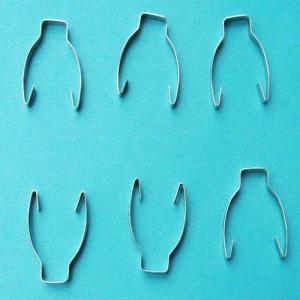

Aluminum Die Casting Car Parts, High Quality

- Loading Port:

- Dandong

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500piece pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details Of Aluminium Die Casting Car Parts

| Brand | MOULDDD | Material | Aluminum Alloy, Zinc Alloy, Mg Alloy, Brass, copper Alloy etc |

| Process | trim,grind,drill,CNC | Surface | chrome plating, sandblasting, painting |

| Quality Control | Industry CT Scanning,3D x-ray technology | MOQ | 500pcs |

Specification Of Aluminium Die Casting Car Parts

| Material | Aluminum Alloy, Zinc Alloy, Mg Alloy, Brass, copper Alloy etc. |

| Surface | Zinc plating, Abrasiva blasting, Spray, Powder coating, painting, |

| Quality Control | Industry CT Scanning,3D x-ray technology, coordinate-measuring machine |

| Process | Casting, Deburring, Machining, Surface Treatment, Packing,all per request |

| Main Machine Used | Die casting equipment,CNC center, lathe, milling,etc. |

Applications Of Aluminium Die Casting Car Parts

Auto parts, machinery parts, household parts, Cooker parts, furniture parts, etc

Applied software PRO/E, Auto CAD, Slid Work, CAXA, UG, CAD/CAM/CAE

Furniture Of Aluminium Die Casting Car Parts

1. Product Material: aluminum alloy or per customers' drawing needs.

2. Surface Treatment: chrome plating, sandblasting, painting, anodizing, powder coating, electrophoresis,etc.

3.Sample time:20~ 30days.

4.24-hour service with prompt reply

5.Process: trim,grind,drill,CNC.

Packaging & Delivery Of Aluminium Die Casting Car Parts

packaging : packing with the plastic film and Carton .

Delivery : according to customers' order quantity .

- Q:What are the majors of NC machining and die design? Specific point

- Your degree is to engineer class, to deal with iron so on

- Q:Mold design and manufacture, post employment direction

- The employment is the main mold design, mold manufacturing industry sales assistant, mold designers, draftsmen, mold fitter, Turner, Xigong, CNC machining programming operator etc.

- Q:Looking for a technical school to learn die design

- Guangdong Dacheng senior mold school, founded in May 2004, is the first professional mould design senior combat institution in Guangdong province. It is located in Changan Town, Dongguan, a famous town in china. Do not open other professional, professional plastic mold design, our school aims to let students learn the most practical factory technology.The school is designed with the Pro/E mold design, mold design, UG 2D mold design, mold flow analysis, mold design, export video tutorials and other professional learning. In order to ensure the quality of teaching, fully using the factory as a case of materials. Hired factory actual work for more than 8 years, experienced lecturers, and by a number of backbone enterprises. The school teaching guidance committee to carry out the teaching research work of teachers' teaching quality evaluation of regular periodic inspection, learning for students, lectures and practice of supervision.

- Q:What's the future of the mold?

- Many people first thought is to go to school or training institutions of this kind to learn, there are equipment ah, ah teacher heard he is very pleased with oneself, really can let yourself from that after the meteoric rise. Not really! In many places, tuition is only 3000-6000, and some are even lower! But you must think about it, the mold design really good learning, should be able to design independently of the mold! Rather than just talking about it, draw some lines in the various 2D3D software! Don't think so, you will learn, if give you a mobile phone shell products to you design mold, light will draw lines from a hair ah! So, learn mold design, first do not expect to learn what software, which teach software which section, software is just a tool, as long as any software design, can quickly reach a formal final mould design drawings on the line, now the main 2D is CAD, 3D is the main UG, PROE, followed by SOLIDWORKS CATIA, etc.. Learn mold design, light is the key to learn mold design technology itself, and the actual masters in the design of factory working experience! Without this, even if you can all the world's software, 3D, 2D, can you?! The factory can only act as a draftsman! The salary is at most 2000. Is that your goal? No You must master the design skills of the die and some masters' own design experience, so that you can succeed in order to get a high salary! Want to learn mold design, want to enter the mold industry, you first want to see which mold the most promising, the scope of the mold is very wide, but only the most promising plastic mold! Plastic mold is mold...

- Q:What are the types of moulds? What is the main job of mold design? Does mold design need to be opened, such as machining centers, CNC machine tools, or design before a single computer?

- Single process die, compound die, continuous die. Mold design is to use UG software for a single design.

- Q:I want to teach myself the die design (plastic mould). Please tell me which books I need. What's the title of the book? I'd like to have more details. Thank you

- Buy the foundation of the book, look at the institutions, plastic mold forming and technology, I suggest you do mold apprentice, that can be theory and practice together

- Q:In the processing and design of the mold, the quadrilateral and the single side of that advantage, where are there?

- If all departments have been accustomed to four points in the words, it is recommended not to modify, and before we want to change the company, the result is a mess, especially the discharge department, the mold is big, the number of electrodes can not touch.There will be many unexpected conditions, ha ha... Must change, you can try, but the whole department should be highly coordinated, or you will be exhausted

- Q:What do the mould design assistant engineers need to know? Master, do me a favor!

- You have to understand a lot of places, in front of me, you are rookie, assistant is not necessarily someoneYou have to have a strong 3D key modeYou have to have a high 3D partingYou have to have good group 2D standing upYou have to understand the processing procedures, design in line with the actualOh, these you will, you can take charge as chief of personnel.

- Q:I am a fresh undergraduate student. I have just learned how to deal with the die design. How about the treatment? Do you know what to say?

- ..... Boy, you're so naive. I'm a graduate of 07. As a mold apprentice, CNC apprentice, maybe you asked me why I didn't do the mold design? Not so simple, because the community company recruit experience, mold design apprentice, but not get round you see your luck, in short, no relatives and friends do die with you, it is best not to have wise remark of an experienced person.

- Q:Mould design and manufacture. It's no use learning it. Hurry up! Who will introduce you?

- It can be said to be useful, but it can also be said to be useless!Useful well, these are common sense, should understand, understand the day after work is very helpful!Say no use, the knowledge is too common, the level of use is still a great distance!

1. Manufacturer Overview |

|

|---|---|

| Location | Liaoning, China |

| Year Established | 2011 |

| Annual Output Value | Above US$ 10 Million - US$ 50 Million |

| Main Markets | the United States, Germany, Japan, EU and other countries, the majority of users praise and love. |

| Company Certifications | ISO 9001:2008 PED Certificate |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% - 40% |

| No.of Employees in Trade Department | 200 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 1,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Aluminum Die Casting Car Parts, High Quality

- Loading Port:

- Dandong

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500piece pc

- Supply Capability:

- 5000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords