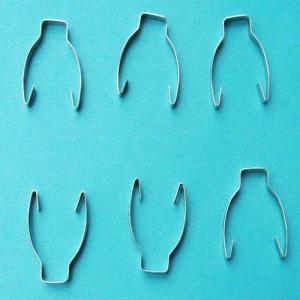

Sheet Metal Multi-Function High Precision Stamped Shrapnel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000pieces pc

- Supply Capability:

- 20000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details Of High Precision Stamped Shrapnel

| Brand Name | MOULDSZ |

| Material | Brass, Stainless steel, BeCu, Carbon steel, bronze, Alloy spring steel, etc. |

| MOQ | 5000pcs |

Specification Of High Precision Stampd Shrapnel

| Material | Brass, Stainless steel, BeCu, Carbon steel, bronze, Alloy spring steel, etc |

| Mould | According customers request to build the mould. |

| Surface treatment | Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, and imitation gold-plated |

| Equipment | High-speed punching machines,Ordinary punching machines,Wire cutting machines,Milling machines ,etc |

Application Of High Precision Staped Shrapnel

Our products are widely used in many files , such as cellphone ,cumputer,switch ,lights ,communication devices ,auto parts etc.

Packaging & Delivery Of High Precision Staped Shrapnel

1.Packaging:with wooden case after fumigation or according to customer's requirement.

2.Delivery : according to your order quantity .

- Q:What's the meaning of the "section difference" in the die design?

- Die design "poor upstairs say no, should say in the section of the draft. For example, 10MM tall things pull 1 degrees angle, that is, the top and bottom of the section, the difference is 0.17 of the difference

- Q:About die design and machining

- A mechanical design (machine design), according to the requirements of the mechanical structure, working principle, motion, force and energy transfer, the various parts of the material and shape size and lubrication methods for design, analysis and calculation and transformed into specific description as a basis for the manufacturing process. 1, mechanical design can be broadly divided into: (1) new design (development design). The application of mature science and technology or experimentally proved feasible new technology, the design of new machinery has never been, mainly including functional design and structural design. (2) succession design. Update existing mechanical designs to improve performance, reduce manufacturing costs, or reduce operating costs based on experience and technical development. (3) variant design. In order to meet the new needs, some modifications or additions and deletions to the existing machines have been made to develop variant products which are different from the standard ones. Two, mold design, mold enterprises engaged in digital design, including mold and die, based on the traditional mold design, the full application of digital design tools, improve the quality of mold design, shorten the period of mould design personnel 1, the main jobs include: (1) - converting 3D digital mapping the product and mold model for conventional processing using two-dimensional engineering drawings, (2) die - digital design according to the product model and design intent, establish relevant mould three-dimensional entity model; (3) the digital simulation analysis of mold according to the product forming process conditions, analysis of the mould parts structure analysis and thermal analysis of motion fatigue analysis and die; (4)...

- Q:What is the major of mold design and manufacturing?

- Main courses: Fundamentals of computer application, manufacturing process of mechanical drawing and tolerance, and application of CAD technology, CAM technology and application, stamping process and die design, plastic molding and plastic mold design, mold, professional English, mould price estimation, NC technology, electrical and electronic technology and electric machine control, electrical assembly practice, production practice course.Occupation qualification certificate and technical grade certificate: PRETCO A-level certificate; national computer information technology examination issued by the Ministry of labor and social security certificates; was issued by the Ministry of labor and social security of the middle and senior technician of vocational qualification certificate; access to provincial and municipal issued by the mold NC machining or mold the design of occupation qualification certificate; access to provincial and municipal occupation qualification certificate issued by pro/e or ug.

- Q:In the processing and design of the mold, the quadrilateral and the single side of that advantage, where are there?

- If all departments have been accustomed to four points in the words, it is recommended not to modify, and before we want to change the company, the result is a mess, especially the discharge department, the mold is big, the number of electrodes can not touch.There will be many unexpected conditions, ha ha... Must change, you can try, but the whole department should be highly coordinated, or you will be exhausted

- Q:What basic knowledge do CNC milling machine software programming and mold design require? Where do you start learning?

- It is recommended to operate machine tools first, and then to study!

- Q:Am I allowed to skip the process and die as a mold designer? I have been working for a month and have a good knowledge of the machining process

- The mold design should have a full understanding of the mold organization and each component

- Q:What is the relationship between industrial design and mold design and manufacturing?

- Industrial design is a big scale.Mold design and manufacture is only a major within the Department of electrical and mechanical engineering, industrial design will not necessarily mold design, mold design will generally be a little industrial design.The so-called relationship, in fact, is the scope of coverage, industrial design covers the mold design, from product design.See below:Industrial Design (Industrial: Design: ID) refers to the design of industrial products on the basis of engineering, aesthetics and economics.Industrial design into product design, environmental design, communication design, design management 4 categories; including design, mechanical design, circuit design, costume design, environmental planning, interior design, architectural design, UI design, graphic design, packaging design, advertising design, animation design, display design, website design etc.. Industrial design is also called industrial product design. Industrial design involves psychology, sociology, aesthetics, ergonomics, mechanical construction, photography, color science and so on. Industrial design and industrial division of labor brought about by industrial design, and other arts, production activities, process production are obviously different, it is a variety of disciplines, technology and aesthetic concepts of the cross product.Mold design and manufacture refers to basic mold design and manufacturing expertise, has strong practical ability, in the production of the first line in mold design, process design, mold manufacturing, mold maintenance, quality management, to adapt to the needs of the production and management of machinery industry and service line, high-quality skilled talents have good occupation ethics and innovative spirit.

- Q:I work as a graphic designer. Now I work for a company that processes mold parts and has been doing it for a year. I think it's time to change jobs

- Hello, are you doing what part of the mold parts, mold baking in recent years less profit, understand the mold, and the mold structure, is a very good product design.

- Q:How many people do machining and die design using CATIA?

- Software for die design, no problem. I've seen a company that's been using it all the time. Software can be used for machining. I've seen a company in use, but I don't recommend using it in mainland companies at present.

- Q:Will the CATIA software be used as two modules for mold design and NC machining?

- I don't entirely agree with the statement upstairs! Purely from the point of view of miaolijin's question, CATIA has a powerful function in mold design and numerical control! CATIA is primarily geared to the automotive and aerospace sectors and accounts for most of the world's share.

MOULDSZ is a versatile manufacturing factory - we specialise in supplying products made to customers` specification. The most important areas of our business are: manufacturing of stamping parts,hardware parts,shrapnels,stamping parts made of aluminium, copper & stainless steel, etc. Also auto parts,household applience spare parts like wash machine,air condition,refrige etc.

1. Manufacturer Overview |

|

|---|---|

| Location | Suzhou, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 2.5 Million - US$ 5 Million |

| Main Markets | Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central, America, Northern Europe, Southern Europe, South Asia, Domestic Market |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | less than 50 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | about 500 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Sheet Metal Multi-Function High Precision Stamped Shrapnel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000pieces pc

- Supply Capability:

- 20000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products