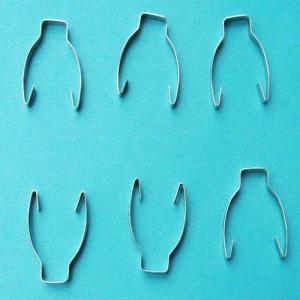

High Precision Stainless steel Copper Casting

- Loading Port:

- Dandong

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Piece/Piece pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Copper Casting

| Brand Name | MOULDDD |

| Place of Origin | Liaoning, China( Mainland) |

| Material | Copper Alloy, Brass, Bronze |

| Finish | Polishing, Ball shotting, Painting, Zinc Painting,sand blast, etc |

| Technology | Precision casting, precision machining |

| OEM Service | Acceptable |

Specification of Copper Casting

| Casting Process | Clay sand casting, furan resin sand casting, shell mold casting; Water-glass sand casting, water-glass investment casting, lost-wax investment casting; Die casting, sand casting, lost-wax casting. |

Application | Machinery part,/Casting/Tractor/Pump Valve/Impeller/Electrical equipment/Auto parts/ Farm machinery/Railway equipment/Mining machinery/Engineering machinery/ Petroleum machinery etc. |

| Equipment | CMM. CNC X-Ray |

| Dimensions | According to customer request |

| Certificate | ISO9001:2000 |

| Inspection | Mechinical Property Inspection |

Usage&Application

Machinery part,/Casting/Tractor/Pump Valve/Impeller/Electrical equipment/Auto parts/

Farm machinery/Railway equipment/Mining machinery/Engineering machinery/

Petroleum machinery etc.

Packing&Delivery

Packing Details: inner cartons and outer wooden box.

Delivery Details: 30 days after order confimationa and deposite.

- Q:What are the commonly used software for die design?

- PROE, always feel that all parameters full related software design out of something better, but also to learn AUTOCAD, the two is enough, there is time to learn CAM programming software, is to understand the process after all, being a good designer, or doing something out of high cost possible unable to process.

- Q:Major in mold design and manufacturing, mechanical manufacturing and automation

- Machinery manufacturing and automation is a profession that will never be eliminated! Relatively speaking, the design and manufacture of mold is relatively high wages, and the trend of development will be "strong"! If I had to choose it now, I would definitely choose the design and manufacture of the die! Of course, career and personal preferences are inseparable from the relationship

- Q:What is the difference between mould design speciality and material molding specialty?

- Both belong to the mechanical engineering, the biggest difference is the material forming method, mechanical engineering mainly research cold processing (machine processing), material forming and control is focused on welding, casting, pressure processing, etc..Mechanical major for cold processing of materials, such as machining, the professional more concerned about the shape of the material on its performance, it focused on the design of materials under different requirements, that is, mechanical design. Both belong to the mechanical specialty, because the molding pays more attention to the material itself, often delimits the discipline to the material institute, takes the material specialty.Material forming and control engineering is the influence of microstructure and macroscopic properties and surface shape in the process of the relevant technological factors of thermal processing change material for molding process, solve the development, theory and method of optimizing process, molding equipment; design theory and method of the research of mold, mold manufacturing, heat treatment, the material processing method.

- Q:Stamping die design and manufacturing thinking and exercises, mold processing relative to the general parts of what features?

- After the completion of the mold manufacturing, it is necessary to adjust and test the mold. Only after forming the qualified parts, the mold manufacturing is qualified.

- Q:I want to teach myself the die design (plastic mould). Please tell me which books I need. What's the title of the book? I'd like to have more details. Thank you

- Buy the foundation of the book, look at the institutions, plastic mold forming and technology, I suggest you do mold apprentice, that can be theory and practice together

- Q:Ask: "mold design and manufacture" and "numerical control technology" are easier for new people

- A part of the numerical control processing of thing die processing technology, NC technology is mostly done machining, engaged in machining with NC programming, NC programming is the office work, has engaged in CNC equipment maintenance, engaged in CNC programming words than the mold design of the treatment is not on the. It all depends on personal interests.

- Q:I am reading materials, molding and control engineering, the choice is the direction of mold processing, and no one can say how the employment direction?

- General bar, mold factory, well, the car companies can also go to see your own strength

- Q:Which work is better for die design and five axis machining center programming? As soon as I graduate, these two positions can be done, mold design and five axis machining center

- Don't dream, want to die from the bench to learn, want to engage in programming from the operation began, the company not to let you engage in design and programming, especially foreign companies, design and programming are a lot of foreign over, don't you sell a.

- Q:Plastic mould design and NC programming

- Yu Dan said, you should absorb knowledge like a sponge. The two must learn, the design work should be studied more deeply, the school only has the foundation, does not apply. Remember, to learn oral English well, you have the opportunity to be a top executive in foreign investment.

- Q:Mould design and manufacture. It's no use learning it. Hurry up! Who will introduce you?

- Want to learn mold design and manufacturing, the mold must be a certain understanding of the structure, it is best to do, and then to learn the design

1. Manufacturer Overview |

|

|---|---|

| Location | Liaoning, China |

| Year Established | 2011 |

| Annual Output Value | Above US$ 10 Million - US$ 50 Million |

| Main Markets | the United States, Germany, Japan, EU and other countries, the majority of users praise and love. |

| Company Certifications | ISO 9001:2008 PED Certificate |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% - 40% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 1,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

High Precision Stainless steel Copper Casting

- Loading Port:

- Dandong

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Piece/Piece pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords