get really low until it dies.

- This valve probably is the EGR control valve - the computer monitors the EGR flow and controls the EGR valve opening by switching vacuum to it for opening or bleeding vacuum off for closing. If this valve fails to completely close the EGR valve at idle, the problem will mirror your symptoms

- Q:I heard there are really fine valves, does someone possesses thoughts where to buy these goods? I heard about them on TV. Anybody alive?

- Yes, okorder

- Q:whats the location of the pcv valve on on a 2001 bmw 740il (e38)

- In front of the engine slightly to the left and lower area of the throttle valve. It is a round black plastic canister supported by a teardrop shaped rubber with a cable connector at the top and 2 hose connections at the opposite end of the cable connector which are perpendicular to each other. BMW calls it the tank vent valve.

- Q:I am replacing the Camshaft, lifters, and timing chain on a SBC 350. The motor is still in the car and I have the valve covers and manifold removed (and other components). The camshaft break-in procedure recommends removing the inner valve springs and running engine at 2000-2500 rpm for 20-30 minutes. MY QUESTION: I have the valve spring compressor tool to remove the springs. HOW do I prevent the valve from falling into the cylinder when I remove the spring? Can I conduct the break in without removing the inner valve springs?

- Depending on the position of the plug holes relative to the valves you just might be able to fashion a piece of realy stiff, strong wire into a support for the valves whilst you remove the springs, but this would also depend on the spring compressor not needing to use the head on the valve to do the compressing. It is highly likely that with everything in your favour the above method will fail and you will be obliged to remove the head. I would simply remove the to take out the springs and then remove it again to replace them after running in.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Swing Check Valve Wafer Type Double PN 2.5 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords