OEM Precision Customized Aluminum Metal Stamping Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000pieces pc

- Supply Capability:

- 20000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details Of Metal Stamping

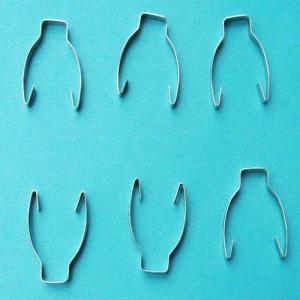

| Brand Name | MOULDSZ | Material | Stainless steel |

| Coating | Zinc plating | Size | Different size can do |

| MOQ | 5000pcs | Port | Shanghai |

Specifications Of Metal Stamping

| Material | Stainless steel, steels ,aluminum alloy, red copper, brass, bronze alloy, etc |

| Processing | Mold designing, stamping, stretching, deep drawing, bending, welding, plating, assembling and packaging. |

| Coating | nickel plating, zinc plating, chrome plating, gold plating, acid pickling, etc. |

| Production | Supply more than 10,000pcs per day with one mold |

Features Of Metal Stamping

1) With thickness from 0.1-0.4mm

2) High precision

3) Digital camera contact and cell phone contact

4) Mainly applied in battery contacts, locks, machinery, home appliances and electronic products

5) The products range is continuously being broadened

6) We make every endeavor to develop towards high precision and highly

sophisticated to satisfy customers' requirements

Application Of Metal Stamping

Electric meters, shunts, temperature controllers (thermostats), mutual inductors, current transformers, relays, transformers, sound ,car GPS ,Car chargers, etc

Packaging & Delivery Of Metal Stamping

1.Packaging:with the waterproof paper or do as your need .

2.Delivery : according to your order quantity .

- Q:What are the commonly used software for die design?

- See what you want to engage in the industry.. plastic parts and stamping parts are generally pro/e.., have not seen any car cover, the use of mold pro/e, usually UG, and some catia...This also has a certain influence with the place.. Guangdong by Taiwan there, with more pro/e...

- Q:What's the meaning of the "section difference" in the die design?

- Die design "poor upstairs say no, should say in the section of the draft. For example, 10MM tall things pull 1 degrees angle, that is, the top and bottom of the section, the difference is 0.17 of the difference

- Q:What are the majors of NC machining and die design? Specific point

- Out, you can programming CNC, you can operate CNC, you can do fitter, you can do mold design. But it all starts with internships and apprenticeships. Good luck。

- Q:CAD die file for die pressing die design

- This thing will do a jump die, there are two small punch, if the compound die is easy to break, we rushed through this thing, size approximation

- Q:Looking for a technical school to learn die design

- It is better to learn IT class salary is really much higher, but tuition is more expensive, ah, I also graduated from college, nothing learned, see those who did not read junior college directly read IT out, is 4 thousand and 500, really envy ~!

- Q:What is the flow of mold design?

- A question is hard to say in strict terms. Every factory has the tactics of each factory! A set of mold also has a lot of design methods, but also depends on manufacturers requirements, product quality requirements and die prices!

- Q:What basic knowledge do CNC milling machine software programming and mold design require? Where do you start learning?

- It is recommended to operate machine tools first, and then to study!

- Q:What do the mould design assistant engineers need to know? Master, do me a favor!

- Answer your previous question, do the design of the mold without dismantling the brass, but must be ranked and parting. Direct ranking has a lot to do with the amount and assembly of the product, so it is recommended that you be a good designer, you have to have a good head and understand the boss's mentality. Because the poor position will affect the product production and processing costs.

- Q:What does "2D" in the die design mean? What is the main idea?

- Mold design refers to the digital design enterprises engaged in mold, including mold and die, based on the traditional mold design, the full application of digital design tools, improve the quality of mold design, shorten the period of mould design personnel. Mold designers can work in the fields of numerical control programming, mold 3D design, product development, 3D design and so on.

- Q:How should numerical control be combined with mold design?

- As for the combination? Now many molds need to be processed by numerical control machine tools, but numerical control is not limited to the mold, for example, the metal or other material parts can be machined directly.

1. Manufacturer Overview |

|

|---|---|

| Location | Suzhou, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 2.5 Million - US$ 5 Million |

| Main Markets | Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central, America, Northern Europe, Southern Europe, South Asia, Domestic Market |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | less than 50 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | about 500 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

OEM Precision Customized Aluminum Metal Stamping Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000pieces pc

- Supply Capability:

- 20000 Piece/Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords