Suspension Ceilinng Grid System 3600mm Suspension Ceilinng Grid System 3600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized steel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic cold roll forming and punching machineries guarantee the high precision.

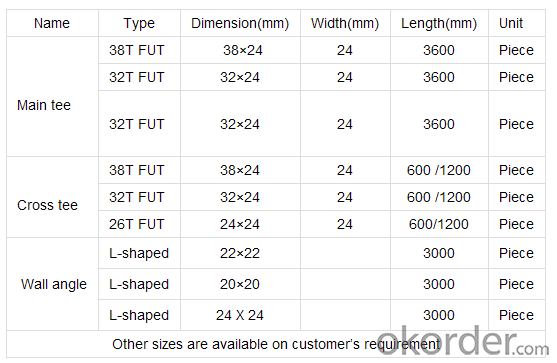

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

- Q:Light steel keel partition keel spacing 300, the number of meters per square meter vertical keel?

- The main machine DC welding machine, electric toothless saw, hand drill, screwdriver, nail gun, line fall, by the foot and so on.

- Q:Is installing a suspended ceiling difficult?

- Well, that depends. Is the power already there and good to go? If you want to install a ceiling fan where a light is currently hanging, there could be problems also. However, assembling and hanging a ceiling fan is easy. E-mail me w/ more details and I can help you. I have installed 100's of fans, literally!!

- Q:My home is over 100 years old. I don't know when the ceiling was put up but it's been painted over a few times I'm sure. It looks like a tiled drop ceiling but I haven't seen any signs of a grid or any type of suspension. The ceiling is about 6 inches lower than it is in the adjoining rooms which are plaster ceilings. Many tiles feel nice and sturdy, but a few are almost paper thin and now have finger sized holes from where I pushed on them. I'm okay to leave as is. I don't want to get into pulling the whole ceiling down. But is there any other way to repair this? It isn't as easy as just swapping out the broken tiles with new.

- These probably do have suspension. I would just leave them the heck alone.

- Q:I am trying to hang a 30 LBS item from a drop ceiling, with no luck. I would like to use 2-3 eyebolts to distribute the weight, but everytime I think I figured it out, it pulls right through. The ceiling can't be very thick at all. Can this be done?

- You won't be able to hang from the grid. What you can do is to get some threaded rod and rod anchors, attach them to the framing above the grid, and then drill a small hole in the tile for the rod to come through for the object you wish to hang. Hope this helps.

- Q:I am planning a November wedding and the reception hall has acoustical tiles and a metal grid that I would like to hide somehow. I am on a tight budget and cannot do anything permanent.

- Inexpensive Ceiling Ideas

- Q:100 * 30 * 20 * 0.8 light steel keel refers to what it means

- Should be J-type unilateral keel, as the wall of the dragon keylone and CH-keel (vertical keel) matching.

- Q:Light steel keel expensive or aluminum alloy keel expensive? What are the characteristics of each

- There is a kind of paint keel is made of iron. Also T-type. But relatively soft. Own grasp.

- Q:Paper gypsum board is B1 grade fireproof material, why installed in the light steel keel can be treated in accordance with A-class fireproof material? Partition wall is to have mineral wool, the ceiling does not seem to need it.

- There are many kinds of gypsum board, there are fire gypsum board, fire gypsum board there are hierarchical, A grade that is gypsum board

- Q:Light steel keel wall noise cotton is asbestos it? Are there any harm?

- Yanmian products are used high-quality basalt, dolomite as the main raw material, after 1450 ℃ high temperature melting after the use of international advanced four-axis centrifuge high-speed centrifugal fiber, while spraying a certain amount of binder, dust, After the collection by the collection of cotton, through the pendulum method, coupled with three-dimensional method of cotton after the curing, cutting, the formation of different specifications and use of rock wool products. Rock wool is a skin irritating cotton product, direct contact with the skin is caused by irritation, such as redness, itching and so on. Other hazards are temporarily unknown. Yanmian advantage lies in the safety of fire, heat insulation sound insulation. Such as other mineral batons are of this nature. If you are worried about sound insulation cotton hazards, you can use polyester fiber sound-absorbing cotton, is currently the most widely used safety and environmental protection sound insulation batt.

- Q:Gypsum board light steel keel cut off how much money 1 square

- Light steel keel skeleton 20 yuan per square meter, gypsum board double-sided 1.2cm thick plus 18 yuan / square, labor costs in about 20 yuan / square, if placed on the noise cotton to add 3, plus loss, other dressings generally About 65 yuan (without paint)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Suspension Ceilinng Grid System 3600mm Suspension Ceilinng Grid System 3600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords