Swing Check Valve Wafer Type Double Disc Body Material WCB

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

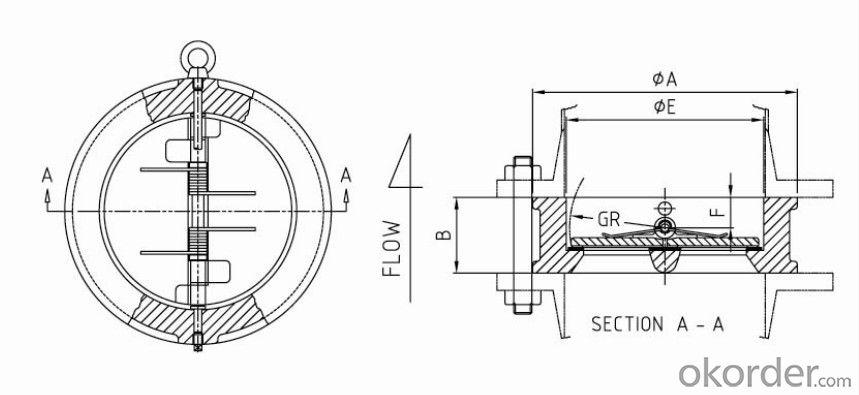

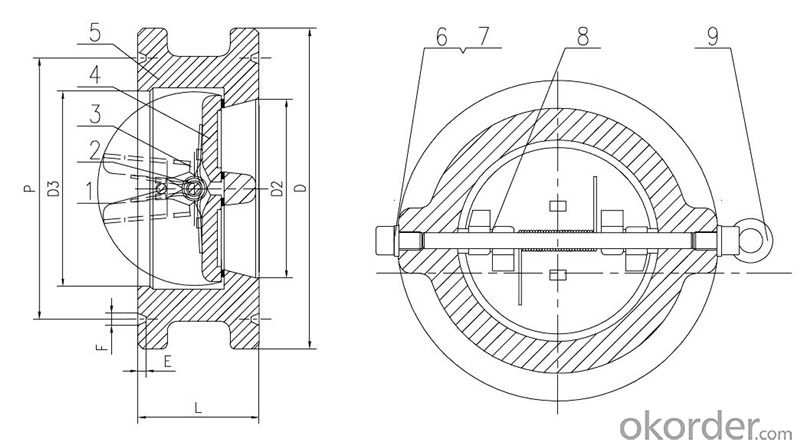

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q:is it possible to check valve to piston clearance with out taking the heads off? I want to buy a bigger camshaft for my 351 windsor stock pistons with 1970 heads. cam is 230 duration (280) and 512 lift

- The piston isn't the issue here, the issue would be the valve springs. Stock Ford small block springs will bind at .500 lift, this cam will require new springs. If you don't have adjustable rocker arms (most Fords are a postive stop or torque value) you will need an adjustable valve train also. 351s and 289s BOTH use 4 inch pistons, and you CAN'T put a 3.5 inch (351) crank in a 289!

- Q:My sump pump shut-off valve is very noisey. I wrapped insulation around it, but it still clunks. The clunk can keep me awake.

- If you mean the discharge check valve, it will clunk when the level switch trips the pump. The head or weight of the water trying to flow back into the crock causes the check valve to slam closed, making a clunking sound. This is pretty common and normal.

- Q:12 valve

- Un plug the vacuum hose on top of the valve, loosen and remove the big tube nut on the bottom of the valve, I have found if you hit it sharply with a hammer 3 or 4 times before you try to loosen it won't break the valve off, once the tube nut is undone remove the 2 bolts holding the EGR valve to the intake manifold. Remove and discard the gasket and install the new valve in the reverse order. If the tube nut still won't come loose try heating it with a torch, if it's really rusted on you might have to replace the EGR tub along with the valve.

- Q:I threw a birthday party last night, all went well until 2am when a crazy (drunk!) lady cut all the wires from my heating system (i guess as a prank??? dunno, she is never invited back). I have everything up and running when using one thermostat and connecting the thermostat wires (red directly to tv, Brown directly to W, and white directly to T) and not using the two Honeywell zone valves (model number V8043F. How do I connect those two zone valves to the L8148E aquastat?The valves have on bottom Th-TR, TH and TR and the two top screws are labeled end switch.If you need photos I can take them :)Thanks in advance!

- Honeywell Aquastat L8148e

- Q:i have an old 79 malibu and its only got a 267 in it. I wouldnt buy new valve covers because its not worth it to me but i was thinking i could clean the ones i got up a little bit. i was thinking of painting them. What kind of paint should i use? and one other thing is the gaskets. I figure while i have them pulled off i should put new gaskets on. I read up about getting all the old stuff off but i was curious still about it. I was just looking at some average ones made of cork for 10 bucks. Do i lay the sealer downthen put the gasket on , then put the valve cover on?

- the best thing i could tell you is clean them good and when you put the gasket on dosent matter if its cork or not, but the silicon ones are better, is that to make sure that the mounting surface's are clean. and have no oil on them otherwise your gonna have a leak. as for the pain clean em good and it really dont matter which paint

- Q:I just want to ask do i turn clockwise or counterclockwise in the pipe main shutoff valve to turn on the water supply?

- left to open an right to close piece of cake. (grate now i want some cake)

- Q:I have a Jupiter double horn. The thumb valve will randomly stick down and not want to come back up. It however only does this when I play a scale or am in the middle of a song, so when I ask the director or an instrument repair person to help, they think I'm crazy and see nothing wrong with it. Also, the first valve is slightly bent sideways towards the second valve. I got it used and it came like this. It is not horrible, but that makes it significantly slower than the other valves and sticks a LOT. All repair shops do is take my money and claim they've fixed it when they have done nothing. It is so frustrating. What should I do? And the oil doesn't help with either of these things, which is even MORE frustrating.

- Open up the #4 valve cap and flood the top with valve oil, put the cap back on and turn the instrument over. Put valve oil in the crack where the valve comes out of the bottom of the valve case. This can be hard to see. Put some drops on every moving part of the valve action. I can remember the layout of that valve but I don't think you can shoot oil into the valve. Try all that I said above and see if that helps. Rotate and wiggle the valve between each step.

- Q:From searching around I feel that I need to replace this on my vehicle. Is the Suction Control Valve different from the Idle Control Valve? Sometimes at a stop light the engine will stall. A couple times it has happened while driving when coasting to a turn or stop.

- hold the computer near the Pathfinder it will suck data directly off the internet (NO WAY) what you need is a complete diagnosis by a experenced Technician or a Nissan Technician. Idle control is on the bottom of the throttle chamber or on the intake manifold. Stalling and Dieing may be caused by a Distributor or air flow meter fuel pump or clogged up fuel filter. Suction control valve in not a part on your year pathfinder good lick

- Q:Help! I've got this leaky CPVC valve in a new plumbing setup for a water heater. It only drips when open. :( It's going to be a real pain to replace it. Is there any way to tighten this thing up? It looks like there is a plastic pop off panel on the knob for the valve but I'm not sure. Thanks for any help!

- Turn off the main water to your house. Turn that valve to open. Then tighen the nut on it (slightly), see if the valve will close , if yes; then tighten it a little more, then see if the valve will close. If yes - that should do it. If the nut is so tight that the valve will not close, then loosen the nut just a tad. That should do it, ......... now, turn the valve off. Turn back on the main water to your house -- and see if that works.

- Q:what are the best aorta heart valves. mech. or animal.

- It really depends on the age of the recipient. Mechanical valves last much longer but require blood thinner treatment for life to prevent strokes which has risks and is a pain and most would like to not take blood thinngers. Biological made from pig and cows and cadavers mean people can go back to their lives with no blood thinners. But, they wear out and last depeding around 10-15 years. Most do not want another open heart surgery. It is a conversation between the surgeon, cardiologist, patient and family. A young person, the no-brainer is mechanical if they can maintain blood thinner compliance. An older person would want a tissue valve with less chance of outlving it and requiring another openheart surgery. And perhaps at an age where the surgery wouldnt be done. So the best choice is based on age and what the patient wants. Arnold Schwarnegger chose a tissue valve even though it will wear out before he dies statistically and require a replacement but he didnt want to be on blood thinners. Putting a tissue valve in a 20 year old, then replacing it at 35 with another, then again at 50 and then at 65. Doesnt make sense and the scar tissue from it all. If that doesnt make sense A mechanical valve in an 80 year old and then the risk of a blood thinner and bleeding issues doesnt make sense either. Hope that makes sense

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Swing Check Valve Wafer Type Double Disc Body Material WCB

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords