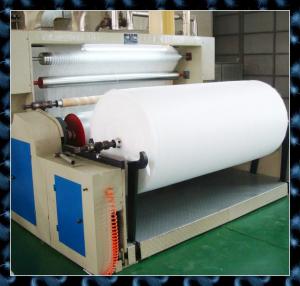

Sample Warping Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 100 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Sample Warping Machine

1. Working width:max.2200mm

2. Warping yarn speed:0-1000m/min(depending on yarn diameter , ends / cm and type o

Packaging & Delivery of Sample Warping Machine

Packaging Details: standard seaworth transportation packing

Delivery Detail: 60 days

Technical indicators of Sample Warping Machine

1. Working width:max.2200mm

2. Warping yarn speed:0-1000m/min(depending on yarn diameter , ends / cm and type of yarn)

3. Warping length: min 7m --max.700m (depending on yarn diameter , ends / cm and type of yarn)

4. kinds of yarn: wool, cotton, synthetic, silk and other knids of yarn

5. Warp density:min.4ends/cm---max.240ends/cm

6. Automatic leasing device

7.16 colour selection(16 accumulaters)

8. Stopping device for yarn breakage

9.beam speed: max.30m/min

9. Personal computer( with textile design software)

10.beam device

- Q:What is the ripple?

- Synthetic fiber fabric can be printed directly after embossing. To the carved with a concave copper roller as a hard roller, the surface of the high elastic rubber roller for the soft roller rolling fabric process, called copy flowers.

- Q:What is the difference between the shuttle spinning machine and the rapier textile machine?

- Rapier production than the old car, with the workers less than the old car, reducing the labor force, ease the recruitment difficult

- Q:What is the role of the parchment loom?

- Decisive in the reed that place is generally not light pulp heald frame high arrow arrows with burrs and so on

- Q:What is steaming technology?

- Steaming finishing is the use of wool fiber in the hot and humid conditions of stereotypes

- Q:What is wrinklng?

- In addition, the use of special wrinkling equipment, the formation of special shape of the wrinkle effect, such as claw and walnut

- Q:What is the characteristic of the shuttleless loom?

- The Therefore, the use of shuttleless looms for the increase in fabric varieties, adjust the fabric structure, reduce fabric defects, improve fabric quality, reduce noise, improve the working conditions of great significance

- Q:How does the shuttleless belt adjust the belt?

- 5. Bottom line crochet should not be removed when the bottom line crochet, the bottom line cam spring, cam roller fixtures, etc., to reduce wear and tear.

- Q:What is velvet?

- Chloe finishing is the use of wool felting to make wool fabric tight and thick hair on the surface of the process, also known as shrink it

- Q:What is the difference between rapier looms and air-jet looms?

- Air compressor has a problem, all machines have to stop production.

- Q:What is the difference between air-jet looms and water-jet looms for weft storage?

- In several shuttle looms, air-jet loom is the highest speed of a kind, due to weft induction is reasonable, high latitude rate, easy operation and safe operation, with a wide variety of adaptability, less material consumption, high efficiency , High speed, low noise, has become the most promising new one of the cloth.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangyin, China |

| Year Established | 1999 |

| Annual Output Value | 10-30Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9002 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 10000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Sample Warping Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1Set set

- Supply Capability:

- 100 Set Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords