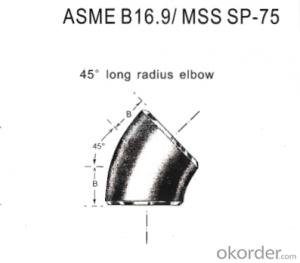

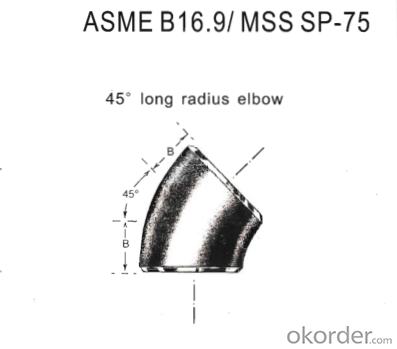

Steel Pipe Fittings Butt-Welding 45° Long Radius Elbows ASME B16.9 MSS SP-75

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features standards and products of our butt welding fittings:

Features of butt welding fittings:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of butt welding fittings:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

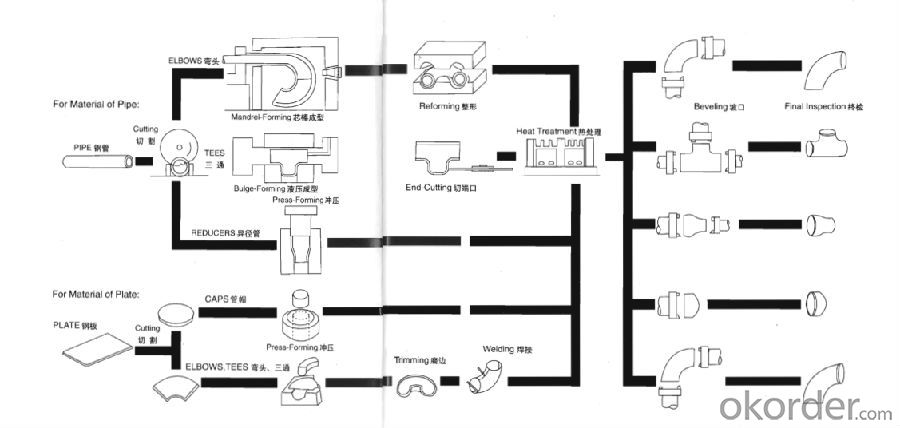

Manufacturing method and process:

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

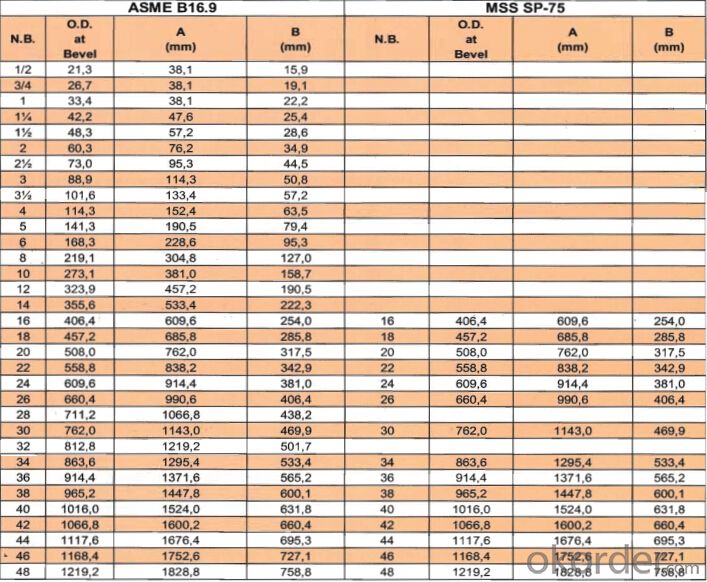

45° Long radius elbows:

Packing of butt welding fittings:

FAQ of butt-welding fittings:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:If a fire were to break out in your house right now, would you know exactly where the nearest one is?

- I . You could also upgrade to 3/4 or 1 PVC to get more stability. 1/2 is sort of flimsy.

- Q:Drawing design, drain cross dry pipe is flexible cast iron pipe, vertical pipe is PVC pipe joint. When it needs to change the diameter, what kind of pipe fittings should be adopted for big head?

- But in actual construction, because the special AD type bottom joint is more expensive, the construction unit usually adopts the cast iron pipe elbow to deal with the problem of reducing the diameter of the two kinds of materials.

- Q:Why does it take so long to extinguish forest fires?

- Buy a book on basic residential plumbing and DIY it of course! I assume you're talking about drain plumbing, not supply plumbing. Basically you'd find a point at which you're confident in the drain and make a plan for replacing all the drain from the toilet to that point. Its going to involve PVC pipe, fittings, and glue, a hack saw, file, screw driver, and possibly a rubber compression sleeve. That's just for the pipe. You'll need access to the drain for the entire length which might mean cutting into drywall, flooring, etc. Provide more details and maybe some pictures for more specific advice.

- Q:I was wondering if a fire blanket could catch on fire, also if other fire stopping things could catch on fire, like extinguishers or baking soda, stuff like that

- A letter home to their parents informing of their safe arrival.

- Q:I thought about taking an old blanket and stuffing it inside my window to keep cold air out. I need some more tips like this; help!

- I would hope that my son wouldn't ASK to pull the fire alarm, he'd just do it. Seriously, when you're in a BURNING building, would you honestly be standing there debating whether or not to pull the fire alarm?

- Q:WHAT IS THE BASE USED IN FIRE extinguisher?

- when your to drunk to stand you fall over and your safely tucked away in bed and in the middle of the night if you roll out of bed then you just roll the other way and your back in bed again.

- Q:In the Bible, does God ever strike down with lightning people who have lightning rods on their tents?

- hey its a website made to answer homework questions try it out its free good luck

- Q:Where is the nearest fire extinguisher?

- Rap is definitely having a negative influence on society. My roommate listens to rap and thinks it is actually music and has a meaning. The worst part is that he listens to songs by artists like Soulja Boy and Lil' Wayne and thinks they are actually music that have meanings. I feel sorry for him because of how shallow he is.

- Q:Now that NBC fired that liar Brian Williams, should FOX follow suit and fire its entire lying broadcast staff?

- cold water avoid scrubbing your skin another thing is baking soda will neutralize acids or other caustic chemicals if it still burning re flush the skin with cold water if it doesn't go away in a few hours or blisters You may want to see a doctor baking soda works very well on caustics hope that helps Lr

- Q:Which is the best CD scratch cleaner?? Please give me a tip to enhance the life of DVD-RW(DVD Rewriter)?Difference b/w DVD-R and DVD+R?

- That sounds like a good idea, although I would replace William regal with maybe randy orton, I love the shield, hope they get a wrestlemaina match

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Pipe Fittings Butt-Welding 45° Long Radius Elbows ASME B16.9 MSS SP-75

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords