Silicate Board Tiles Waterproof Calcium

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

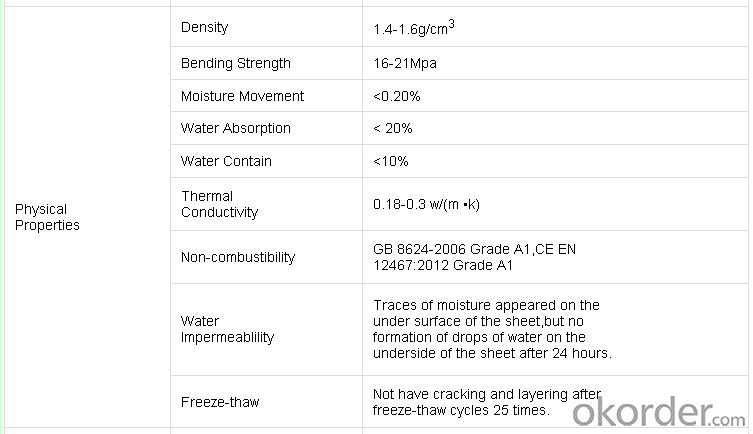

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

Images:

- Q:i am building an outdoor BBQ island and i live in an area that snow will fall for a couple of months. i have been researching cement backer board and i cant find any recommendations on snow fall and what type of tyle is best for this application. dont want to make this investment untill i know what i am getting into. any suggestions

- I built a tile inlay on my deck for my grills. It's held up through 3 Wisconsin winters so far. I used pressure treated plywood for a base, then installed Durock over the plywood. Use Flexbond thinset for adhering the tiles. My neighbor owns a flooring store, and he set me up with an epoxy grout. You have to work it quickly to avoid a mess, but it's very durable. Hope this helps. EDIT: I would recommend using the plywood to give the Durock additional support. If you can enlarge the opening enough to wrap the Durock around the edge, you should be good. The tile and Durock should provide enough protection to keep the plywood from burning. If that will be an issue, you can screw some pressure treated 2x4's along the length of the metal frame, spaced every 16 or so, and then screw the Durock to that. This will give the top support so it won't deflect under the weight of the tile and snow, and keep the tile from popping. Good luck.

- Q:What besides cement board can i use to set tile on?

- Hi Kaitlin, here's a link to a product called Denshield. I like it very well as it's much easier to work with than cement board. I think you could find this product locally.

- Q:We have drywall in our kitchen that was painted with a smooth semi-gloss paint a good 8 yrs ago. We'd like to install 3x6 tumbled marble as a backsplash over the drywall. It's about 1/4 thick so probably slightly heavier than say, the tiny square glass tiles that come on a 12x12 netting. One person at the Home Depot said we could just sand and scrape up the drywall and then apply the thinset and install the marble. Another said we might want to use a cement backing. We aren't really DIYers and would so we don't want to create extra work with the cement backing if it isn't needed. That said, we don't want the drywall to start peeling and the marble tiles to start falling off after a short amount of time. Please advise. Thank you!

- I would recommend screwing wonder board over the drywall before putting the tile up. This will give you a long lasting application. It will not up your cost a whole lot and you will be much happier in the long run.

- Q:Cement fiber wall hanging board PVC wall hanging board which is good?

- Cement fiber board if it comes with insulation, you can stick + anchor technology, do not need to dry hanging ah, save more!

- Q:Installing tile in my laundry room. put down the cement board with a mortar/thin set base under it, then nailed it down according to manufacturer's instructions. The mortar/thin set totally dried then I had to do a few loads of laundry before I was able to put any tile down. Unfortunately one of the hoses hooked up to the washer leaked and soaked the cement board and I'm sure also the sub-floor. Do I need to rip out the cement board and re install before I install the tile? obviously I would need to ensure the floor is fully dry before I install the tile. Thanks

- You shouldn't have to rip it out. I would let a fan run on it for a few hours just to make sure it is totally dry.

- Q:How to install the solution of cement pressure plate

- Plastic buckle plate, plastic aluminum plate production: These two methods for home decoration finished, and want to wrap up the riser. Because it is not necessary to fill the disk, it is convenient. Plastic buckle: wood keel plus angle, directly from the bottom of the buckle up into the installation. Disadvantages: not beautiful. Aluminum-plastic plate: wood keel on the nail nine PCT board, and then all the glue to the aluminum-plastic plate stick to a variety of colors, close to the disk effect. Disadvantages: aluminum-plastic plate angle is easy to crack, should use thicker plate.

- Q:I'm pulling up the linoleum and replacing it with ceramic tile, 12x12. it's a small bathroom, on the 2nd floor.Under the linoleum is wood. Do i need to lie down cement board before I put the mortar mix down? Or will it be fine to put tiles on the mortar mix on the wood?

- You should have a backer of some type. There are a number of options available now so the choice is yours and dependant on the circumstances of your project regarding which one would be best. While many people do install tile directly over a wood sub floor that does not make it right. Tile has considerable permanence. It is somewhat involved to properly install and difficult to remove if the installation is not done correctly. The final outcome of a tile installation, like so many other projects depends largely on the preparation. So many people skip many of the necessary early steps that really do not cost that much extra but make a huge difference on the outcome. Use a backer system. G. Borders Home Repair, Improvement, & Handyman Service Plano Home Repair

- Q:Is the cement board a cement pressure plate? What's the difference?

- Cement board and cement pressure plate is a product of the two names, in fact, no difference. Plate of cementitious materials are cement

- Q:Attic with a channel steel structure, covered with aluminum instead of wood multilayer? Is it feasible?

- Do not need such a complex, directly in the steel structure on the shop 20-24MM thick fiber cement board, and then directly to the floor can be, the floor has a moisture barrier the best pad a layer of moisture, one moisture,

- Q:This would be around the bathtub area. Not sure whether to use the same cement board tape and mortar at the ceiling line or to switch to regular wallboard joint compound. Which is correct? Thanks!

- i think most of the time the boards come in a dimension that puts them below the ceiling line and the difference is filled in with water resistant drywall and finished regularly, then most of the cement board is covered in tile so little finish work is needed on it .. if its all the way up probably just tape it and finish as normal but strictly speaking, the whole layout isnt correct if it terminates at the ceiling joint ..

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Silicate Board Tiles Waterproof Calcium

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords