Stainless Steel Pipe Fittings Butt-Welding Eccentric Reducers

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Pipe Fittings Butt-Welding Eccentric Reducers

Features standards and products of our Butt-Welding Eccentric Reducers:

Features of Butt-Welding Eccentric Reducers:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of Butt-Welding Eccentric Reducers:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

Manufacturing method and process of Butt-Welding Eccentric Reducers:

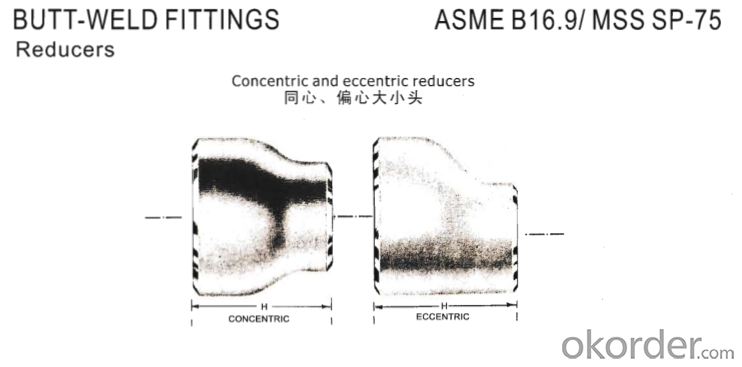

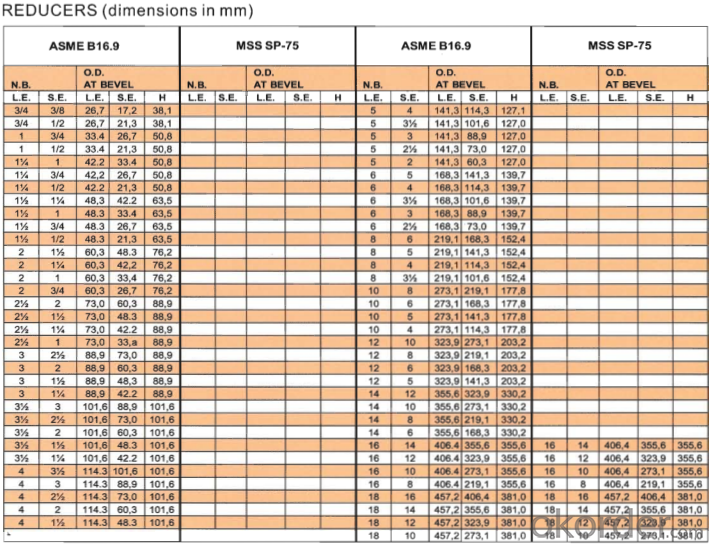

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

Butt-Welding Eccentric Reducers:

Packing of Butt-Welding Eccentric Reducers:

FAQ of Butt-Welding Eccentric Reducers:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q:can you be hynotized even if you are wearing contact lens?

- confusing stuff. query at the search engines. that will might help!

- Q:my kitchen utensils are lost when i need to cook and need them.. so in what container or holder can i place them in. Either being able to find them quickly help

- I'm not sure what your budget is, but since your already using AutoCAD, why not use Autodesk Inventor with the Tube and Pipe Routed Systems Add-In?

- Q:I am the most expensive in town, but it's also true that I offer cageless boarding, an over 400 square feet play room, free 2 walks a day and am a dog trainer/behavior consultant that is pet first aid certified. I also only accept 2-3 dogs so they can get the attention they deserve. Have toys, swimming pool for dogs, and offer 24/7 supervision. Just checking on thoughts for my pricing, thanks!

- Well from growing pot for so many years it is not good to use reflective materials it actually burns the plant too bad. Good Luck!

- Q:Is the hydraulic pipe joint stainless steel or carbon steel?

- Of course, the corrosion resistance can not be done. But wear resistance, machinability is much better than stainless steel. See what parts of your connection are made of

- Q:Why should you keep a fire extinguisher handy when making the classic dessert crepes flambé de l’orange?

- I believe the sizes are the same as ASTM but in mm, internal and external, so for elbow radius. To be sure, try look the web for Anaconda an american company, They have factories in Mexico and Chile and also distribute copper piping for all those regions.

- Q:Until what age is a Dalmatian (dog) Stud fertile? We have a pair of dalmatians but the female can't conceive.

- i think so.. heat both ends until you see them almost melting. put them together. it works better on smaller diameters.

- Q:What kind of clothing do emo girls wear?

- First of all, admitting that your first couple of years are not going to be your best is key. Once I realized in my first year of teaching, that I was not going to be super teacher I felt a lot better. During my second year I still wasn't super teacher. This will be my fifth year and I still don't think I'm there. But knowing it gets better every year is helpful. I always pick a few things I want to change or new things I want to implement. Those things will be very personal to you depending on your grade, level, location, and style. But here is what I plan on doing this year and I teach second grade: improving and frequently changing my literacy centers Adding more fun and interactive lessons to my very scripted reading program how to group my desks in my teeny tiny classroom without feeling crowded improving the way I teach vocabulary

- Q:what should you immediately do when the gas hose catches on fire? details

- Finding the right sized bulk heads is a pain. I know this isn't the best answer there is though what I had to do was take a piece of paper, set it against the hole, shade with pencil so you have the exact size of the hole and go to a saltwater specialty shop and match up the proper bulk heads. A little secret, most people just get pvc pipe fittings with some neoprene on the inside tank side and tighten these. I personally have bulkheads on most of my tanks though I'm drilling a lot more of them soon and I'm just going to go w/ pvc fittings tightened against the glass with some neoprene or other washer type material on the inside.

- Q:If there was a fire and I went to pull the fire alarm what if I read the directions out loud to help me to understand what to do and to make me more confident? Also what if my hand slipped and I had to pull the handle again and I said uh-oh? Do people ever talk out loud to themselves or to a friend standing nearby in this situation? Why is it that someone would do this silently while another one would talk out loud and still get the job done? If a kid were to pull a fire alarm in a fire would they be more likely to talk out loud since it is a new thing for them? What would they say out loud to themselves in this situation to help them?

- We're a single star system. How do we know? Through the usage of telescopes with detectors that monitor very tiny changes in infrared energy (more commonly known as heat). Everything gives off heat. The cosmic background radiation is just above absolute zero and we can detect changes in it to within a millionth of a degree. so if there is a dead star floating around out there, we would know about it. Also, any thing that massive would disrupt planetary orbits. And have been able to detect changes in orbital patterns since the 18th century (read up on how Neptune was discovered).

- Q:I am doing an experiment regarding the fluid flow phenomena. Does anybody come across this experiment mention above? I need some relevant websites which have this informations and the internal design of the valves. Thanks.

- Maybe you can run in a temporary line from the compressor, connected to a branch with a valve. You will have to shut down whatever is on the other end until the connection is made, unless it has a valve fitted for this purpose. Another idea is to get a portable compressor or hire one for temporary use.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Pipe Fittings Butt-Welding Eccentric Reducers

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords