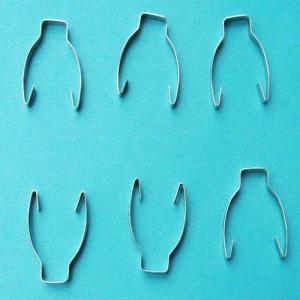

Sheet Metal Parts for Household Appliances

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1Piece pc

- Supply Capability:

- 20000Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Household Appliances Sheet Metal Parts

| Brand Name | MOULDSZ |

| Place of Origin | Shenzhen, China( Mainland) |

| Material | Carbon Steel ,Stainless Steel, Cold Rolled Steel, Aluminum, Brass, Copper |

| Finish | zinc plating ,powdered, or according to customer request |

| Engineering&Tooling |

1. 3 designers in house. 2. AI, SLD, PRT. IGS, AutoCad, PDF, JPEG etc.

|

| OEM Service | Acceptable |

Specification of Household Appliances Sheet Metal Parts

| Quality Control | 1.ISO approved. 2.Inspection at site. 3.Inspection before shipping. 4.testing machine. |

Application | automobile,auto,car,furniture ,household appliances |

| Drawings | AI, SLD, PRT. IGS, AutoCad, PDF, JPEG etc |

| Dimensions | According to customer request |

| Certificate | ISO9001:2000, Mill Certificate |

| Inspection | Mechinical Property Inspection |

Usage&Application

Automobile,auto,car,furniture ,household appliances

Packing&Delivery

Packing Details: Inner plastic bag , outer carton box, and advised by customer.

Delivery Details: 30 days after order confimationa and deposite.

- Q:Would you please tell me the die design is included in the mold production? Don't you just make a design? Do you want to start the mold? Aren't they supposed to be made by mould makers?The mold is very expensive, some hundreds of thousands of sets, some very cheap?

- I study the mold design and manufacture in school, learning plan for each different school to is not the same, some are in the school every time you practice a mold parts processing, when you put the assembly to the graduation processing his entire college parts into a mold, a school is not just. Start is the foundation, begin to learn drawing, wait to go out in the factory it may start as a mould, there may be in the mold fitter is that, in general, mold design, plastic mold molding surface is more expensive, bigger are millions die relatively cheaper

- Q:Looking for a technical school to learn die design

- Guangdong Dacheng senior mold school, founded in May 2004, is the first professional mould design senior combat institution in Guangdong province. It is located in Changan Town, Dongguan, a famous town in china. Do not open other professional, professional plastic mold design, our school aims to let students learn the most practical factory technology.The school is designed with the Pro/E mold design, mold design, UG 2D mold design, mold flow analysis, mold design, export video tutorials and other professional learning. In order to ensure the quality of teaching, fully using the factory as a case of materials. Hired factory actual work for more than 8 years, experienced lecturers, and by a number of backbone enterprises. The school teaching guidance committee to carry out the teaching research work of teachers' teaching quality evaluation of regular periodic inspection, learning for students, lectures and practice of supervision.

- Q:Stamping die design and manufacturing thinking and exercises, mold processing relative to the general parts of what features?

- The mould material has excellent properties, high hardness and difficult processing

- Q:Ask: "mold design and manufacture" and "numerical control technology" are easier for new people

- NC easier, needs a short time, but also a certain ability to learn

- Q:What do the mould design assistant engineers need to know? Master, do me a favor!

- In fact, the key is that you have not done the mold, the mold design engineer must be mold 2D qualifying to the factory to do some mould apprentice actually why don't you learn programming copper down public knowledge is unable to find a job, hard.

- Q:What are the differences and connections between die design and mechanical design?

- The main tasks included:(1) digital mapping - converting 3D products and mold models into two-dimensional engineering drawings for conventional machining;(2) digital design of die - based on the product model and design intention, establish the 3D solid model of the mold;(3) digital analysis and Simulation of mold - according to the forming process of the product, the structural analysis, thermal analysis, fatigue analysis and movement analysis of the die parts are carried out;(4) simulation of product forming process injection molding and stamping forming;(5) custom design process for standard parts and standard design of moulds;(6) die production management.

- Q:What are the requirements for a mold design?

- You need a good education, and you have a lot of experience.

- Q:I am a fresh undergraduate student. I have just learned how to deal with the die design. How about the treatment? Do you know what to say?

- Buddy, you are very cattle, undergraduate students dare to use, proficient in two words.I think the undergraduate design is still more competitive, now do the design of undergraduate students is not a lot, so you should find that pay more attention to education, of course, generally companies can also learn in, often small companies can learn to complete things, I want to do an undergraduate design probation period should be around 2500.Start the study period, lower your head and lower your body. I hope it works for you.

- Q:How many people do machining and die design using CATIA?

- Mold processing or processing with Cimatron and worknc CATIA, I did not use, ha ha!

- Q:Will the CATIA software be used as two modules for mold design and NC machining?

- For complex metal stamping die and plastic mold and related mold flow analysis, stamping analysis, related software is in good accordance with CATIA!

1. Manufacturer Overview |

|

|---|---|

| Location | Suzhou, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 2.5 Million - US$ 5 Million |

| Main Markets | Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central, America, Northern Europe, Southern Europe, South Asia, Domestic Market |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | less than 50 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | about 500 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Sheet Metal Parts for Household Appliances

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1Piece pc

- Supply Capability:

- 20000Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords